Help separating coupler |

Post Reply

|

Page 12> |

| Author | |

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Help separating coupler Topic: Help separating couplerPosted: June-03-2008 at 8:28pm |

|

Hey everyone, I'm new here. I recently bought my first Correct Craft, a 1989 Martinique. Bear with me because this is also my first inboard. Well I am trying to do an alignment. I saw Eric's how to and I think I understand everything. But the problem is that I can't get the coupler to separate. I took out the 4 bolts and tried to pull back on the propeller and hammer around the coupler with a wood chisel. This did nothing, so I tried a few other methods. I soaked it in PB blaster then tried to use a wood block to hammer the propeller backwards and I sprayed the strut bushings with wd-40. I even tried to heat it up and use a come along to separate it. It has still not moved at all, it's like it's fused together. I have spent a few hours just trying to get this coupler to separate and am getting frustrated. The odd thing is the coupler doesn't even look rusted but I doubt that the previous owner ever aligned it which is why I am doing it now. Any other I ideas on how to get this to separate? I am ready to just put it in the water and throw it in reverse. Just kidding. Thanks in advance for the help. -James

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-03-2008 at 9:10pm Posted: June-03-2008 at 9:10pm |

|

James, I noticed you posted the same problem over on PN. We're always happy to see someone come over to CCfan. Welcome.

They can be stubborn to get apart. The old wood chisel because of it's sharp edge is the best bet and you may just need to hit it harder. I know our trans specialist Eric tries to get a putty knife in between the coupling halves first. If the wood chisel fails, then you need to get the cold chisel and a bigger hammer out! If you mushroom the face a little with the cold chisel, you can clean it up carefully with a flat file. It may not look rusty from the outside but it may be inside. There is also a pilot shoulder on the face that maintains concentricity that may be rather tight. Try the bigger hammer! This is a flange spreader used for pipe flanges. I don't feel it would fit between the flange and the trans but the idea could be used to make up something similar.

Eric? comments? |

|

|

|

anthonylizardi

Gold Member

Joined: July-25-2007 Location: DFW, TX, USA Status: Offline Points: 836 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-03-2008 at 11:21pm Posted: June-03-2008 at 11:21pm |

|

I used a pnewmatic chisel with a round tip and hit it in the area where the flange goes up. I used a slight angle to induce some rotation. It made a dent on the metal but at least the flange is fine. Even with a pnewmatic chisel it took a while. I try to put different lubricant in the strut bearing but the best thing was water. And to removed the couple the only that worked for me was using the socket in between with longer bolts. That was a lot of work.

|

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-03-2008 at 11:59pm Posted: June-03-2008 at 11:59pm |

|

Thanks for the suggestions. I managed to get the coupling to separate. I was able to get it apart by using a putty knife and also sharpening the chisel. I also hit it a little harder. However what I found was a little disheartening. The alignment was waaay off. The whole driveshaft was about 1/2" to the left of the engine and the coupling was a little crooked compared to the engine. I will try and get pictures tomorrow. I'm just glad that I found the problem now and didn't just bolt it back up because I couldn't get it separated. Upon further inspection it seems that what is causing this is a twisted strut. Luckily the shaft looks OK although it is hard to tell. Is the strut repairable or do I have to replace it? I think I may just be better off replacing it though because the cutlass bearing is oddly worn because of the way the shaft didn't go straight through. What is involved in taking off the strut? Do I have to pull the driveshaft? I wasn't sure if I should start another topic because these are different questions. I can do that if necessary. Thanks. -James

|

|

|

|

behindpropeller

Platinum Member

Joined: July-31-2006 Status: Offline Points: 1810 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 12:34am Posted: June-04-2008 at 12:34am |

|

OR:

Loosen the mounts and drop the front of the engine until it pops loose. Anytime you hit that shaft that goes into the tranny you are wearing onthe bearings and may damage your shaft. Tim |

|

|

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 7:49am Posted: June-04-2008 at 7:49am |

|

James, Glad you got it busted loose and didn't use a slide hammer!!

Here's 3 pages of a thread thats a good one to sit down and read. It started as a prop shaft removal but gets into shaft straightness and bent struts. Take a look at it and of coarse if you have any questions, make sure you ask. Some great pictures too. thread to read |

|

|

|

stepper459

Senior Member

Joined: June-17-2007 Location: United States Status: Offline Points: 349 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 12:54pm Posted: June-04-2008 at 12:54pm |

|

So is this a stupid question... Why do we not all put anti-seize or something similar between the coupling and the transmission when re-installing, so the next time you go to take them apart it's easier? Or do you think by the time the coupling comes off again there would be no trace of any lubricant left? Or maybe it's a fine idea going forward but any boat you have to deal with that has not had this done is still a PITA to separate the two? Or am I behind the curve and this is common practice?

|

|

|

|

behindpropeller

Platinum Member

Joined: July-31-2006 Status: Offline Points: 1810 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 12:57pm Posted: June-04-2008 at 12:57pm |

I put never-seize on everything in the boat when it goes back together. Tim |

|

|

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 2:10pm Posted: June-04-2008 at 2:10pm |

|

[QUOTE=stepper459] So is this a stupid question... Why do we not all put anti-seize or something similar between the coupling QUOTE]

It's not a stupid question. I agree that it is a good practice. The factory doesn't do it because it costs more! |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 3:15pm Posted: June-04-2008 at 3:15pm |

|

A stuck coupling is a good sign of correct alignment, unbolted one this morning and they automatically seperated cause of mis-alignment

(even though they dont come apart easy, still check the alignment on re-assembly) |

|

|

"the things you own will start to own you"

|

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 8:56pm Posted: June-04-2008 at 8:56pm |

|

Thanks for everyone's feedback. That thread was very helpful. I just have a few questions. I haven't taken anything apart yet so I don't know if my shaft is bent or not. But if it is bent, on that thread it was recommended to get a new shaft and coupler from general. Where can I find more information about this company, like how to contact them? My other question is, what is the bolt and socket method to removing the coupler? I kept seeing it mentioned but didn't see any details about it.

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 9:15pm Posted: June-04-2008 at 9:15pm |

|

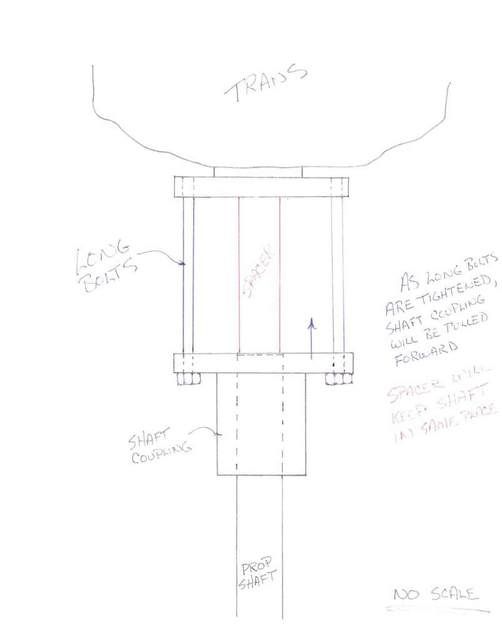

James, Here's a sketch I made and posted awhile ago. Sorry I'm not a CAD type and had to do it the old fashion way with paper and pencil!!

One thing that's not on the sketch is you can use fully threaded bolts (or all-thread)with extra nuts so you don't need a bunch of different length bolts. |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2008 at 10:45pm Posted: June-04-2008 at 10:45pm |

|

use the search feature for the phone#

|

|

|

"the things you own will start to own you"

|

|

|

|

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-05-2008 at 1:18am Posted: June-05-2008 at 1:18am |

|

James, My Mustang had a bent strut when I got it and since I didn't know any better and CCF wasn't around 20 yrs ago,I took it to a prop shop in the Fla Keys.Turned out as good as new.Seems that people hit bottom there alot,and the shop had plenty of experence.

|

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-05-2008 at 10:17pm Posted: June-05-2008 at 10:17pm |

|

Thanks for everyone's help. I am in the process of trying to press the shaft out of the coupler using the bolt and socket method. Unfortunately it's not going very well. I haven't given up yet though and I will keep everyone updated.

|

|

|

|

GottaSki

Grand Poobah

Joined: April-21-2005 Location: NE CT Status: Offline Points: 3365 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-06-2008 at 2:42pm Posted: June-06-2008 at 2:42pm |

|

Bolts-and-socket will only warp the flange. Good luck aligning it afterward.

You are close to only needing a sawzall to continue. |

|

|

"There is nothing, absolutely nothing, half so much worthwhile as messing around with boats...simply messing."

River Rat to Mole |

|

|

|

anthonylizardi

Gold Member

Joined: July-25-2007 Location: DFW, TX, USA Status: Offline Points: 836 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-06-2008 at 2:54pm Posted: June-06-2008 at 2:54pm |

|

I try different ways and the bolt and socket was the only one that got things started. I finished with a bolt puller. I would like to hear other good ideas. For the next time.

If you use the socket method make sure you applie the same preassure to all 4 bolts. You can tell right way because it will bet harder to turn the shaft. Be patient, use plenty of WD40, and to get things moving ti takes a good preassure. At least mine was a PITA, I used an impact gun and set the preassure to the lowest setting. IMO, equal preassure was the key. |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2008 at 10:36am Posted: June-07-2008 at 10:36am |

|

If they are that tough you have to put even pressure on them and heat (being very careful) dont even try to pull them off if the set screws are snapped off, you have to drill them for relief,

|

|

|

"the things you own will start to own you"

|

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2008 at 12:39pm Posted: June-07-2008 at 12:39pm |

|

Thanks, I tried all the suggestions mentioned. It still hasn't moved at all. First I tried the bolt and socket method, it didn't budge even after I got the bolts so tight that I broke one of them. Then I started getting desperate so I unbolted the rear of the engine from the engine mounts and used a come along to lift the back of the engine so I would have more room to work. Then I was able to get this heavy duty timing gear puller on there. I cranked that down until I couldn't get it any tighter. This is after I soaked it PB Blaster. So I tried heating it and tapping it with a hammer and then I tried to tighten it some more. Nothing. So I have given up. I am assuming that if the boat took a hit hard enough to bend the prop and strut that the shaft is probably bent too. So I am just going to cut it out with a hacksaw.

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2008 at 1:05pm Posted: June-07-2008 at 1:05pm |

|

James, Sorry to here that it's been a real problem. I've had problems too and in one case had to pull the engine to get the shaft out forward. Since you have the come a long, is the set up heavy enough to pull the engine? The hacksaw isn't going to be fun ether! If you do need to cut the shaft, at least go a borrow or rent a Sawsall.

|

|

|

|

SNobsessed

Grand Poobah

Joined: October-21-2007 Location: IA Status: Offline Points: 7102 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2008 at 10:17pm Posted: June-07-2008 at 10:17pm |

|

James - welcome to the stuck coupler club - I just went thru that myself.

I found out (thanks Boat Dr.) that stainless steel (shaft)has a higher expansion rate than carbon steel (coupler) so heating it only makes it tigher! |

|

|

“Beer is proof that God loves us and wants us to be happy.”

Ben Franklin |

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-12-2008 at 4:07pm Posted: June-12-2008 at 4:07pm |

|

Sorry it's taken me so long to reply. There was a big storm on Long Island and I lost my internet. I'm actually using a friends computer right now. I did manage to get the shaft out though. It was not fun. I started using a hacksaw and was getting nowhere fast. So I borrowed a friend's grinder and sawsall. I used the grinder most of the way and then used the sawsall to finish the cutting. Well I just dropped the parts off at the propeller shop and will hopefully have the boat back together soon. Well I guess the benefit of this whole ordeal was that it was a really good learning experience and I learned a lot about inboard boats. I have one more quick question though. When I took the strut off I noticed that there were cracks in the gelcoat as well as a few cracks inside the boat around the bolts. I really have no experience with fiberglassing. Should I just leave it or should I do some kind of repair to the cracks?

|

|

|

|

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-12-2008 at 4:18pm Posted: June-12-2008 at 4:18pm |

|

well doesn't sound good but can you post some pictures of them so we can see how bad it is around the holes. Might not be something to worry about but with it being on both sides then that could be all of the way through and not just the gel cracking on the bottom and in that case something needs done.

sounds like PO might have hit something at one point and time. |

|

|

|

gigem75

Senior Member

Joined: November-12-2005 Location: United States Status: Offline Points: 239 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-12-2008 at 6:59pm Posted: June-12-2008 at 6:59pm |

|

after hitting a submerged tree I finally gave up and used a cutting torch, on stainless it is not so much melting as it is burning the metal away. Was then able to get the short shaft out of the coupling with a big press. Had the coupling faces trued up on a lathe after all the abuse it took.

|

|

|

|

SNobsessed

Grand Poobah

Joined: October-21-2007 Location: IA Status: Offline Points: 7102 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-13-2008 at 12:55am Posted: June-13-2008 at 12:55am |

|

“Beer is proof that God loves us and wants us to be happy.”

Ben Franklin |

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-14-2008 at 10:18pm Posted: June-14-2008 at 10:18pm |

|

Some pictures of the damage:

|

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-14-2008 at 10:24pm Posted: June-14-2008 at 10:24pm |

|

Thanks for the link SNObsessed. So I guess I should just try to grind down to bare fiberglass to see if the fiberglass is OK. I don't have a dremel tool but I have a small grinding bit that goes on a drill. Would that be OK to use to grind off the gel coat? After I get down to bare fiberglass hopefully everything will look OK. Then to fill the grooves I will use some Marine Tex. I will probably be able to do this tomorrow or on Monday. I will report back with my findings.

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-14-2008 at 11:33pm Posted: June-14-2008 at 11:33pm |

|

James, Marine Tex is one of those "does it all" products. It may do it all but not very good at anything!! As a filler maybe but not in a structural fill. Billy Mays should be selling the stuff. Stick with a basic marine epoxy system like West or Mas. After exposing the damage, post some pictures.

|

|

|

|

SNobsessed

Grand Poobah

Joined: October-21-2007 Location: IA Status: Offline Points: 7102 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-15-2008 at 1:33am Posted: June-15-2008 at 1:33am |

|

James - I put down 3 overlapping layers of cloth on the inside of the hull, just to reinforce the area. If you have them precut, you can put them down with 1 mix, just saturate them 1 at a time. Boater's World had MAS epoxy onsale for $15 a while back. I was impressed with how easy MAS was to work with. Get the medium speed.

PS - Grind the area down to get thru the grey paint - also you should be pretty well down to the bottom of the cracks so your epoxy can penetrate into good substrate. |

|

|

“Beer is proof that God loves us and wants us to be happy.”

Ben Franklin |

|

|

|

JamesE

Groupie

Joined: June-03-2008 Location: United States Status: Offline Points: 79 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-15-2008 at 7:42pm Posted: June-15-2008 at 7:42pm |

|

Some pictures of the cracks on the inside after grinding off the paint:

What do you guys think? Should I now grind off the gel coat so I can see the other side of the fiberglass? I will do this if necessary but I am really hesitant to grind away the gel coat. The other problem is I don't have a tool small enough to only grind away a small amount of gel coat. I have the grinding stone I mentioned but that is between 1/4" and 1/2" wide. But I guess that would still work. Thanks for everyone's help. |

|

|

|

Post Reply

|

Page 12> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |