Show me your garage

Printed From: CorrectCraftFan.com

Category: General Correct Craft Discussion

Forum Name: Off Topic

Forum Discription: Anything non-Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=15903

Printed Date: May-05-2024 at 4:17am

Topic: Show me your garage

Posted By: C-Bass

Subject: Show me your garage

Date Posted: November-25-2009 at 3:29pm

|

I'm currently in the planning stages of a detached garage, and just want to hear any ideas/suggestions from others willing to chime in. Throw up a pic of your garage as well if you have any.

Right now I'm planning on a 28'deep x 36'wide garage with a 9' door and a 16' door. Roof will be attic trusses to give me storage over the whole 36' length. It will sit on a block foundation and the floor will be poured concrete. I am investigating the idea of installing an I-beam across the 28' length to use for lifting the boat, engine, or for any other project where I need overhead lifting. I'm not planning on finishing it out with insulation and drywall right away to save some cost. I will do those things and time & money allow. Lets hear any thoughts from those of you who have done a grage/shop project. What did you do that worked well, what would you do differently, ...etc... ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Replies:

Posted By: TRBenj

Date Posted: November-25-2009 at 3:37pm

|

Ive yet to plan mine out, but all the recommendations Ive heard on the topic say to go bigger than you think you'll need. This is especially true on the depth with our boats- its nice to have some breathing room to walk around the boat without having to take the platform off, fold the trailer tongue, etc.

Not sure what youre planning for door height, but Id go at least 8', if not taller. Ive had a few boats come very close to not fitting through a 7' tall door, cant fit my truck under one with the roof boxes on either. That will come into play with a newer boat with a tower if you ever upgrade as well. If you can, go with tall ceilings inside. Having to crouch down to avoid hitting the ceiling while working inside the boat is a back breaker. I definitely like the I-beam idea- it would let you hang the boat or yank an engine much easier. Not sure what youve got in mind for electrical and plumbing, but Id add 220V service if at all possible in case you want to run larger tools (compressors, welders, etc). A wash sink and a urinal would also be most welcome to avoid having to trek back in the house. ------------- |

Posted By: WakeSlayer

Date Posted: November-25-2009 at 4:06pm

|

I have a 40x80 polebarn. 54 feet cold, and a 26 foot heated shop. We have an enclosed heated stall on one side towards the left rear corner of the cold area for storing my wife's car. The building is 14' high at the bottom of the roof. That enables me to have a mezzanine area on top of the car stall for storage. 12 foot door allows nearly anything to be backed in there, including a towered up SuperAir. I put 200A service in so any power is a non issue. I store 4 boats with plenty of room to keep the plow truck and other crap inside in the winter. I have water back to an outdoor hydrant.

My oversights or mistakes (whichever way you want to look at them): -no indoor water, just outdoor. -no bathroom (Mrs. Wakeslayer hates this) -high efficency furnace, this is a problem in that: a) I do not have a floor drain and they make a LOT of water when it is cold out, b)I can only turn it down to 50*. You cannot let these freeze as you will crack the heat exchanger. If I had a normal furnace, I would actually use less propane by keeping it at a lower temp. Not exactly high efficiency in my case. As Tim said above, go bigger than you think you will need. The more space you have the more stuff you will accumulate. I don't care what you think now, that will always happen. Get a nice inexpensive used fridge for beer. Upgrade a TV in your house, and put the old one out in the shop. DirecTV adds dishes at no charge, and another reciever is only $5 per month. ------------- Mike N 1968 Mustang |

Posted By: 81nautique

Date Posted: November-25-2009 at 4:15pm

Tim's pretty close but he forgot the coffee pot and the fridge for later  . Both are essential for extended garage stays. . Both are essential for extended garage stays.

If I could only have one thing though it would be an overhead beam or beams to support a boat flip, an engine pull or hanging the boat for trailer removal. I would also try to set aside an area that can be closed off, washed down and ventilated so I had a clean area to work with finishes. Even if it was closed off with clear plastic that would be fine, and must have GOOD LIGHTING. And just maybe an upstairs office/man cave with internet access so you don't have to keep running back in the house to get on CCfan for reference material. ------------- |

Posted By: WakeSlayer

Date Posted: November-25-2009 at 4:20pm

|

I have a phone line run to my building and used to be able to get internet access, however, the wire broke underground and the bastard phone company wants $1500 to fix it... Not worth it in my opinion.

Agree on the I beam, that would be awesome. ------------- Mike N 1968 Mustang |

Posted By: C-Bass

Date Posted: November-25-2009 at 4:21pm

|

I'm definitely going with 8' tall doors, for the obvious height concerns and because they will match the house. I forgot to add that while I won't be finishing the garage, it will have a 220V (100amp) run off of the main 200amp house service.

The whole size thing has just kept growing, and I'm really hesitant to expand it more, although I would like to obviously have more room than I'll ever need. The only thing I may change is increasing the depth of it to 32'. The ceiling height is a big issue, especially with the idea of the I-beam. By the time you figure in the height of the beam, the trolley, and then a chain hoist, you're hanging down pretty far and it limits how far you can raise a boat. I want 10 foot studs on the walls, and I'll probably have an extra row of blocks put down on the foundation to raise the wall height up some more just to make sure this isn't an issue. And the urinal...that's genius ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: C-Bass

Date Posted: November-25-2009 at 4:26pm

|

I would probably go with the separated space pole barn space like you have Mike, if it weren't for the covenants of the addition. They're not allowed.

Great ideas so far guys, thanks for the input. ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: WakeSlayer

Date Posted: November-25-2009 at 4:27pm

|

A urinal only works 3/4 of the time, and your wife will not really appreciate it at all. Go with a full unit. ------------- Mike N 1968 Mustang |

Posted By: TRBenj

Date Posted: November-25-2009 at 4:33pm

Come on, Alan- he's asking about construction questions. I figured the beer fridge/kegerator was a given! I love the cable tv and internet idea too. Having an office to house reference materials and other paperwork would be ideal. ------------- |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 4:36pm

|

Craig,

Consider running Pex tubing in the slab now for future hydronic heat. If you do, don't forget to insulate under the slab and at it's perimeter. It's not a bad idea to insulate it anyway otherwise the cold will penetrate in from the outside. At a span of 32', the min. W beam height needed is 14". A - W1426 will give you better than a 2 to 1 safety factor if you are lifting 4 tons. (they aren't called "I" beams anymore!!) ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: behindpropeller

Date Posted: November-25-2009 at 4:44pm

|

Craig-

I did not read all of this, so it may be a repeat. My dad's shop is built with 2x6 walls. On the outside of the studs there is a 1" piece of foam and then steel siding. In the middle of the studs it has fiberglass insulation. On the inside of the garage there is another 1" piece of foam and then T-11 siding over it. In the summer the shop stays about 65 without A/C. In the winter it really never falls below 45 in there. It is very inexpensive to heat. You might consider this when you design yours. Tim ------------- |

Posted By: C-Bass

Date Posted: November-25-2009 at 5:03pm

Haha, I figured you'd bust me on the terms Pete, I was just using the term that everyone knows, instead of wide-flanged beams  . .

I am not a civil engineer, so explain how you come up with a minimum beam height of 14"...is this from the assumed weight of 4 tons, or is there a minimum height based strictly off of the span? If it's based off of 4 tons...take that down to about 3000lbs, I don't need to lift 3 boats at once, just one at a time  . You could probably even rate it for a 2000lbs single point load in the middle and it would be plenty safe for lifting a boat...about 2800lbs split over two equal loads only about 4' from the supports. . You could probably even rate it for a 2000lbs single point load in the middle and it would be plenty safe for lifting a boat...about 2800lbs split over two equal loads only about 4' from the supports.

...I need to polish up some of my statics skills...so excuse me if I'm sounding stupid  ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 5:20pm

|

Craig,

I thought I'd mention the "I" VS "W" because I got busted the other day. I'm old school too!! Per the charts, regarding the "W" beam (I almost slipped there!!) it's the 32' span and not the load that designates the 14" height. If you went to a 30' span, then you could drop down to a 12" height. FTI, a - W1422 (lightest 14" W beam) beam at 32' will give you better than the 2 to 1 for 3 tons. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Hollywood

Date Posted: November-25-2009 at 5:24pm

|

With the tall ceiling, you are going to lose a lot of heat I'd seriously consider heating the floor like Pete said. ------------- |

Posted By: C-Bass

Date Posted: November-25-2009 at 5:25pm

|

Hmmm...didn't know there were any codes on the minimum height for a given span. You have an electronic source I can peek at?

I was really not wanting any taller than a 10" beam...I think I run out of height below it as I mentioned above with the trolley and hoist. I may have to look at a higher ceiling or scrapping the beam idea altogether. As always Pete, thanks for the info. ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: C-Bass

Date Posted: November-25-2009 at 5:32pm

|

Good point Hollywood...although at this point heating & insulation is on the back burner...no pun intended. I guess I should consider this option before I get too far into this. The biggest factor is the $$$ at this point. My main goal is to get a roof over the boat and to plan this structure to allow finishing/upgrading as time and money allows.

------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 5:39pm

|

Craig,

You can do some searching for beam loading but I've never been able to find anything of value. I don't feel the load charts are published anymore due to liabilty issues. They want you to hire a certified structural engineer!! My info is out of engineering reference publications I've had for 20 years. The loading charts aren't code related. Regarding the height issue (under the hook) keep in mind you only need 5" to 6" of beam below your ceiling. Check the min. beam height needed for the hoist trolley you plan on using. Edit: Try to squeeze the foam slab insulation and pex tubing in now. It will really pay off later. It's not that big of a cost. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Hollywood

Date Posted: November-25-2009 at 5:43pm

|

You can mount the beam above the joists, it'll take away storage but you can lift all the way up to them them with hoists and hardware out of the way. ------------- |

Posted By: C-Bass

Date Posted: November-25-2009 at 5:56pm

This is the whole reason I started this thread...thanks fella's. This is the whole reason I started this thread...thanks fella's.

I don't know why but I had stuck in my mind to keep the beam all below the ceiling. Mounting it up into the ceiling as you've suggested would give up a little storage, but it would really only make a small divider up in the attic. You could still step over it easily. ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: WakeSlayer

Date Posted: November-25-2009 at 6:07pm

|

I agree with what Pete is saying. Plan well and add just enough so your future plans will fit in as your budget allows. I left a couple things on the table and doing them now would cost considerably more to retro-fit than just doing it the first place.

Also, I lose a ton of heat in my shop because of the 13.5' ceiling. I would rather have dropped it down 4 feet and had more mezzanine storage. It costs me a fortune to heat my shop. Rework sucks. ------------- Mike N 1968 Mustang |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 6:09pm

|

Craig,

I mentioned the 5" to 6" below the ceiling just incase you ever wanted to drywall the ceiling. BTW, the W beam in that position will interrupt the wall double cap plates. Your framer would then need to add auxilliary cap plates on the outside of the wall in the boxed eaves. They should extend at least 5' on both sides of the beam. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: behindpropeller

Date Posted: November-25-2009 at 6:10pm

|

I would not put the beam in the attic. We have a beam down the center of the shop and use it to hang all kinds of things.

You can find surplus beams all over the place if you look hard enough. Another option is to put two beams along the side and put in a trolley so the beam is not in the way. If money challenged I would still focus on the insulation and heating in the floor, unless you plan to just build it as cold storage. Tim ------------- |

Posted By: harddock

Date Posted: November-25-2009 at 6:15pm

|

Go as high as you can. My garage(36x32) has the 14" beam but unfortunately building it with guidance from my father (who didn't believe in height) I lost considerable height under the beam. We actually took out 5 floor joists to allow enough height four a 4 post lift. I would go for the radiant floor heat if you plan to run the heat all winter. Oherwise you'll need to drain. I have forced hot air and it's only on if I'm going to be out there working. Plenty of light, piped air, and electrical receptables are a must. 10ft wide doors minimum. Trimed out, a 9' door is aboy 8'9" and backing a 8'6" trailer in can be tight. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=4487" rel="nofollow - 1998 Ski Nautique |

Posted By: C-Bass

Date Posted: November-25-2009 at 6:20pm

|

Are you saying the 5" to 6" so the drywall would run right up to the web? I think this is what you meant in the previous post about leaving the clearance for the trolley...that makes sense and I think it would look nice.

As for the cap plates, this would only interfere if the beam spanned into the wall. If it stops right at the wall, this wouldn't matter, if I'm thinking correctly. I have not given much though as to what the supports will be for the beam. Any ideas? The cleanest look would be to have the support be in-between the studs that way you could drywall over it. Now that I think about it, this is the situation where it would interfere with the cap plate. ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: 81nautique

Date Posted: November-25-2009 at 6:21pm

You need a wireless router Mike, I've been known to float in the pool with a beer and my laptop. ------------- |

Posted By: Hollywood

Date Posted: November-25-2009 at 6:23pm

|

I sure hope Kristof doesn't have an ethernet jack in his bathroom either. ------------- |

Posted By: C-Bass

Date Posted: November-25-2009 at 6:37pm

|

Tim...interested in hearing why you think raising the beam into the attic a little bit is a bad idea. You would still be able to use the beam in every way that you would if it were hanging down completely below the ceiling.

------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: scottb

Date Posted: November-25-2009 at 6:47pm

| You may not want to insulate right away, but you should consider insulated garage doors. It's easy to add insulation to the walls/ceiling later, but a pain to insulate/replace the garage doors. |

Posted By: Hollywood

Date Posted: November-25-2009 at 6:48pm

|

It really just depends on your needs. A trolley system gives you the flexibility to move things around after they are hung but a beam in the attic will be fine for lifting Pete's 8,000 lb boat straight up. ------------- |

Posted By: behindpropeller

Date Posted: November-25-2009 at 6:57pm

The beam in our shop does two things. 1. It supports the floor on the second story. 2. It is a good place to lift stuff. ------------- |

Posted By: behindpropeller

Date Posted: November-25-2009 at 7:02pm

|

Here is a side cut of what it looks like:

Just guesses on the measurements. ------------- |

Posted By: tullfooter

Date Posted: November-25-2009 at 7:23pm

|

I love the in floor heating, I have it in my house addition. If you are not going to insulate for a while, consider low intensity infrared tube heating. We have it in many areas of our non-insulated warehouse and production buildings. It works great for heating the objects, not the air. ------------- Play hard, life's not a trial run. '85 BFN '90 BFN White Lake, Michigan |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 7:39pm

Craig, Yes, the drywall then runs right up to the web. Metal tabs are welded to the web every 4' so a 2x4 drywall nailer can be screwed on to the length of the beam. A 4x6 post IN the wall is the cleanest and yes, this is when the cap plates are interrupted. If it's not in the wall then the posts being inside will actually take away from the 32' depth. You then also need to tie it to the wall someway - it needs the lateral support keeping the post plumb. If you want the beam centered in the OH door, then of course you can't put a post there! BTW, I'm giving you all my design tricks/solutions for my up north shop that I plan to build this spring!!  (that's of course if CQ gets going on converting my old fashioned pencil drawings to CAD!!!!) I've got 4 pages of specs ready for bid packages and 3 contractors lined up. (that's of course if CQ gets going on converting my old fashioned pencil drawings to CAD!!!!) I've got 4 pages of specs ready for bid packages and 3 contractors lined up.------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 7:45pm

It's not for my boat, it's for yours!!  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 7:59pm

|

Craig,

Now with Tim's structure is when you would really need the services of a structural engineer!! Even if you only have the basic inspections in your area, they would demand it! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 81nautique

Date Posted: November-25-2009 at 8:26pm

That will work nicely, how do I order? ------------- |

Posted By: Gary S

Date Posted: November-25-2009 at 8:59pm

|

A friend of mine just built a new house and has the floor heated in the garage. Some how it uses a standard hot water heater.He had the driveway plumbed also but had to have the concrete redone and didn't have time to redo the pipeing. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: Gary S

Date Posted: November-25-2009 at 9:14pm

Mike, how far is your building from the house? Does the electric feed come from the house also? You have DSL service? There might be a way to get your internet out there- http://asoka.traxbarn.com/Ethernet-Adapters/Products/residential-pluglink/menu-id-64.html?idx=1&prodId=35 - Plug link Let me know ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: p/allen

Date Posted: November-25-2009 at 9:35pm

------------- Pat http://i175.photobucket.com/albums/w146/72ccfan/100_5977-1.jpg - My 72 Skier Rock River Dixon,ILL. |

Posted By: peter1234

Date Posted: November-25-2009 at 9:37pm

|

always leave a pull pipe for wires

slant the floor for drainage and rinsing plan for heat. (put radiant tube in the floor for future heat.)$600 now not possible later always a beam if i could do any one thing in hindsight it would be to pour in pull points for dragging in and out and for pulling repairs. oh one last thing a funnel in the corner that drains into a bucket or stone.. no not for oil ------------- former skylark owner now a formula but I cant let this place go |

Posted By: WakeSlayer

Date Posted: November-25-2009 at 9:49pm

Gary and Alan, Wireless won't reach far enough, nor work very well through the tin walls. Unfortunately, for this instance, it is 800-900 feet. I bought the wire for the phone and the power and trenched it in 5 years ago. I had phone and DSL back there for about two years and then it failed. The phone company claimed that I had been sold crappy wire, which broke, and they wanted $1500 to replace it. I have not tried to hook it up with the other wires (that may well be intact) but after last winter wishing I had access constantly, I may try it. edit: electric service comes from the pole, not my house. ------------- Mike N 1968 Mustang |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 10:05pm

|

Gary,

The use of a standard hot water heater is a common "quick and dirty" method for small areas of hydronic heating. All you really need is a small circulation pump. Not very efficient but it works. Pat, I'm understanding the beam is parallel to the trusses running between them. Craig stated in his first post he wants the beam across the narrow (depth) dimension of his planned garage. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: p/allen

Date Posted: November-25-2009 at 10:13pm

|

Pete

Ok I seemed to have missed that part . From my experienc of building a house with attic trusses, my lower cord was a 2x10 anyway . so your beam does not need to stick up into your floor space . ------------- Pat http://i175.photobucket.com/albums/w146/72ccfan/100_5977-1.jpg - My 72 Skier Rock River Dixon,ILL. |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 10:16pm

That's funny. The phone company told me the same thing about the wire I used when I wired my complete house. It was about 25 years ago and about the time when you were allowed to do it yourself. The employee who came in to wire off my network interface told me it would never work. It's still working today!! Even on the U-Verse!!! I got the strong impression that the employee was pissed that I did his work and he wasn't getting the OT!! He was not a "happy camper". ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 8122pbrainard

Date Posted: November-25-2009 at 10:36pm

In cold areas you need to be real careful with pitching the floor especially if you don't have heat in the floor. Due to zoning restrictions in certain areas, floor drains may not be allowed. (The fear is gas going down the sewer) So, the normal garage floor pitch is out the garage OH door. If it's cold outside and water is running to the door, I've seen the door bottom seals frozen to the floor!! You also do not want a garage floor drain running to a septic system. Drain trenches just in front of the OH door is a partial answer but they may need to go to a "French" drain. Again that may not be allowed in certain areas plus French drains can freeze up too. Speaking of heat in the floor again, make sure your expansion joint between the garage slab and the apron is directly below the OH door(s). You need it to act as a thermal break at this point too. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 62 wood

Date Posted: November-25-2009 at 11:05pm

|

My garage ... 32'x48' , 2x6 walls-10 foot tall, 8' high doors. I also insulated the inside of foundation with 3" styrofoam before pouring floor. ....

Water is a must, add the 220 volt on demand water heater, you wont be sorry. Two floor drains - NOT in the center of the bays, makes it a PITA to roll creapers. Keep them to one side or end. Would of had a bathroom, but we live in the country, so you can guess. I considered in floor heat, but its only good if you maintain the shop temp you want to work at all the time. If you keep it cool, you have to plan hours in advance to work. Plus, in October we had a Saturday morning with snow, I had heat in minutes. I talked with an "infloor heat friend" that morning and he was freezing , as he hadnt started it yet for the season. I went with a high efficiency furnace, I keep it around 50 degrees all the time. Nice thing is when I want to work, in 20 minutes it can be 65. I tried different "low" temps, down to 40, but recovery time is too long, everything is cold and furnace cycles much more, 50 seems to be the sweet spot. I did build it in a closet so if i ever decided not to heat the whole shop, I could just heat the furnace area with a small heater....BTW, dont think that will ever happen! I finished the walls and ceiling in drywall. Painted everything with exterior house paint... VERY durable and waterproof! 8 foot flourescent ceiling lights in all of the shop. Also installed ten 500 watt halogens, about 8 foot off floor, on three walls at one end...great for finish work! Make sure to "zone" your lights so yo dont have to have them all on at once. Trusses are setup for a future overhead crane system. (when time permits) Finish with cable TV, "mondo" stereo system, Cherry wood cabinets, I never want to go in the house!  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1117&sort=&pagenum=6" rel="nofollow - 64 American Skier 62 Classic.. 73 Ski Nautique |

Posted By: Gary S

Date Posted: November-25-2009 at 11:17pm

hmmm- I need a floor pan,you need some wiring, springtime road trip? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: WakeSlayer

Date Posted: November-26-2009 at 12:30am

Dude, Your setup has so many similarities to mine. Country livin'... Mrs. Wakeslayer refers to herself as a Polebarn Widow in the winter. Gary, Pan is here whenever you are ready. Was just thinking that a couple days ago. Mike ------------- Mike N 1968 Mustang |

Posted By: 8122pbrainard

Date Posted: November-26-2009 at 5:43pm

|

In anticipation of breaking ground this spring for my up north shop, I have been building up components going into the shop.

I don't like pipe clutter so the compressed air supplies are going in the wall. Here's the regulator/quick connect boxes I built up starting with 6x6 pull boxes. They will be flush mounted into the 2x6 walls. The two small boxes are the outlets to high mounted hose reels. Compressed air supplies to each of the regulator boxes will be "home runs" in 1/2" ID pex.

A 6x6x4 box sounds big until you start putting in all the guts. It got a little tight especially the one on the right that has the extra exit that will go through the wall to a outside quick connect.

To eliminate more clutter, the dust collection ducting is going in the attic. Then dropping through to blast gates at the ceiling. The majority of the equipment is on mobile bases which gives me more shop layout flexibility but, I needed a means of quick connecting the duct at the ceiling. Move equipment to the side, take down the dust ducting and you have a clear area. This is one of the quick turn and lock blast gates I'm in the process of building. The bottom of the 5' section of spiral pipe has handles so the it's inserted into the blast gate and locked without the need of a ladder. The blast gate is opened with a slotted end broom stick.

Two of the dust drops are close to the wall (floor sweep and compound miter) but being close to the underside of the roof needed some special elbows to clear and match the 12/5 roof pitch just above the ceiling. Since no one makes 22.5 and 67.5 long radius elbows, I had to start with 90's, cut at the needed angles and weld collars to the cut ends.

With the exception of the two "W" beams at the ceiling, keeping the ceiling clutter down helps tremendously with even light distribution. I'm shooting for 150cp per sq. ft. at max light (3 light levels) using T5 HO's. T5's are the latest and greatest - they are replacing HID industrial fixtures!!! More light and 1/2 the power! BTW, the shop is getting a bathroom. Steve is absolutely correct regarding the thermal lag on the hydronic in slab heat. It's the only down side so just like he said, it's not good for quickly bringing up shop temps. Figure on a couple hours for a delta T of 20. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: uk1979

Date Posted: November-26-2009 at 6:13pm

|

I would like to build a workshop with this one day just need to put plenty of battens in for shelves, and your be warm as toast.

http://www.buildingwithawareness.com/blog/2009/04/the-pros-and-cons-of-straw-bale-wall-construction-in-green-building/ - Straw Barn ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: MartyMabe

Date Posted: November-26-2009 at 6:25pm

Among Pete's other attributes he speaks German too!

I know what you're saying it was me having a blonde moment I guess. ------------- 66 Skylark http://www.correctcraftfan.com/diaries/details.asp?ID=5041" rel="nofollow - 93 SN If you're not living in NC, you're just camping out! |

Posted By: uk1979

Date Posted: November-26-2009 at 8:35pm

|

Pete ducting out a shop is a pain we found this to be a good way to go,for cuts and bends just cut a few mm longer and peen over then clip.

http://www.ducting-online.co.uk/shopdisplaycategories.asp?id=92&cat=Clip+Ducting+System - Clip Ducting ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: gun-driver

Date Posted: November-26-2009 at 11:39pm

|

Heres my new toy box.

40' wide 35' deep two story. Walls sit 2 courses above floor for ease of hoseing off floor. Ceiling is 12' high with one 16'W x 10'H door and one 12'W x 10'H door. Heat is radient floor(no cold floor, hot ceiling problems) The joist are open web truss spaning front to back(no poles) Second floor is all open space soon to be office and work shop.

|

Posted By: eric lavine

Date Posted: November-27-2009 at 10:33am

|

one trick i could pass on, is the city at times will not let you put floor drains in, well, before you concrete you lay all the drains out and concrete over the previously installed lowered grates. after the finals you bust the concrete on the grating and you have a drain....unless your like Pete and just hand the inspector an envelope ------------- "the things you own will start to own you" |

Posted By: 62 wood

Date Posted: November-27-2009 at 11:17am

Eric and Pete, whats this thing you talk of... "inspector"? ... thats part of the reason I live in the country.

Ive completely gutted and remodeled our house, with 2 additions, built my new garage, shingled 5 outbuildings, and never had to deal with a permit or inspector. Man life is good in the sticks! A quick note on the infloor heat... absolutely one of the best heats ...again as long as you maintain your work temperature. I actually thought about using it and foced air, but costs would have been out of line. With my high efficency force air I will say, that having insulated my foundation before pouring the floor, my floor, while not as warm as the infloor heat, is never a cold issue. I ran a 16" main heat line off the furnace plenum, to a distibution box in the center of the attic. From there 6" lines run out to individual heat runs in the ceiling around the perimeter of the outside walls. After 6 years...I would do it the same. It works for my situation. BTW, nice toy box Paul! . ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1117&sort=&pagenum=6" rel="nofollow - 64 American Skier 62 Classic.. 73 Ski Nautique |

Posted By: 8122pbrainard

Date Posted: November-27-2009 at 11:22am

Roger, Thanks for the info. I did look at the "Quick fit" clamp type of ducting. Over hear there are basically two systems. A lighter gauge that you can peen over by hand and a heavier gauge that requires a hand crank seamer (not available to rent). Both the cyclone manufacturer and the quick fit duct manufacturer said that with the lighter system you're right at the limits of the static vacuum the collector is capable of producing. I didn't want to take the chance of collapsed duct work in a relatively inaccessible attic. With the heavy gauge, the price is considerably more than spiral. I am trying to maintain a budget so I'm going to have to do some fighting with the connections! They can be a challenge! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 8122pbrainard

Date Posted: November-27-2009 at 11:24am

I'm wearing a hard hat when I come to visit yourself and Pam!!!  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 62 wood

Date Posted: November-27-2009 at 11:36am

|

The hardhat hooks are hanging just indside the door. LOL

Dont even get me started on some of the idiot inspectors we've dealt with thru the years. They should make them work as an apprentice, in the feild for five years before giving them their badge. uuhhhh, and Pete, dont worry too much, after working in the construction field for over 35 years, I think Ive got a handle on the "basics".  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1117&sort=&pagenum=6" rel="nofollow - 64 American Skier 62 Classic.. 73 Ski Nautique |

Posted By: eric lavine

Date Posted: November-27-2009 at 11:42am

|

Steve, post your address, will get one over thier first thing ------------- "the things you own will start to own you" |

Posted By: 62 wood

Date Posted: November-27-2009 at 11:54am

|

Thanks for the offer Eric, but you cant get here from there...

A few of the CCF guys have been over...and all have been able to leave under their own power... LOL FWIW, there ARE building codes here.... just no pesky inspectors out of the city limits...within, thats a different story. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1117&sort=&pagenum=6" rel="nofollow - 64 American Skier 62 Classic.. 73 Ski Nautique |

Posted By: uk1979

Date Posted: November-27-2009 at 12:22pm

|

Pete I know how hard it is to set the ducting up in a tight shop always something in the way, when I first got started used Pvc underground piping and bends just need to well ground as the static build up is high but worked, if your running a high cfm fan I found the indirect drive to be not so loud to run.

------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: Gary S

Date Posted: November-27-2009 at 1:46pm

|

I just had a new roof put on the house and garage. I guess with the building boom over in my area, they must have let go on the inspectors or kept one for major jobs, because my contractor was to take pictures and take them over to the village hall ?? How would you know the pictures were of the job your now on ? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: 8122pbrainard

Date Posted: November-27-2009 at 4:54pm

|

Roger,

The collector I've picked out is a direct drive 5HP. It's going into the utility room along with the boiler, on demand HWH, air compressor, compressed air drier and heat recovery ventilation unit for the shop. A 24" x 24" return duct with a filter grill will get the collection air back to the shop. I feel it's going to be pretty quite but I plan on lining the return duct with the egg crate type sound absorbing sponge. Gary, Are the inspectors really that busy? The ones I've dealt with and still do on about a monthly basis, are the normal "won't get off their fat a$$" unless they really have too types. It's going to be interesting when the economy finally hits some of the municipalities and some of these good for nothing employees start feeling the pinch. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: uk1979

Date Posted: November-28-2009 at 9:12am

|

[QUOTE=8122pbrainard] Roger,

The collector I've picked out is a direct drive 5HP. It's going into the utility room along with the boiler, on demand HWH, air compressor, compressed air drier and heat recovery ventilation unit for the shop. A 24" x 24" return duct with a filter grill will get the collection air back to the shop. I feel it's going to be pretty quite but I plan on lining the return duct with the egg crate type sound absorbing sponge. Pete I found a lot depends on how well the fan is balanced, if it doesn't come with vibro pads it sit on, it may be worth a look round where you work for some off an old machine, and yes the stick on foam works well we have two filter bag systems here because of the mdf dust we make they have a return air gate for the winter. ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: 8122pbrainard

Date Posted: November-28-2009 at 10:22am

|

Rodger,

The cyclone I've chosen is a Oneida brand. I have a friend who has one so I've heard them run and they are quite for a collector. No vibration because they do balance there impellers. With any blower, most of the noise is from the high tip speed of the impeller so most of the noise comes out with the exhausted air but they use a backward inclined which adds to a low Db. The Oneida isn't a bag unit but rather has a large pleated canister type filter (permanent/cleanable) so I feel the filter itself provides quite a Db reduction plus they have a silencer internal of the filter. http://www.oneida-air.com/pro_2000.php - Oneida air On the suction side, I feel the duct work being in the attic and insulated will really knock down most of the noise from that end. It should end up being a very quiet running system. I've got a good source for vibro mounts just in case! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: uk1979

Date Posted: November-28-2009 at 4:52pm

Pete Looks a good home set up you have there,I think the picture shows it has rubber bungs on the legs,I would be interested what you think of it when its up and running. ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: 8122pbrainard

Date Posted: November-28-2009 at 5:51pm

|

Roger,

So you feel it's a "home" unit? The thing is 9' tall!! I don't feel 1400CFM at 6.5" of vacuum is all that bad and that's with the filter!! That's enough to run a planer, jointer and table saw at the same time. I figured the 3 pieces running just in case there would be two people in the shop at one time. (I might need a helper to push my wheel chair around!!) I'm not building a bag house here!! The stand is optional. I'm going with the wall mount bracket that comes with it. It opens up the access to the 55 gal drum plus it's substantially built. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: uk1979

Date Posted: November-28-2009 at 6:21pm

Pete Believe me you can never have enough suck!! just pulling your chain its a nice bit of kit you soon get your own back working on floatation on the SN sea and fresh water so easy on the red pen and see me stickers when I post. ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: emccallum

Date Posted: November-28-2009 at 9:49pm

|

Glad I dont live in the cold! You guys sure spend a ton of time and dough on heating. I have a ten gallon or so propane tank. Last me about two years!

A couple of thoughts on garages from a country boy: Make it as deep as you need for the longest boat then add a few feet. Make it as wide as the wife will allow. That way you can pull things in and out easy with out having the item you need most packed in the back of the shop! Make sure the floor will drain, and tell the concrete finisher, he doesnt get paid until you flood it with the hose to check the drop. I like one big door, rather than two doors if possible. That way you dont have to kill yourself to squeeze something in. Make sure the garage door is a high lift door if you are planing on having a car lift. That way you can have the door open when you lit a vehicle. They generally cost more b/c they need an extra panel or two. If you are puting in a floor mounted lit make sure the concrete is thick enough and the trusses are spaced properly in the area for the lift. It will always be a foot too small no matter how big you build it! |

Posted By: 8122pbrainard

Date Posted: November-29-2009 at 11:10am

Ernest, My AC costs me more per month than my heating! I don't feel the area I live in even comes close to the AC needs of the southern areas. Natural gas last January: $93 Electric last August: $235 ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: SNobsessed

Date Posted: November-29-2009 at 11:29am

|

I'm starting to get garage envy. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: C-Bass

Date Posted: November-30-2009 at 11:38am

Wow...gone 4 days for the holidays and missed out on 3 pages of garage discussion. Lots of good info to take into consideration guys. Much appreciated  . .

------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: 75 stang

Date Posted: November-30-2009 at 12:51pm

|

I built mine 40 x 80 x 14'tall, it has a 10x10 door for my dually and small stuff and a 12x 13'h door for the motorhome and the occasional truck. I built a mezzanine 8x80' to store motors and parts on and built the bathroom and work benches under that 8' high. Its insulated and heated and the trusses I made myself out of 2" pipe on 10 foot centers. You can hang car bodies or boats from the trusses on 10' centers. When i get the other boat done that is the plan to conserve floor space, make a winch system that will pick them up to the ceiling so I can have the floor space back.

We used to build pipe buildings back when pipe seconds were cheap. I dont have any pics of it right now but its pretty plain right now. I want to sheet the ceiling with white metal and add more insulation this winter to make it easier to heat. The neighbor has a hip roof style garage, i always wantet to built one like that and winch the bioat into the upstairs for the winter. Would take some thought on the floor system but it would be cool. ------------- Take your work seriously, not yourself. http://s133.photobucket.com/albums/q70/Bigblockbandit/Lake%20and%20boats/ - Boat Pics |

Posted By: C-Bass

Date Posted: November-30-2009 at 3:37pm

Pete, if you don't mind spilling some more secrets...I'm real interested in the 4x6 wood column and W-beam connection. I know Simpson Strong-tie makes all sorts of connectors for wood to steel beam connections, but most I find are for a wood truss sitting on a steel column. I think the tie-in to the surrounding wall will be pretty straight forward and could be accomplished a number of different ways. And to clear things up a bit, I do plan on having the beam in between the garage doors, this way I won't have to worry about any door clearance issues while something is hanging from the beam. ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: 8122pbrainard

Date Posted: November-30-2009 at 3:53pm

|

Craig,

It really doesn't take that much to secure the W beam to the 4x6. A couple of plates welded to the outside edges of the flanges so you can run a bolt through the top of the 4x6. The W14 in the recommended weight has a 5" flange width so the top of the 4x6 needs to be mortised out a 1/4" on both sides. The walls keep the posts and W beam in their place. However, don't forget the auxiliary cap plates in the eaves if the beam placement interrupts the normal wall cap plates. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Andy

Date Posted: December-05-2009 at 12:55am

|

OK, my new garage. 28'D x 32'W. I am limited by homeowners assn. Floor is 2" high density foam, foil bubble wrap stuff instead of Visqueen. Tubed, 5" slab, extra rebar through out. 2 9x9 OH doors, insulated. Scissor truss roof. 10' walls about 13'6" in the center. Ridge vented. 100a service, no running water. Wired for in ceiling speakers.

Should have done high lift doors. Stuffing R30 in the ceiling, R13 in the walls. Level floor except the last foot by OH doors. Not too sure what Im sheetin the walls with inside yet. I was thinking OSB on all. Covered with FRP in end bay. Planning on a 4 post lift. Pete, watch useing std pex for airline. I run about 150psi and pex has a low burst rating. I'm going to use DOT approved airline. You can find it actually quite easily, and inexpensively. Suicidedoors.com AirBagIt.com and some others. Actually Form and Function would probably have a few other places to recommend as well. What manufacturer are you going with for tankless? I've had real good luck with all of the Takagi installs. Some of which are used solely for space heating, I go annually for maintainence on all. I've used Triangle Tube, Buderus, and Weil McClain condensing boilers as well. I'm putting a Navien in my house this weekend. It has an internal recirc, condensing, and PVC flue. I've only got 3 other Navien installs under my belt, but I like everything I've seen so far. One other system we have been useing lately for additions where slab heating is being added, is the new Taco heat exchanger. It's 2 modulating pumps in a self contained little package. We only use this where we feel they already have the hot water capacity (2 water heaters). Easy to use/install and very clean looking. You could also use an indirect water heater, fed by your boiler. I'll stop now. ------------- http://correctcraftfan.com/diaries/details.asp?ID=3721&sort=&pagenum=6&yrstart=1982&yrend=1982" rel="nofollow - My Blue 82 SOLD! |

Posted By: jbear

Date Posted: December-05-2009 at 3:34am

|

All you guys better start posting some pictures of these palaces...

john ------------- "Loud pipes save lives" AdamT sez "I'm Canadian and a beaver lover myself"... |

Posted By: 8122pbrainard

Date Posted: December-05-2009 at 9:23am

Andy, I just abbreviated the air line tubing to "Pex". What I have chosen isn't the pipe sized type used for water/hydronic but a tube sized rated at 220 psi working pressure. I did spec in a W/M Ultra but am looking at others too. I also what to listen to what the local heating contractors have to say. I think the Ultra has a recirc pump for the primary loop as well. I'll check it out. With the hot water, I haven't really looked at many of the tankless brands very much. I want to hear what the contractors have to say. The side arm HWH indirect is a option I've already put in my spec sheet. For one bathroom it may be more than needed. (It's going in the house addition though!) A efficiency comparison between running the boiler all summer for the hot water and a less efficient on demand would be interesting. The tankless will be within 10' of the lav and directly behind the shower so the circ pump really isn't needed. I'll take a look at the Taco - sounds interesting! Is it for HW or a hydronic zone loop control? Thanks ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: peter1234

Date Posted: December-05-2009 at 9:16pm

|

I have been in the hvac business for 25 yrs at the end of the day simple is better , a weil Mclain boiler and indirect fired water heater will give you years of trouble free service , well water wont effect anything and it is conducive to all types of heating needs. you could try a wall mount unit as has been advised here. but are, or can be trouble in time with wells. also if it breaks in the middle of the nite it is a much safer bet that the service guy will be able to fix the weil Mclain or burnham , or other mainstream product . ------------- former skylark owner now a formula but I cant let this place go |

Posted By: 8122pbrainard

Date Posted: December-05-2009 at 11:53pm

|

Peter,

Thanks for the input. I am on well water and in a bad area as far as high iron content. I do plan on utilizing a premix antifreeze in the hydronic heat system just in case the shop needs to be drained so well water won't affect it. The water supply will be from the house so I can drain/blow back to it's basement. Even though the water is conditioned for iron removal, sounds like what you're saying is it could still be hard on a wall mounted instant tankless domestic hot water system. What happens with them on hard water? Heat exchanger "plate out" with the high delta T? If so, guess I should lean towards the indirect. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 8122pbrainard

Date Posted: February-24-2010 at 2:13pm

|

Well, the qoutes are rolling in for my shop. The BIG shocker is the cost of the closed cell spray foam I had planned on using for a super insulation system. I'm finding the cost is so high that the return on investment may not pay off for 30 years!! Also there is a diminishing return on investment the thicker you go. Comparing blown in R55 and full 2x6 fiberglass R21 in the walls to R28 spray foam wall and R56 ceiling the cost is 5 times over the glass/blown in!! 4 times the cost for spray R42 (less than the R55 blown in) ceiling. I should have known better knowing the high cost of the "pour" foam!! So, I'm back to a R55 blown in cellulous ceiling and 5.5" of glass in the walls but will now beef up the walls with insulating sheathing to about a R26. It's a traditional system but still way up there in R factor. BTW, in dollars, I'm talking roughly 5K traditional to 20K spray foam.

Peter and Andy, Interesting that all the plumbers are stating stay away from "instant" domestic hot water. Problems with scaling even if they run on city water and with well water are a nightmare. With the hydronic heat, they are all saying/quoting indirect 30 gal tanks. The only other logical alternate and avoiding going with a high efficiency power vented gas unit would be electric. I don't want to go there - the electric rates up there are a killer! I'm letting each sub pick the brand of boiler as long as the efficiency is around 94 or better. I figure it's best that each put in one that they are familier with and have had good success with. Two have quoted "Munchkin". I found it interesting that my BTU calculations have been confirmed. 80,000 will do the job and handle the DHW too. Now with all the money I don't spend on the spray foam, I can go with the 300CFM HRV I want!!!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 75 stang

Date Posted: February-24-2010 at 2:26pm

|

There are a couple things i learned about insulation while remodeling my house and turning an old chicken coup into a shop.

We used spray on foam in the house, just a coating to stop drafts etc and then they filled the rest with 6" bats. Very cost effective, warm etc. The company, Momper insulation did it for less than i could buy the bats. in the coup I tried something different and a little cheaper. The standars old gray blow in celulose style they now mix with a binder, fill the cavity and trim off the extra with a spinning paint roller looking devise. Fast, full and cheaper. we cant do either of these in the industrial buildings but it was neat to experiment with the different types. If you can find out who most of the builders in the area used you might be able to afford a little more than you might think. Sean ------------- Take your work seriously, not yourself. http://s133.photobucket.com/albums/q70/Bigblockbandit/Lake%20and%20boats/ - Boat Pics |

Posted By: 8122pbrainard

Date Posted: February-24-2010 at 4:54pm

Sean, I did quite alot of research on insulation (except the spray foam cost!  ) before I even sat down with all the builders. I became familiar with the sprayed on celulose and discussed it with the contractors along with other methods. They all said the same things about it. It's less expensive but due to the binders used to hold it into the wall cavity, it doesn't have as high a R factor as fiberglass. The other thing is the vapor barrier must be extream. Heavy mil. poly and taped at all the seams. If any moisture gets in, the binder fails and it will settle. Now, there's also another method of celulose blow in for walls. A screen type mesh is placed over the cavities and the fill is then blown in. After the cavity is filled, the vapor barrier goes on. This method is also subject to settling over time. ) before I even sat down with all the builders. I became familiar with the sprayed on celulose and discussed it with the contractors along with other methods. They all said the same things about it. It's less expensive but due to the binders used to hold it into the wall cavity, it doesn't have as high a R factor as fiberglass. The other thing is the vapor barrier must be extream. Heavy mil. poly and taped at all the seams. If any moisture gets in, the binder fails and it will settle. Now, there's also another method of celulose blow in for walls. A screen type mesh is placed over the cavities and the fill is then blown in. After the cavity is filled, the vapor barrier goes on. This method is also subject to settling over time.

I had really hoped for the spray foam but the cost kicks it out for a option. My hope now is the fiberglass is installed with the utmost care. There are always gaps plus obstacles like electric boxes are a PITA. Insulating sheathing makes up for some of the issues! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 62 wood

Date Posted: February-24-2010 at 6:28pm

|

Pete,

Agreed , fiberglass insulation is probably most cost affective...but installation is the key. I always do mine myself, no one else to blame that way. Ive seen too many jobs where a guy is just pushing the insulatuion between studs with no regard to "fluffing' it up for the max R value, or making sure it even fits the opening correctly. Another thing...dont forget to caulk,or otherwise seal any of the holes where wiring is drilled thru plates into an unheated area,...ie attic, etc. I have also cut 1" (or what ever thickness is needed to fill the area) blue or pink styrofoam blocks and glue to the walls immediately behind electrical boxes on exterior walls. AND lastly dont forget....CABINETS...LOTS of CABINETS!

. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1117&sort=&pagenum=6" rel="nofollow - 64 American Skier 62 Classic.. 73 Ski Nautique |

Posted By: 8122pbrainard

Date Posted: February-24-2010 at 10:13pm

Steve, You saw the cabinets in the plans - Uppers, base and talls taking up 192 sq. ft. of wall space! Not enough? Should I fill the opposite wall up too? I know the cabinet business is on the slow side - are you trying to get some more business?  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 62 wood

Date Posted: February-25-2010 at 12:27am

|

Pete,

Was it that obvious?

Actually, I think your original plans will probably do just fine! ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1117&sort=&pagenum=6" rel="nofollow - 64 American Skier 62 Classic.. 73 Ski Nautique |

Posted By: Waterdog

Date Posted: February-25-2010 at 9:36am

|

That spray can foam is conductive while it's still "wet" I found out by suprise ! ------------- - waterdog - http://www.correctcraftfan.com/diaries/details.asp?ID=3896&sort=&pagenum=2&yrstart=1978&yrend=1978" rel="nofollow - 78 Ski Tique |

Posted By: 8122pbrainard

Date Posted: March-31-2010 at 6:16pm

The contract was let out Sunday. This step number one was yesterday!!

And, the contrator does have the correct set of prints!!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: C-Bass

Date Posted: March-31-2010 at 6:37pm

|

Sweet, keep us updated, Pete.

I'm actually filing for the building permit on mine this week. It's going to be more basic (used 99% just for storage), and unfortunately mine isn't located near water, but I'm still excited for the extra space. ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: 8122pbrainard

Date Posted: March-31-2010 at 8:20pm

|

Craig,

My general will be going in for the permit for me which is great as I really don't want to drive 300 miles to deal with the bureaucracy plus he's got all the connections!! This one will be the easy one as well. No UBC requirements and no UBC inspection process. All the county wants is a plot plan showing the location and a floor plan showing the size. They didn't even want the current survey!! They said the one (20 years old because they are a "little" behind on updating their records) on file is good enough! When I get to the house addition then it may be a different story?? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: emccallum

Date Posted: March-31-2010 at 8:35pm

| Since your GC has the connections, get him to slip in a home addition permit while he is there! |

Posted By: 8122pbrainard

Date Posted: March-31-2010 at 9:51pm

|

Craig,

The one important thing I forgot that the county does want is their permit fee!! What did you end up doing about the W beam for lifting? Ernest, I wish he could slip it in for the house but the permit is only good for 2 years. I don't know if I'll be ready by then but I do need to address it soon. The county will be adopting a not to exceed 30% permeable rule in about 2 years. Not knowing if they will consider my gravel drive and septic field non permeable or not, I may be over the limit. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: jbear

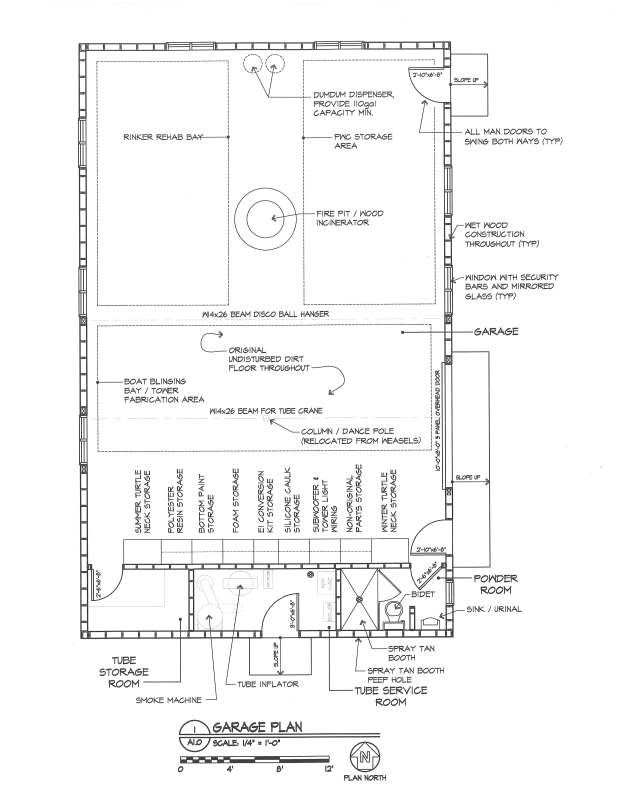

Date Posted: April-01-2010 at 2:35am

FINALLY a picture. We better be seeing some more. By "correct" plans you do mean the ones with all the cool stuff quinner added for you..right? john BTW: Very nice to talk to ya a couple nights ago. ------------- "Loud pipes save lives" AdamT sez "I'm Canadian and a beaver lover myself"... |

Posted By: quinner

Date Posted: April-01-2010 at 2:49am

Pete, your Garage is going to be Wicked Cool!! ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1143" rel="nofollow - Mi Bowt |

Posted By: jbear

Date Posted: April-01-2010 at 2:52am

|

Now THATS what I'm talking about!!!

john ------------- "Loud pipes save lives" AdamT sez "I'm Canadian and a beaver lover myself"... |

Posted By: C-Bass

Date Posted: April-01-2010 at 5:40pm

|

Pete,

I'm going to go with a W1426 eventually. I say that because while I would prefer to put it in right away, for obvious reasons, the budget is who I answer to. I have thought long and hard about getting it placed in there after the garage is built and I'm pretty confident it can happen. You're lucky on the permit process. I'm going to have $500 wrapped up in fees before I even move any dirt! The permit fee itself ($50 + 0.05/sq.ft.), plus my permit requires a certified site plan by a surveyor ($300), and a health department inspection to make sure that I'm not building over my septic system ($50). All of this so they can make sure and increase my property taxes...  ------------- Craig 67 SN 73 SN http://www.correctcraftfan.com/diaries/details.asp?ID=6103" rel="nofollow - 99 Sport 85SN |

Posted By: Hollywood

Date Posted: April-01-2010 at 5:55pm

------------- |

Posted By: Waldo

Date Posted: April-02-2010 at 5:56pm

|

Nothing gets by Hollywood. LOL.

Waldo |

Posted By: 8122pbrainard

Date Posted: May-24-2010 at 8:57pm

|

With construction projects there always seems to be problems especially when you're not around to keep a eye on things. I got a phone call from my neighbor up there today (a Milwaukee resident). He wasn't too happy to say the least. Over Christmas I had cleared the project with him regarding the concrete pour 5' from his property line. The contractor had informed me that the concrete trucks shoots would be able to reach that wall leaving only about 10' in the middle. This 10' they would haul in with the Bobcat bucket. Well that's not what happened. They drove the concrete truck out onto my neighbors yard. Not only did they do that but they drove the trucks up his driveway and then out onto his yard!! I'll know more when I get up there Thursday but evidently there are some rather deep ruts plus possible damage to a French drain for the neighbors garage floor drains.

At least the footings and foundation walls are poured!  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: emccallum

Date Posted: May-25-2010 at 11:16am

|

Well, I am glad to hear we aren't the only ones with crazy concrete truck drivers! I was pouring some footers and had it all planned out where to enter and exit. Even flagged the route. Not only did they destroy my yard, crack the driveway, but took off up the driveway with the chute open and concrete spilling out! To top if off, I called the company and his first comment was "We are only repsonsible for damage up to the time we leave the main road." Well, after a couple of more phone calls, they were at the house pressure washing the driveway, and filling in the ruts. I think they do it on purpose!

I think a case of beer for the neighbor may be in order. |

81nautique wrote:

81nautique wrote: