A little different Stroker build |

Post Reply

|

Page 123> |

| Author | |

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: A little different Stroker build Topic: A little different Stroker buildPosted: January-23-2012 at 1:44am |

|

Hey guys, How the hell are you? I know it's been a while since I've been on here but I wanted to share what I've been doing the last few years. Yeah, three years almost to the month since I started a new project. You'd think it was a friggin' 55 Hurricane project for God's sake!!!! Right Allen??? By the way, that Hurricane is nothing short of amazing!!!!

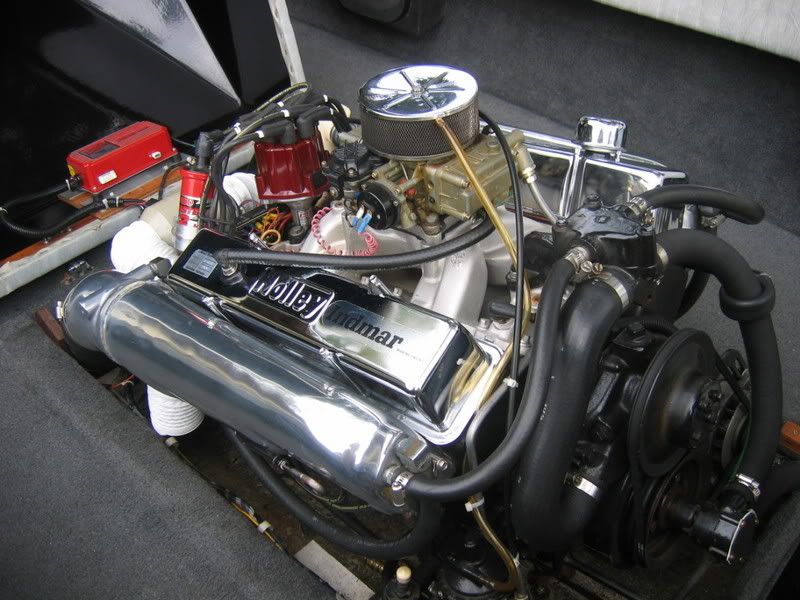

Anyway, what have I been doing the last three years? Well, that's a bit of a story. As Tim might say, grab your favorite adult beverage, get comfortable and enjoy a read. By the way Tim, cudo's to you too for that BFN project. That's absolutely awesome!!!! I have been able to lurk for a couple months off and on here but as you'll learn, my time has been somewhat limited. I have noticed that there are a lot more new members since I was last active here so maybe a little background is in order. Hell, after three years, a little background is in order for everybody! So why is this being posted in the Off Topic section? Well for those of you not in the know, I don't own a CC. It's an '86 American Skier with a SBC. So I wanted to be politically correct. For a little refresher, here is what I started with.

Back around feb. of '09, Hollywood was down here for some skiing and I had some of my wife's family down here too. John (JBear) and I had both our boats out for everyone to enjoy some water time on our chain. Her nephew was pulling me on a nice long footin' run and when I dropped off, I heard this real bad knocking sound coming from the boat. I could hear it from 100' away while I was floating in the water. It was one of those sounds that makes your heart sink. The oil pressure and temp were all good so I told him to keep it running. It was coming from the bottom end and was consistant with crank rotation. It definitely wasn't valve train. It wasn't missing or idling rough either. Except for the knock, everything felt and looked perfectly normal. So after idling for a couple minutes, the knock mysteriously vanished. I shut it off and turned it back on several times and it still sounded perfect. The oil was topped off with no signs of water in it. We ran it back to the trailer and loaded it up. The next day, I changed the oil and fired it up in the driveway and again, everything was normal. I took it to the lake the next weekend and as soon as I fired it up, the knock was back. It was now time to tear into it and see what was going on. Ever since I've had my baby, I always said that whenever it came time to rebuild, I wanted to stroke it to 383. So with 1300 hrs I figured it was the perfect time to do that right? Unfortunately, two weeks later, I had to take almost a 20% pay cut to keep my job, but hey, I still had a job and insurance. We were still OK for paying the bills but there was nothing extra for building a stroker. I quickly realized, there was no way that I was going to be able to do much of anything without some help, so I got a second job bartending. So now I'm starting to save some money for my new project and I also start researching what I really want to do to it. Now keep in mind that I know enough about engines to be dangerous. I've ported heads and changed them out as well as intakes and distributors, but I've never attempted anything like this. I have learned a lot from this forum but until you actually do something like this, you never really understand what's involved. I knew that I was in for a real learning experience but at the same time I was determined to do this myself. I started reading books, articles, websites and pretty much everything else I could get my hands on. I had pretty much all the tools I needed but I was still going to have to acquire some specialty items that I didn't have. Things like an engine stand, blast cabinet, a hoist of some sort. I would also need some specialty tools like a tapered ring compressor, degree wheel and several different precision measuring tools just to name a few. As you have probably figured out by now, this was going to be a marathon and not a sprint. Stay tuned guys. I promise it starts getting interesting now. |

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

jbear

Grand Poobah

Joined: January-21-2005 Location: Lake Wales FL. Status: Offline Points: 8193 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 2:39am Posted: January-23-2012 at 2:39am |

|

boy...I can't wait to see how this turns out!

john |

|

|

"Loud pipes save lives"

AdamT sez "I'm Canadian and a beaver lover myself"... |

|

|

|

PAPA

Senior Member

Joined: October-06-2009 Location: Fremont, In Status: Offline Points: 202 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 9:50am Posted: January-23-2012 at 9:50am |

|

Boat looks really nice; sounds like its going to be a fun build.

|

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 10:13am Posted: January-23-2012 at 10:13am |

|

now, this will be interesting lol

quit dangling |

|

|

"the things you own will start to own you"

|

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21210 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 11:05am Posted: January-23-2012 at 11:05am |

|

Eddie, great to have you back! Ive been hearing rumors about this fire breathing 383... cant wait to hear more.

|

|

|

|

Kristof

Grand Poobah

Joined: October-08-2007 Location: Bree, Belgium Status: Offline Points: 3412 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 11:42am Posted: January-23-2012 at 11:42am |

|

Hi Eddie,

It's been a long time!! "Email Notify me of Replies" is turned on

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 12:08pm Posted: January-23-2012 at 12:08pm |

|

Eddie,

It's good to hear from you. Keep us posted as to what you find and your progress. Are you going to let John near that engine? If so, make sure he just hands you the tools!

|

|

|

|

storm34

Grand Poobah

Joined: November-03-2008 Location: Dexter Iowa Status: Offline Points: 4496 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 1:27pm Posted: January-23-2012 at 1:27pm |

|

Beautiful Boat.

Signing up as well. |

|

|

|

81nautique

Grand Poobah

Joined: September-03-2005 Location: Big Rock, Il Status: Offline Points: 5817 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-23-2012 at 9:35pm Posted: January-23-2012 at 9:35pm |

|

Hey Eddie good to see you back. I only have 2 years to go on the Hurricane, I may still beat you! Get a move on LOL.

That is an awesome boat and one of my favorite Non Correct Crafts. |

|

|

You can’t change the wind but you can adjust your sails

|

|

|

|

boat dr

Grand Poobah

Joined: June-27-2004 Location: United States Status: Offline Points: 4245 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 1:11am Posted: January-24-2012 at 1:11am |

|

Eddie, that is too cool buddy, cant wait to see you and the bear man in March.

|

|

|

|

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 1:44am Posted: January-24-2012 at 1:44am |

|

Ditto the Doctor Eddie. It was an honor being the "official" Jbear and Eddie SJRR tow boat last year,maybe we can have a test ride this year

|

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 2:09am Posted: January-24-2012 at 2:09am |

|

Sorry guys. I'm back for a little more to tempt your taste buds.

I remembered a while back a thread about redneck engine hoists. I figured that I needed to add my own version to that. I knew that I needed a lift but I didn't want one that would take up more floor space. I knew that a cherry picker has it's limitations for getting a motor over the gunnel. I live in a quiet neighborhood and just couldn't be hanging an engine from a tree with a block and tackle. So I had to put my redneck engineering skills to work and figure out an alternative. If I was going to be building a motor in my garage, I also needed better lighting. A lot of it. I'm not getting any younger you know and the lookers are getting tougher to do my cypherin' without good light. This is what I came up with: This has the lights on.

The I-beam spans the whole width of my garage. I just happened to get really close color matching with some rustoleum spray paint from Lowes.

The free trolley that I acquired after some sandblasting and a coat of paint as well as the Habor Freight chain hoist.

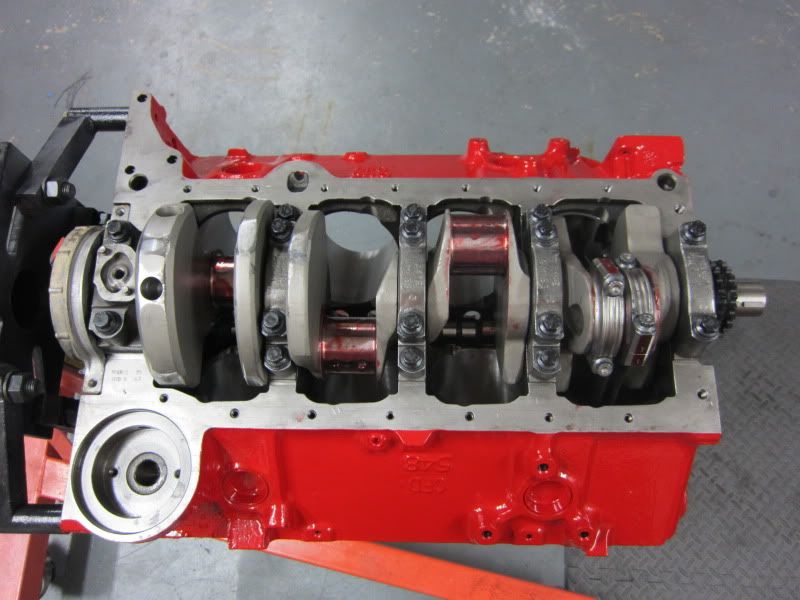

I found out that I have 2x8 joists in the garage ceiling. The centerline of one joist is directly above the centerline of the I-beam. I figured that a single joist wouldn't be very sturdy so I had three seperate three foot pieces of I-beam cut. I have them set at 90 degrees to the main beam and resting on top of the joists in the attic so they span across three joists with the center of the three the one that the main beam is mounted under. I cut holes in the top flange of the main beam and the bottom flange of the cross beams and bolted them together with 3/4" threaded rod. My thinking is that the main beam being attached along the bottom of a single joist would spread the load along that whole length of joist instead of straining it from a single point. Then the cross pieces additionally spread load to the joist on each side of the main from above. I know it's probably very confusing to envision. I would've done a very cool CAD drawing like Tim did with his BFN project to clarify this but I'm just not that knowledgable or have the time. Sorry. Either way, I was expecting to get all kinds of creaking, cracking and popping from the joist when I first put some weight on it. I didn't hear even a whisper of spraining on the joists. The trolley also works perfectly. I can raise the engine, roll it over and mount it to the stand or drop it into the back of my pickup without breaking a sweat. It also worked awesome for just holding up the back end of John's motor while we pulled the tranny out to get rebuilt. It turned out better than I ever expected. A really nice start to the project. Harbor Freight and Wholesale Tool were my best friends during this project. I also found some really good deals on Ebay for some of my special needs. I finally have the pieces in place to tear the engine out and start disassembly. I've been working my ass off for a year now and getting my engine fund built up after numerous setbacks like tires and brakes for both of my vehicles, a new sand filter for my pool, and the numerous tools as well as the above mentioned hoist and lighting that I figured I would need for the project. It also gave me the time to do my reasearch for the parts and pieces that would be going into this beast. So let's get into this!!!! After I bought my baby way back in '92 I knew that this motor was pretty hot for the day. I contacted Indmar and the tech that I talked to there told me that the engine was advertised at 290HP but in reality, it was every bit 300 ponies. Indmar only made about 50 of these bad boys a year for a four or five year run in the mid to late eighties. I know that you guys are sharp when it come to this cool stuff so you know that a typical SB (Ford or Chevy) in the '86 time frame was running 245-260HP. A few options might have been running up to the 285HP range. This was, to my knowledge probably the hottest factory optional SB a person could get in that era and really didn't get challenged until the GT-40 burst upon the scene in '93 if I remember right. I must say that this engine did always run really well. I completely enjoyed every minute listening to that thing purr. I guess you really don't know what you have until you tear it down though. The numerous books I read up on confirmed the horror stories of guys who purchased what they thought were 500HP crate motors. After they were installed and hooked up to a chassis dyno, they find out that monster 500HP motor is actually 350HP at the wheels and in reality maybe a true 400-425HP motor. When I tore this thing down, I found out it really was well put together. I have no doubts now that it probably was what they said it was. 4 bolt mains, forged crank, windage tray, double roller timing chain with iron gears and a 650CFM carb. Add in the very cool aluminum exhaust manifolds and you have a pretty hot ticket by today's standards, let alone 1986! The timing gears and chain had virtually no wear on them. You guys also know that you just don't get a forged crank in any motor. After seeing this you can't imagine how tempted I was to just bore it 30 over and turn this thing into a very hot 355CI for some very reasonable scratch. So what the F**K went wrong???? Well, as I was tearing it down, I spun the rotating assembly and I couldn't find any indication of a problem. There was no binding, banging, tight spots or anything to indicate a problem. The bearings looked good to me but I really didn't know what I was looking for either. Number 4 main bearings had a blueish tint to them indicating things were getting a little hot. Some minor scratches in a couple bearings indicated some foreign matter of some sort but the oil pan had absolutely no shavings of any kind in it. I finally got the crank and pistons removed and I found this:

Yup, that's number 6 piston and rod. It has good movement until you get out to the outer limits of the pin/rod range of movement and then it tightens up like this. Number 6 is attached to the same main bearing that was tinted blue. Guess I found the problem. The piston skirt had to be slapping the *************** out of the cylinder. What I don't understand is how or why it happened. Any speculation from those of you who know better, I'm all ears. By the way, all of the cylinders were within a few ten thousenths of each other except number 6. That one was a few more ten thousenths larger but it was really nothing serious at all. So, now I need a machinist. That was a chore in itself. After you get a little knowledge and get an idea what you want to accomplish, a 30 second conversation on the phone with a perspective machinst to trust with your motor will tell you if you hit paydirt or Billy Bob's small engine repair shop. That took me about a month to find one that I felt comfortable with. Mike Ford Racing Engines just outside of Orlando. He wasn't very quick but I didn't need him to be and he was probably a little more expensive than some others but he is good. There is no doubt in my mind. I wouldn't hesitate to use him again. He also confirmed that the number 4 bearing had gotten warm but the block was in real good shape. He also checked over the stock crank to see if that was in good shape and reusable. It was. He asked if I wanted to sell it to him but I have a feeling I could use that in the future???? You think???? So here are some of the goodies that I was putting in. Old vs. New

6 of the 8 jugs

I decided on a Eagle forged crank. After all why would I go backerds to a cast crank when I have a forged crank in there to start with? I also went with 6" H-Beam rods and Mahle forged pistons. The whole rotating assembly according to Eagle is rated for 750HP. Probably overkill for this application but I wanted a strong bottom end. If I ever decide to bolt on some extra options in the future, I know the bottom end is stout enough to handle about anything I throw at it. I had a hard time determining Eagle, Scat or is there anything else I should be looking at. All my research said that it was really toss up between the two. My next option was going another $700-$1000 for a entry level Callies which just wasn't happening. I heard good and bad about both Eagle and Scat so I went with recommendations from trusted friends who had experience. I have absolutely no problems with my decision. I wouldn't hesitate to do it again. In '86 Chevy changed the RMS on the SB to a one piece unit. That change also mandated a change in the adapter on the flywheel flange that made it go from internal balance to external. I really wanted to keep it internal balance if at all possible. If I ever wanted to change the damper or the flywheel for whatever reason, I wanted to be able to just bolt it on instead of pulling out the entire rotating assembly to get balanced. Eagles documentation said that it could be balanced internally. Scat's ionformation said external ONLY. That was my final decision maker right there. My machinist was a little scheptical that it would be able to be done. With standard I-beam rods, no problem, but with 6" H-Beam rods he might be required to drill out the counerweights and add heavy metal to balance it internally. A very expensive operation. He was surprised that the assembly balanced. He said if it wasn't for the lighter Mahle pistons, he wouldn't have been able to do it. So now all he had to do was Zero balance my stock flywheel and I put a zero balance 8" Professional Products damper on the front end. We're on a roll now. You guys can chew on that a while. More to come. |

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

jbear

Grand Poobah

Joined: January-21-2005 Location: Lake Wales FL. Status: Offline Points: 8193 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 2:54am Posted: January-24-2012 at 2:54am |

|

Pete..I get to stand close by and watch.

And guys..the pictures do not do justice to how slick the hoist is. There is more planning and work in the hoist and lighting than most guys wanna do. Add in a big compressor and a sand-blast machine..plus a full size refridgerator and we are talkin' sweet. Well I ain't stealing any more of backfoot's thunder....but can add that this has been pretty fun to watch! john |

|

|

"Loud pipes save lives"

AdamT sez "I'm Canadian and a beaver lover myself"... |

|

|

|

Kristof

Grand Poobah

Joined: October-08-2007 Location: Bree, Belgium Status: Offline Points: 3412 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 8:54am Posted: January-24-2012 at 8:54am |

|

Eddie, that was a treat to read!

Well written and elaborate. Made my coffee taste even better

Boy, would I love to have a garage like that. And the hoist is magnificent, nothing Redneck about it! |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 9:22am Posted: January-24-2012 at 9:22am |

|

foreplay..........get to the insertion lol

nice read Eddie |

|

|

"the things you own will start to own you"

|

|

|

|

Riley

Grand Poobah

Joined: January-19-2004 Location: Portland, ME Status: Offline Points: 7966 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 11:44am Posted: January-24-2012 at 11:44am |

|

Great thread! What's the height of your garage walls?

|

|

|

|

JoeinNY

Grand Poobah

Joined: October-19-2005 Location: United States Status: Offline Points: 5698 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 1:39pm Posted: January-24-2012 at 1:39pm |

|

Looks like fun so far, but I also call foul on the use of the term "redneck engine hoist" in this thread...

|

|

|

|

Randy_in_Ohio

Platinum Member

Joined: September-13-2006 Location: N. Canton, OH. Status: Offline Points: 1891 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 5:39pm Posted: January-24-2012 at 5:39pm |

|

Good to see you back on here Eddie. I have to agree, that is one of the nicest non-CC boats I've seen on here. That hoist is impressive. I like the way you have your boards/skis hanging from the ceiling too. What did you use, besides the obvious pipe insulation, to do that?

This should be a fun thread to watch

|

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 7:04pm Posted: January-24-2012 at 7:04pm |

|

I think it was in the organiizers section of Lowes. I'm sure that Home Depot would ahve them too. They're just wire hangers for organizers that you hang on the wall or the from the ceiling. The hangers are 90 degree turns on them so I just got some flat stock splice kits that included the screws in the hardware section of Lowes and used them as a strap to over the wire hangers. Then I just wrapped some foam insulation over it. Works out really slick. Space is at a premium in my garage so I have to do what I have to do. You don't see it in the pics but I have two 8x8 wire racks of the same material right above each of my garage doors for storage. They were a real pain in the butt to hang but work out really nice. Moving down here without basements really made me have to use the all the space I can find as efficiently as possible.

|

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 7:13pm Posted: January-24-2012 at 7:13pm |

|

Thanks all for the words of assurance and praise. I just wanted to get you guys up to date so I can continue to move forward. I'm still not done at this point but it's definitely looking pretty good.

Good stuff coming up tonight once I get home. Stay tuned. |

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

86BFN

Gold Member

Joined: July-28-2008 Location: Indiana Status: Offline Points: 882 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 9:32pm Posted: January-24-2012 at 9:32pm |

|

Good stuff indeed. I checked the notify box as well. BTW, is this a lefty or righty? sorry if I missed it. I was speed reading. My Dyne has about 1000 hrs on her so I'll be watching this thread with great interest.

Welcome Back and try not to leave us hanging too long... Steve |

|

|

|

boat dr

Grand Poobah

Joined: June-27-2004 Location: United States Status: Offline Points: 4245 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 9:41pm Posted: January-24-2012 at 9:41pm |

I beg to differ there old wise one, We do indeed have basements in the deep south, but we call them "cement ponds"    Cool shop too..... Cool shop too.....

|

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-24-2012 at 9:49pm Posted: January-24-2012 at 9:49pm |

I had to measure them. 8.5'. The I-beam is 6". |

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

Morfoot

Grand Poobah

Joined: February-06-2004 Location: South Lanier Status: Offline Points: 5335 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 1:12am Posted: January-25-2012 at 1:12am |

John I hope that maybe your hanging out with Eddie a little bit more than just on Sat mornings for your Barefoot runs. He might be able to teach you a thing or two and might be able to use an extra hand or two to hand him a tool but only as long as you stay away from sharp pointy ones.

Eddie, looking forward to the thread updates. I think it's safe to say you won't get chased off the site because you don't own a "real" boat.  We'll grandfather you in. Looking forward to catching up with you and the bear in a few weeks. Glad to see you poking your head out from under rock you've been hiding under. We'll grandfather you in. Looking forward to catching up with you and the bear in a few weeks. Glad to see you poking your head out from under rock you've been hiding under.

|

|

|

"Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman"

|

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 4:16am Posted: January-25-2012 at 4:16am |

|

Well where were we. Oh yeah, I was about to tell you about the heads. I decided to go with iron instead of aluminum. I just feel that the aluminum haven't had a chance to prove their longevity over good old iron. Joe and a few others are already in the process of that.

I chose RHS Pro Action with 72CC chambers and 200CC runners. I did a home pocket port and gasket match on the intake and exhaust sides. Then I polished the chamber roof of each cylinder. I figure that I have about 30 hrs. with die grinder working on those things. It's not hard as long as you have the tools but it is very time consuming. After that I had to take them back to Mike so he could shave off a few thousanths to fix my "oops". You will always have a oops or two when you do this. The Eagle catalog says that with my rod/piston combination and 76CC chambers you should have 9.7:1 compression assumming a .040" headgasket. With the smaller 72CC chambers and the fact that Mike had to shave .010" off the deck to true that up and that the heads were cut .003" this should be at 10:1 or even a little higher. That's right where I wanted it. I didn't actually CC the chambers to verify but it has to be close. I had some really nice pics showing the different stages of the porting but our camera fell in a puddle and we lost them before I could download. Bummer. So here is the crank and block. Notice how the edges of the block were machined out for the crank to clear the block. The oil pan needs to be able to do that same thing.

Now for the cam. This is a standard rotation engine so I wasn't limited by some of the same issues you guys get into. I decided to retrofit this to hydraulic roller lifters and cam. Being my first real build, I decided that I wouldn't try and get a custom grind. I figured that there were probably thousands of hours of R&D and testing on about any engine combination you could think of so there had to a pretty good cam in someones catalog already. My research told me that I should probably be looking for something in the 270 degree duration range and 110 to 112 Lobe Separation Angle (LSA). The problem I had is that there really isn't a lot of documentation on selecting a marine cam so I had to make some educated guesses. In most applications, anything over 270 duration can start to have drivability issues. The peak torgue RPM generally starts to rise farther up the RPM band. A wider LSA will give a wider power band but you have lower overall peak HP numbers. A stock or aftermarket exhaust is also a pretty important factor in the cam you can get. I was planning on reusing my aluminum manifolds. I decided to go with a Comp cam because they had the best information on their marine specific grinds. They had a 270 that they stated was the biggest one recommended for a stock exhaust. Now what was their definition of a stock exhaust? A fairly constricting Merc or Volvo outdrive or a below the waterline open exhaust with a high performance aluminum manifold? The next one was a 276 that was recommended for jets and open exhaust? One thing that was consistant in several books that I read is that there are two common mistakes made by engine builders: 1) Too much cam 2) Too much carb It is agreed by virtually everybody that to err on the small side is much better than the other way around. So my cam specs are as follows: Int. 270 degrees duration @.006" and 218 degrees @.050" 495 lift Exh. 276 degrees duration @.006" and 224 degrees @.050" 503 lift 1500-5500 RPM range 112 LSA I decide to stick with Comp for the entire valve train. Roller lifters, Magnum pushrods and Ultra Pro Magnum roller rockers. Everything fit really nice.

Gotta cut this short again. I had issues tonight losing data twice. |

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

jbear

Grand Poobah

Joined: January-21-2005 Location: Lake Wales FL. Status: Offline Points: 8193 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 4:45am Posted: January-25-2012 at 4:45am |

|

stayed up late just to read tonights episode..altho I understand exactly none of this...

but I know it is gonna be a treat for you guys to see the finished product. did I mention that its loud and fast...that much I understand. backfoot..a very interesting friend indeed. john |

|

|

"Loud pipes save lives"

AdamT sez "I'm Canadian and a beaver lover myself"... |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 10:17am Posted: January-25-2012 at 10:17am |

|

well i learned one thing so far, the no basement thing.....now i know why y all set up on the front porch

coming along nicely eddie |

|

|

"the things you own will start to own you"

|

|

|

|

86BFN

Gold Member

Joined: July-28-2008 Location: Indiana Status: Offline Points: 882 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 3:17pm Posted: January-25-2012 at 3:17pm |

|

make sure you get some good pictures of the heads before you install them. Ya'll know how we love pictures.

|

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 9:41pm Posted: January-25-2012 at 9:41pm |

|

Last night I was excited to get you guys up to speed and just as I was getting ready to post, I messed up something and lost everything I had done for the last two hours. Then I did it a second time two hours later. Somethings this tech stuff gets to me.

On to the induction. I had installed an Edelbrock Performer Air Gap on my engine over 10 years ago and loved it. I was planning on reusing that but numerous people told me that a Stroker likes to breathe…a lot!!! So I upgraded to an RPM Air Gap. For the carb I know that Eric wants to see at least a 780 on this thing. Well, there is actually a mathematical formula for determining proper carb size. All you have to do is know the CID and how many RPM you want to run. A 383 running at 5500 RPM can only inhale 609CFM if my memory serves me right. My 650CFM carb should be more than sufficient for this application. I called Holley to verify and they also concurred. I asked the tech about any jet change recommendations and he said I shouldn’t need any which surprised me. If the carb was properly jetted for the 350, having it bolted to a 383 is only allowing more air through it which in turn will deliver more fuel based on the air demand. You shouldn’t have to change jets just because it’s going on a bigger motor. It actually makes some sense when you think about it. I just never though about it in that way. I’m still gonna do some plug chops to make sure. I did rebuild the carb before I put it back together. Back down on the bottom end. The stock oil pan has a center drain on it with an EZ Drain adapter on it. That adapter happened to sit directly above one of the thru-hull studs from one of the tracking fins. I literally had .019” clearance between them since I’ve owned the boat. I checked the clearance with a feeler gauge every oil change to make sure everything was OK. That was always a little too close for my comfort so I wanted to change it now. In fact, when I removed the pan I found out that it was actually dented in from the adapter hitting that stud. I took a pic of it but it really doesn’t show the dent very well at all with the pan painted black. I found a Milodon oil pan that had a side drain and was supposed to clear Stroker cranks. Remember that the inside edge of the block is machined out for Stroker crank clearance (check the pic of the crank sitting in the block earlier). The oil pan needs to also clear that crank. This Milodon pan fits nicely and it also contains a built in windage tray. It’s a five qt. pan where the stock pan is six but I’ll still have 6 qts. with the filter. If you look close, you might be able to see that the adapter in the old pan is pushed in a little bit. At least you see the difference between the two pans. I did end up using the EZ Drain on the new pan.

It was really difficult finding a pan. You wouldn’t think it would be a big deal. Most Stroker pans I found were 7 qt. capacity and deeper than my stock pan so I was concerned about it fitting based on the clearance issues I had. I found out that American Skier purposely tried to keep their engines mounted as close to the keel as possible to maintain a lower center of gravity (CG). It also keeps the angle of the prop shaft down (or would that technically be a higher prop shaft angle?). Their thinking I believe was lower CG + lower prop shaft angle (or higher???) means improved performance? Who knows. It would take an entire engineering department and some very detailed testing to really prove it either way. I’m sure that Tim and Joe will have spirited conversations about my theories. LOL.!!! The tranny and bell housing have a little less than a ½” clearance to the bottom of the bilge. My throttle cable runs underneath the engine and up to the carb from the back of the engine and it rubs in a couple places when sliding it around underneath the motor. That’s not a lot of room. Now what about the oil pump? Standard volume, standard pressure is all that’s needed. A Milodon pickup would be properly fitted to their own pan so it only made sense to use a Milodon pump also. The nice thing about the Milodon pump is that the pickup has a tab on it that screws into the pump to make sure that the pickup doesn’t work itself out. It’s recommended that pickups be installed and then brazed to the pump body so they can’t work loose during operation. How bad do you think that would be to be running at 5K RPM and have the oil pickup tube drop out of the pump????? This Milodon unit just needed a couple drops of locktite and a screw installed for a much easier solution. Be back tonight yet. |

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

backfoot100

Platinum Member

Joined: January-03-2007 Location: United States Status: Offline Points: 1897 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-25-2012 at 10:28pm Posted: January-25-2012 at 10:28pm |

|

This project is coming along pretty good. Slow, but pretty good and I decide that I want to polish my manifolds the way that they should have been polished originally. Years ago I just polished the areas that I could really get to without disassembly. I wanted to remove the elbows and polish them like they should be. Might as well do it now right??? I never had any leaks in them but I thought that the elbow gaskets were 25 years old now and they won’t last forever so replace them while I have the chance and they should be good for my remaining time on this planet. You guys know what my manifolds look like. They are really the pride and joy of everything that engine represents to me. I’ve never seen a set like them before and I would sacrifice additional performance to keep them.

Pete, stop crying like a proud papa…LOL. Don’t think for one second this a “keep it original” thing. This build is far from that. This is sort of a hot rod…gear head….Katy bar the door….hide the women and children…sort of thing with high tech modern parts while keeping an old school retro flair. Cool S**T. I have to admit that I was scared as hell to do this to the manifolds. I remove the four nuts and crack the first elbow and now there’s no turning back. I’m committed. All four nuts on each manifold came off easily and all four studs on each manifold are in really nice shape. I still need to remove the studs so I can face the ends of the logs properly before reassembly. I remove the first stud no problem. Then immediately snap off the next two studs in the first manifold. I didn’t try anything on the last one. OK, no big deal. Get out the EZ Out and promptly snap that thing off. Oh crap. So I don’t touch the other manifold at all which has all four studs intact. I take them to my machinist and explain what I’m trying to do and he says that he should be able to get them out with a little persuasion. After three weeks, he snaps off another EZ Out in one and he’s only able to remove two more. So I have three out of eight removed and two EZ Outs in the five remaining that are all snapped off at this point. I’m doing a lot of praying now. I even have John saying a few things to help the cause. How bad is that to be praying for a couple manifolds????? So my machinist tells me about a place in Orlando that has some high tech machine that can still remove these with electrical current and water. I have since talked to others about it they knew exactly what I was talking about. I’m sure Pete knows what it is and can elaborate more. Anyway it has been a few years and he didn’t know if they were even in business anymore. He tried calling them, and they were still open and he explained what was happening and they say sure, bring ‘em over. They end up being able to get them out but they destroyed the threads doing it which normally doesn’t happen. They put heli-coils in and everything is good to go. Needless to say I’m very relieved and will never take them apart again. Ever. Never. Ever Again. WHEW! That even made me start sweating recalling that trauma. So now, I can start polishing these things. If you look way back at the pics of the original motor, you might see that the manifolds have a few waves to them. I end up filing and using some of my porting abrasives to smooth out these high spots, then sanding with 60, 120, 200 and 400 paper before I can start buffing out the metal with some of Eastwood’s buffing compounds and wheels. They look much better now that I got into the crevasses where they bolt together and removed some deep scratches that were always in them. I figure that I put somewhere between 40 and 50 hrs into them. I know that you guys have to be really tired of all this reading but grab a few more beers. I test fit the manifolds to the heads and realize that the manifolds come out from the head and immediately turn up. It’s so quick that they hit the valve cover flange on the heads. Evidently the RHS heads have a bit taller valve cover flange area to help prevent leaking and the manifolds will never fit like this. I figure that I can find some spacers of some sort to put between the heads and the manifolds. I end up finding a set of 3/8” header flanges from a place online for like $30 each. I need another set of exhaust gaskets now too. The flange and both gaskets give me an extra ½” spacing from the head to the manifold but now I have a little bit more port matching to do. You can see in the pics what the flanges and exhaust manifold ports look like before and after the porting. This is exactly the same principle used on the heads that I can't find the pics of. You can see this makes a huge difference in letting the engine breathe more efficiently. Here's the spacer that I ended up with. You can see the sharp edges of the manifold ports.

Close up of the sharp edges before porting. Exhaust gases hitting this would be like hitting a brick wall.

After porting. Nice smooth edges for the gases to escape.

More after porting

|

|

|

When people run down to the lake to see what's making that noise, you've succeeded.

Eddie |

|

|

|

Post Reply

|

Page 123> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |