Prop Nut and Cotter Pin Replacement |

Post Reply

|

| Author | ||

Otto Throttle

Senior Member

Joined: October-02-2017 Location: Cleveland OH Status: Offline Points: 393 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Prop Nut and Cotter Pin Replacement Topic: Prop Nut and Cotter Pin ReplacementPosted: May-31-2021 at 1:45am |

|

|

1999 SN running Acme 422... would like to replace the nut and pin when I check the torque on the prop. Who is a good supplier for both? What size nut and pin do I need?

Thank you! |

||

|

Otto

|

||

|

||

MrMcD

Grand Poobah

Joined: January-28-2014 Location: Folsom, CA Status: Offline Points: 3771 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 3:23am Posted: May-31-2021 at 3:23am |

|

|

I don't have the requested size for the nut or cotter pin but if the prop was lapped in properly it will never move until you put a prop puller on there and Pull Hard to get it off. The nut is just there as a safety in case the prop is not lapped you will not lose it. No need to ever check the nut torque as that is not what holds the prop on. Properly lapped a prop will seat itself on the shaft taper so tight in normal operation it will never fall off.

If your prop was not lapped in properly you can hear it whenever you drop into reverse, it will make a little clang as the prop slips back and knocks on that nut. I got my first Nautique when I was 25, lots of time and always skiing but no knowledge. I ran a prop without lapping it in for a few years before I had to change a prop, I pulled off the nut and the prop came right off into my hand, no puller needed. The guy that sold me the new prop EXPLAINED things and I lap them now. The advisors on this forum have taught me the by the book method for prop lapping and it really does work for smooth and safe prop operation. Check in with Pete, I think he wrote the book on proper lapping and shaft alignment. Prop Nut torque spec is only about 35 foot lbs, that is not a lot but it is plenty to seat the prop if it is lapped properly.

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 6:05am Posted: May-31-2021 at 6:05am |

|

|

Otto,

You what a 3/4-10 nut. If you go with a "nyloc" type nut, then there's no need for a cotter pin. Also, do not use a stainless steel nut. With a SS nut on a SS shaft, there's a chace of thread galling (locking up) and then there's a big problem with removing the nut. Go brass.

|

||

|

||

Otto Throttle

Senior Member

Joined: October-02-2017 Location: Cleveland OH Status: Offline Points: 393 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 2:02pm Posted: May-31-2021 at 2:02pm |

|

|

Thank you gentlemen, I lapped the propeller using the Prussian blue and valve grinding compound Per the forums directions about three years ago. I was just looking around on the Acme propeller site, and they had instructions for installation and it included nothing on lapping the prop. I would like to change out the nut just because it’s older, and I don’t wanna have any problems. It’s always good to have spares around! At least that’s what my depression era father taught me! Happy memorial day to all you guys! To all of our veterans thank you for your service!

|

||

|

Otto

|

||

|

||

Otto Throttle

Senior Member

Joined: October-02-2017 Location: Cleveland OH Status: Offline Points: 393 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 2:03pm Posted: May-31-2021 at 2:03pm |

|

|

What about the stainless cotter pin size?

|

||

|

Otto

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 2:34pm Posted: May-31-2021 at 2:34pm |

|

Ottto, Did you purchase a castellated nut requiring the cotter? I don't have a cotter to measure so off hand I'd say the cotter would be a .125" or .093" diameter and a couple inches in length will do. If too long then clip the extra off. You'll be clipping the end off anyway. Also, there's a correct way and a wrong way to cotter a castellated nut. Wrong is on the left, correct on the right.  |

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 2:45pm Posted: May-31-2021 at 2:45pm |

|

The lapping instruction isn't on the Acme web site. It comes on paper with their props.

|

||

|

||

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 3:19pm Posted: May-31-2021 at 3:19pm |

|

|

You could also watch their youtube video on how to improperly use a crescent wrench and how it also doubles as a hammer

https://www.youtube.com/watch?v=1lmTW5lXA88

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: May-31-2021 at 3:45pm Posted: May-31-2021 at 3:45pm |

|

You'd think Acme's kit would have the proper tool. Using the adjustable as a hammer, sure is a true back yard hack job!  |

||

|

||

Otto Throttle

Senior Member

Joined: October-02-2017 Location: Cleveland OH Status: Offline Points: 393 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-02-2021 at 3:24pm Posted: June-02-2021 at 3:24pm |

|

|

Just for your information, the cotter pin size is 1/8” x 1 3/4.

|

||

|

Otto

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-02-2021 at 4:00pm Posted: June-02-2021 at 4:00pm |

|

Good to know. Thanks. You'll have plenty of length to cut the ends off. Did you go with the castellated nut?

|

||

|

||

Otto Throttle

Senior Member

Joined: October-02-2017 Location: Cleveland OH Status: Offline Points: 393 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-02-2021 at 4:19pm Posted: June-02-2021 at 4:19pm |

|

|

Yes I did! All from N3 Boatworks...Barb really helped me out. West Marine was clueless when I called them. Went with a sure bet!

|

||

|

Otto

|

||

|

||

KENO

Grand Poobah

Joined: June-06-2004 Location: United States Status: Offline Points: 11163 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-04-2021 at 8:20pm Posted: June-04-2021 at 8:20pm |

|

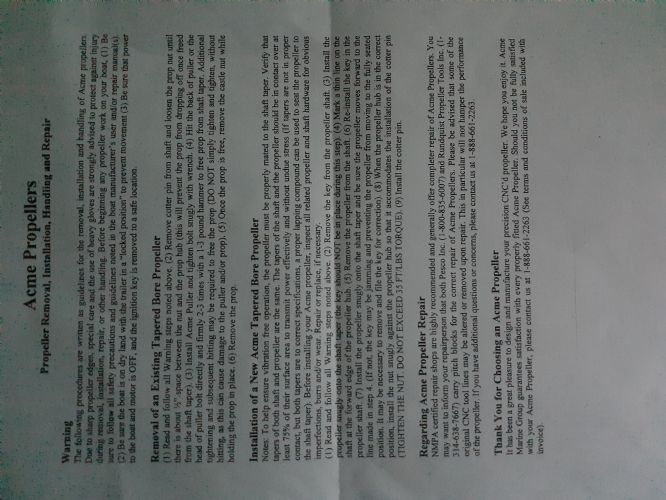

And here's that paper that comes in the Acme box along with that big hunk of CNC machined casting Rotating and making it bigger is optional.   |

||

|

||

Post Reply

|

|

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |