Prop shaft strut bearings

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=12019

Printed Date: November-13-2024 at 9:44pm

Topic: Prop shaft strut bearings

Posted By: slalomjunky

Subject: Prop shaft strut bearings

Date Posted: September-23-2008 at 4:44am

|

question about strut bearings. Has anyone replaced one themselves? Is it a bad job if you have a puller? any strut damage by using a puller such as the one listed on skidims site? Skidims bearings are also 2 pieces instead of 1 4". Is this a better system or is it just for convenience pressing them in? Once the set screws are loosened and with use of a puller are the bearings easy to get out? what about removal of the shaft coupler from the shaft? is it worth attempting myself or having a mechanic do it? ------------- Utah '94 Ski, '03 Malibu SS LXI |

Replies:

Posted By: 8122pbrainard

Date Posted: September-23-2008 at 8:50am

|

Kerry,

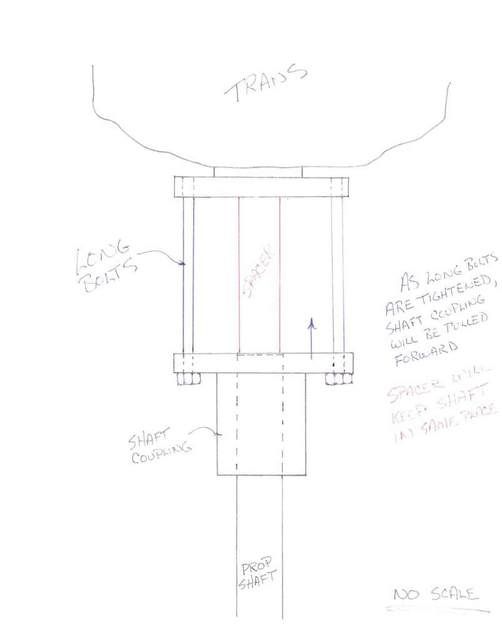

I really don't think many people get that puller to remove the old cutlass bearing. I as well as most will cut them out by using a hack saw. Put the blade through the shaft bore and assemble it on the saw frame. Doesn't take much cutting. I haven't heard of any advantages of the two piece bearing design. I feel the engineering concept is to get the forward section as far forward in the strut as possible to reduce possible prop shaft whip. I'd just go with the standard 4". Yes, the coupling removal from the shaft can be a challenge. The bore to the shaft is a interference fit so a puller is needed or most will use the "spacer and long bolt trick". This is a old sketch showing long bolts but threaded rod is even better - you just keep running the nuts up instead of having to change to shorter bolts!

Now, if you do take on this job, (we'll be here to help) and you find the coupling to be loose on the shaft, then you have fretted the coupling/shaft due to running with it misaligned. A new coupling and possibly a new shaft is needed. BTW, with the shaft out, it's a great time to check it for straightness. Getting the coupling back on the shaft requires the coupling to be heated so it expands. This PITA is why the double taper ARE shaft/coupling systems are so popular! (easier to remove too!) Keep us informed. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: M3Fan

Date Posted: September-23-2008 at 9:55am

|

Ah- putting the blade through, THEN assembling the saw- brilliant idea. Would have saved me probably a full hour of cutting. I was just hand holding a blade using one of those little blade handles. For next time, I guess. ------------- 2000 SN GT40 w/99 Graphics/Gel 2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

Posted By: anthonylizardi

Date Posted: September-23-2008 at 5:12pm

| I tried a bolt puller and beating the heck out with an air hammer. The only thing that worked like a charm was the long bolt with the socket in between. Make sure you adjust the bolts evenly. I had an impact gun set in the lowest setting. It speed up the process. After that and finding my shaft was bent I bought an ARE. |

Posted By: slalomjunky

Date Posted: September-23-2008 at 6:57pm

|

8122pbrainard,

thanks for the info. I understand the spacer and long bolts. Is the spacer pushing against the trans shaft or is that half of the coupling solid and the spacer is pushing against the coupling only? any problem cutting into the strut while cutting the bushing? My experience with doing this type of operation is that the saw blade has just enough deflection to cut at each end and not as much in the middle of the 4in bushing. after cutting what are you using to push out bearing? ------------- Utah '94 Ski, '03 Malibu SS LXI |

Posted By: M3Fan

Date Posted: September-23-2008 at 7:15pm

I just went though this. On the trans side, that half of the coupling is bolted in with a giant bolt. At least it is on my PCM PP trans. It's tough to avoid cutting into the strut but a little bite into the strut bore won't hurt anything. ------------- 2000 SN GT40 w/99 Graphics/Gel 2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

Posted By: 8122pbrainard

Date Posted: September-23-2008 at 7:35pm

|

Kerry,

Don't worry about the trans end, I've never had a problem nor have I ever heard of one. Maybe Eric has but I've never heard him comment on it. Just as Joel mentioned, don't worry about nicking the strut ether. Yes the saw blade may deflect and you may rock slightly with the sawing. Start with a new blade that isn't bent already. What I try to do is cut almost through the old case of the cutlass and then using a cold chisel or punch, curl the bushing inwards on itself - then cut some more. Grab it with a vise grip and it will pull right out. Now, getting the new one in is easy. Use a piece of threaded rod nuts and fender washers on the ends to press it in. You can tap it in with a block of wood and hammer but be very careful! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: behindpropeller

Date Posted: September-24-2008 at 11:41am

|

I have a puller I made...

I will lend it out if you want. Tim ------------- |

Posted By: slalomjunky

Date Posted: September-25-2008 at 3:44am

|

I appreciate all the info. Nice to get a lot of knowledge before starting a project like this. do any of you ever get parts from go2marine.com? I was on their site and they have a 4" bushing(one piece) on sale for $49.11. are there better/worse quality depending on manufacturer? Once I have all hte prep work done and am ready to pull shaft aprt and complete the instal how long will it realistically take me? what about realigning the shaft to engine? I attached the info on the bushing from go2marine.

Rubber Sleeve Stern Bearings - Naval Brass Mfr. Duramax Marine $49.11 - $283.00 Full molded type Duramax rubber-lined Naval Brass Sleeve Bearings adapt equally well to strut and stern-tube mounts and are often used effectively as rudder-stock and pintle bushings Bearing diameters are precision fitted to the designated shaft size with the correct clearance for efficient water lubrication External brass shells are machined and polished to provide easy fitting Specially formulated oil and chemical resistant nitril rubber is securely bonded to the shell Units with thin shells are available for the struts of small craft Sleeve Bearings are usually install by light press-fitting and locked in place with cone-pointed set screws ------------- Utah '94 Ski, '03 Malibu SS LXI |

Posted By: 8122pbrainard

Date Posted: September-25-2008 at 7:50am

|

Kerry,

I've used Go2 several times without any problems. They seem to carry all the good brands at very good prices. Yes, That's the traditional cutlass bearing you found. As far as the time it will take you to do the job, that's a tough one! There are too many variables. To R&R the shaft will take the time. 2 hours to all day?? Are you planning on putting your old shaft back in? Do check the shaft fit to the coupling and check the shaft for straightness. The best way is with the shaft set in V blocks and then a dial indicator. Now, strut/shaft/log/engine alignment?? When you get the shaft out and before you start cutting out the bearing, take a look at the wear pattern on the ID of the bearing. It's a good indicator of a bent or misaligned strut. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: eric lavine

Date Posted: September-25-2008 at 10:18am

|

one bit of advice when cutting into the strut, cut into it at the 12 O'clock position where all the meat of the strut is in case you cut to deep. I have tried many times with a puller to pull these bearings and its almost impossible, the best method is cutting them with a sawzall and 10" fine metal blade ------------- "the things you own will start to own you" |

Posted By: slalomjunky

Date Posted: September-25-2008 at 1:16pm

|

Eric,

makes sense to cut at that position but definitely a little harder to see and apply the right amount of pressure. Are you first cutting out the rubber portion to be able to get a good look at the brass and not to bind the blade? Pete, I understand that usual wear is on the bottom. do you realign like this or try to correct to have more even wear? What is the best way to move engine? Rear mounts do have threaded height adjustment but not lateral. I have never hit anything, no dings in prop at all ever. Should i still be worried about bent hardware? shaft should go through the direct center of shaft log correct? How is adjustment made for this if it is off? the waterseal and hose which hold it will be basically alignining the shaft from the strut to the log. I can't see how this can be changed much, rather engine has to be moved to align, corrrect? am I missing something? thanks Kerry ------------- Utah '94 Ski, '03 Malibu SS LXI |

Posted By: 8122pbrainard

Date Posted: September-25-2008 at 1:43pm

|

Kerry,

Yes under normal conditions most of the wear on the cutlass will be on the bottom. This this from the force of the water against the hull pushing down on the prop/shaft. Look for uneven wear top to bottom and port to starboard. This would indicate that the shaft isn't parallel to the bore of the strut. Yes, the strut can be aligned by using flat washers to shim the base to the hull. They can also be bent or twisted back to normal. Prop shops usually do this or someone with a press. The key thing is you want the shaft to be roughly centered in the hole in the hull/shaft log. This will be by putting the shaft in the new bushing and then feeling (by turning) the shaft to find where it's comfortable meaning it's close to parallel. Hopefully it will then line up with the hole. You don't want to pull the strut unless absolutely necessary. Have you run across Eric's pictorial thread on engine/shaft alignment yet? If not, I'll find it and give you a link to it. If you haven't aligned lately, I strongly recommend it. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: anthonylizardi

Date Posted: September-25-2008 at 2:42pm

|

Kerry,

If you can while you have the shaft out check the aligment. My strut was bent and the shaft was straight except at the end. This how I checked it using an almost V-block: http://www.correctcraftfan.com/forum/forum_posts.asp?TID=10392&KW=anthonylizardi&PN=0&TPN=3 - shaft aligment Good luck |

Posted By: behindpropeller

Date Posted: September-25-2008 at 3:53pm

Took me 25 minutes to get mine out with the puller I made. No cutting. ------------- |

Posted By: eric lavine

Date Posted: September-26-2008 at 10:13am

|

the last one i did didnt budge with heat and the tool, it started to mushroom the bearing,

i always atempt with the tool first but always end up with the saw, once in a while they will slide right out with the tool....then that means the new one slides in loose and get out the locktight ------------- "the things you own will start to own you" |

Posted By: behindpropeller

Date Posted: September-26-2008 at 11:28am

|

I have a threaded puller, not a slide hammer like ARE sells.

I did put the new one in with red loctite....hope I never need to get it out!!! Tim ------------- |

Posted By: 8122pbrainard

Date Posted: September-26-2008 at 11:49am

|

The brass wall thickness of the cutlass being very thin (.040 to .050??) it really doesn't give much of a surface for the puller plate to grab. If there is any corrosion between the strut and cutlass and or burrs from the set screws it sure makes pulling them a challenge. I've even had issues with getting the set screws loose. They are a shallow socket head and not much bite for the allen wrench. At least the allens are better than the early slotted soft brass ones!!

If the puller works, great! If not then saw it out. I personally feel sawing is quicker. Defiantly if you have the Sawsall. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: slalomjunky

Date Posted: September-26-2008 at 1:14pm

|

Sounds like I will have a great time with this project. If it is loose comming out and going in are you putting loctite on the exterior brass surface of the bearing? or just on the set screws? What about shaft wear st the bearing site? anything in particular to look for?(except for the obvious) Is factory alignment of the strut usually pretty good? and maybe I won't have to worry about the strut alignment with the shaft log(I Hope). Thanks for all the advice. when I get the time this fall I will have to get this project going and see how it goes. I have not run across the pictorial alignment thread. That would be nice to see if you can find the like I would appreciate it. thanks Kerry ------------- Utah '94 Ski, '03 Malibu SS LXI |

Posted By: 79nautique

Date Posted: September-26-2008 at 1:30pm

WELL that doesn't sound too bright since it's a service item and will need replaced again at some time. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=756&sort=&pagenum=1&yrstart=1979&yrend=1979 - 79 nautique |

Posted By: anthonylizardi

Date Posted: September-26-2008 at 1:31pm

Tell about the shallow socket head. I stripped both of them. I didn't want to deal with this and since I was sending the strut to get it straight I pay them to remove the set screw. Tell about the shallow socket head. I stripped both of them. I didn't want to deal with this and since I was sending the strut to get it straight I pay them to remove the set screw.

|

Posted By: critter

Date Posted: September-26-2008 at 1:39pm

|

Alignment by Eric.. Good reading

http://www.correctcraftfan.com/forum/forum_posts.asp?TID=6037&KW=eric+lavine - Alignment ------------- 1980 Ski Nautique 1966 Barracuda |

Posted By: behindpropeller

Date Posted: September-26-2008 at 4:34pm

Thats what a torch is for. ------------- |

Posted By: WakeSlayer

Date Posted: October-16-2008 at 4:32pm

|

I am about to begin doing some maintenance stuff on the Mustang.

- Shaft and rudder packing, as I take on a little water. - steering cable - cleaning up the wiring - cutlass bearing, and alignment and a few other little items. I looked at the cutlass bearing last night, and it is perhaps half (maybe less) worn just on the bottom end and fine the rest of the way around. The propshaft spins freely from the prop and from the trans coupler with hardly any effort at all. The coupler is perfectly aligned all the way around. My question is; Do I really need to replace the cutlass bearing in that condition? I already have it, and the threaded rod to make a puller, so cost is no issue. When is it required ? PS: Pete, thanks for the diagram!! ------------- Mike N 1968 Mustang |

Posted By: 8122pbrainard

Date Posted: October-17-2008 at 11:12am

|

Mike,

Generally if you can move the prop shaft up & down and side to side then it's time for a new cutlass. Wear on the bottom only is normal. It's from the water (prop wash) hitting the hull causing more downward pressure on the prop/shaft. Make sure the wear is even and not opposite (aft-bottom, forward-top) which would indicate a strut to hull misalignment. You can have a misaligned strut to the hull and still have good engine to shaft alignment! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: WakeSlayer

Date Posted: October-17-2008 at 12:38pm

|

Thanks Pete. I will look and the fore part of the shaft with a mirror this weekend. I have an very teeny vibration, but suspect the propeller after inspecting it. I want to learn to do this stuff, but not if there is no reason to. I can always do it later. It turns so freely that i have to question whether it needs it.

I have a second question about the packing. I had bought a length of 3/16 Gore-tex packing. Is this correct for the 1" shaft on a Mustang/289? Can I also, get a brief explanation on how to to the shaft and rudder packing? I think I have it figured out, but.... ------------- Mike N 1968 Mustang |

Posted By: 8122pbrainard

Date Posted: October-17-2008 at 1:16pm

|

Mike,

Since you mentioned the shaft turning very freely (a second time) do take a close look at the cutlass again. It may be time - the cutlass itself will produce drag on the prop shaft. You are going to need the 1/4" packing. I can't remember the years of the 3/16". Tim has mentioned them but it was a lot later (late 80's?) than your 68 The packing is wrapped arount the shaft in 360 degree segments. The ends of the segments are staggered 180 degrees. It usually takes about 4 segments to fill the packing gland. Don't overtighten the nut. Let it run (wet) and then tighten it if needed. The gland may run warm at first but never hot. If it gets hot, then the nut is too tight. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: WakeSlayer

Date Posted: October-17-2008 at 1:53pm

|

When I say freely, it is not "loose" just doesn't take more than light pressure to spin it. And it is smooth turning as well. There is no play in the bearing either.

I will call and get the 1/4 going. thanks ------------- Mike N 1968 Mustang |

Posted By: gcarbone

Date Posted: October-20-2008 at 3:11am

| Besides being able to move the prop shaft up and down and side to side while its in the trailer - are there any performance symptoms when the boat is in the water to help determine if you need a new cutlass bearing? |

Posted By: 8122pbrainard

Date Posted: October-20-2008 at 7:43am

A worn cutlass will cause vibration as well but vibration can also come from a bad shaft and or prop. Out of the water inspection is best. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: October-20-2008 at 5:03pm

|

Thanks Pete, I will check it this week but I have a feeling I will be replacing that as well, I'll keep you posted. I can use this thread as a guide.

Running it while it needs a cutlass will result in tranny damage right? thanks Greg |

Posted By: 8122pbrainard

Date Posted: October-20-2008 at 6:58pm

|

Greg,

It's really bad alignment that will damage the trans. When the shaft isn't aligned to the engine, you are basically trying to make a solid piece of shaft bend. This force then loads the output bearing in the tail end of the trans. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: October-20-2008 at 10:28pm

|

Got it - Thanks for the info. Turns out I will need to change the cutlass...I am getting familiar with how to do that, but its getting the shaft out and back in correctly that makes a new boat owner a little nervous.

I never had any vibrations before I took it out so I think the shaft is fine and when I look at the alignment, I cant really see any uneven gaps by eye but will measure them. So hopefully its just the bearing and everything goes smoothly. |

Posted By: 8122pbrainard

Date Posted: October-21-2008 at 8:01am

gc, Are you looking for a gap between the coupling halves? They do need to be unbolted to check - others have made this mistake. You will be measuring for a difference in the gap top to bottom and side to side. The coupling halve faces should be within .003". this is telling you the shaft is going straight out from the engine. Picture the coupling halves at your elbow. If you bend your arm, one side of the gap between the coupling will open up. When your arm is straight, the gap will be equal all around it. Keep us posted and we'll walk you through the whole process. There are some decent threads too. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: October-21-2008 at 11:54am

|

Thanks Pete, I will unbolt to check the alignment. If I do need to re-align, I wanted to kill two birds with one stone this winter while its on the trailer but have read and understand that an in water alignment is best. So I should change the bearing this winter but should wait to align in the spring when she floats right?

I need to re-read some of these threads as I am still foggy on the alignment through the bearing/strut and shaft log through the hull - I read its a feel thing, I just dont want to screw anything up seeing as I have never done it and especially since it was a real smooth boat when I layed it up but I spent the bearing. So it should be just that bearing replacement - so what can I screw up when I put the shaft back through to the transmission? ------------- 96 SN |

Posted By: 8122pbrainard

Date Posted: October-21-2008 at 12:56pm

|

gc,

Do everything on the trailer and then a in water double check is recommended. Pulling the shaft if preferred to pulling the strut for the new cutlass bearing. You don't what to have to do a strut alignment if not needed. You will know more when you get the new bearing installed. Yes, the alignment starts at the strut and then goes forward. I'm glad you picked up on that. Checking the strut to the hull hole/shaft log is "by feel". It's really finding the spot (angle) where the shaft turns freely in the bearing and then seeing if that's the spot where the shaft is roughly centered in the hole/log. You're not going to screw anything up!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: October-21-2008 at 3:43pm

|

Thanks Pete - I think I understand what I need to look for...I'll use the threads but will probably triple check with you guys. Wont be able to get to it until mid-Nov. at the earliest. I am going to get a cutlass from the site you refered to in another thread. are there year ranges that all use the same size...I have a 96, if someone knows what demensions I need that would be helpful.(and lazy on my part, but my boat is kept an hour away - sorry) ------------- 96 SN |

Posted By: gcarbone

Date Posted: November-01-2008 at 3:07pm

|

I finally got a chance to get to my boat and checked out the movement the shaft had, thinking I need a bearing but the shaft barely (maybe 1/16'' or less)moved up and and down and didnt move from side to side at all. I have read over a lot of threads based around shaft, coupling and rudder removal and the nightmares of getting those back in and together correctly...which are required to change the cutlass.(right?)

So.... now I wonder if I really need to do the strut bearing based on the minor movement up and down of the shaft and risk end up being in worse shape from everything else involved. I would love to hear some input from you guys on this...thanks. Greg ------------- 96 SN |

Posted By: 8122pbrainard

Date Posted: November-01-2008 at 5:34pm

|

Greg,

Think of it this way: You have all winter to do this and consider the learning experience!! I feel you need a new bearing!! Have you opened up the coupling and checked the alignment yet? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: November-01-2008 at 6:05pm

|

Havent checked the alignment yet - just put it in storage this morning and only had time to see how much the shaft moved. I will check the alignment next time I am able to drive to it and bring some tools. I did notice before I left her this morning that i could "wiggle" the rudder a little bit...is that supposed to be solid tight too or is a little movement OK?

I bought this boat in August and had ZERO issues with it, all my buddies were jealous about how smooth it was - now I am reading about freezing and baking shafts and couplings so i think that is why I am apprehensive to dig in...but I'll get after it, as long as you guys don't mind me killing you with questions. ------------- 96 SN |

Posted By: M3Fan

Date Posted: November-01-2008 at 8:21pm

|

The rudder can wiggle just slightly- nothing too out of the ordinary there.

Don't let the freezing and baking shafts scare you. It's all pretty straightforward. I had the guys on this site talk me off the ledge during my cutlass bearing replacement. My shaft had a little bit of play up and down like you describe. After doing the bearing swap there was not that much of a difference in the boat's smoothness so in retrospect I probably would not have done it. However, I'm really glad that I did because I learned quite a lot in the process. ------------- 2000 SN GT40 w/99 Graphics/Gel 2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

Posted By: gcarbone

Date Posted: November-02-2008 at 10:30pm

|

thank you for that perspective Joel...looks like I am in the same spot you were. I am a young guy, I have a lot to learn and hopefully many more years to do it in - but I also want to avoid creating more problems and having to be talked off the ledge as well. I think when I can confirm that my alignment is all set, I might not change the bearing until early early spring when I can put it back in the water to check the performance to see if the bearing really needs attention(and still have time to fix it before summer)...I would be able to tell from obvious vibrations right?

Pete, I'm not ingoring your response, I think the outside temp is helping to push this till spring when it warms up some and figured I will be able tell for sure by then with a water test. ------------- 96 SN |

Posted By: gcarbone

Date Posted: November-15-2008 at 4:52pm

|

Finally had time to drive to my boat, off-site storage sucks - Couplings came apart very easily and alignment seemed good enough to leave alone. Side measurements were .003 or less and top was .004 and bottom was .000. I think I will leave it as is, hate to mess around to get .001 top to bottom adjustment.. agreed?

Was wondering though as I saw the shaft log through the hull...isnt there supposed to be some type of lubrication? It has been out of the water since September but it didn't look like there was anything at all...is it just lubricated with water when the shaft is spinning? ------------- 96 SN |

Posted By: anthonylizardi

Date Posted: November-15-2008 at 5:36pm

| It is my understanding that water should lubricate the cutlass bearing and shaft seal. Don't ever run when the boat is outside. I did it to test and end up wearing out the cutlass bearing. That's was back then when I didn't know anything at all, then I found CCF. |

Posted By: gcarbone

Date Posted: November-15-2008 at 6:13pm

|

how did you know you wore out the bearing without it being in the water ------------- 96 SN |

Posted By: anthonylizardi

Date Posted: November-15-2008 at 6:38pm

|

Because CCF guys told me. It made a terrible sound and the the prop stop while on idle. I put on reverse and the same sound. On the water ran but I knew I was on trouble. When I removed the shaft because I had a bent strut I saw how the bearing was wear out because little chunk of rubber were missing. All I know it should not be done. Here is my http://www.correctcraftfan.com/forum/forum_posts.asp?TID=10392&KW=anthonylizardi&TPN=2 - bent strut

Also, another thing was that I was unable to turn my prop by hand. Now, understand that all this was compunded by a bent strut. Now, how are the normal indications under normal conditions, I don't know. All of this is an elimination process. Vibration will be a good indication if the prop and shaft are fine. |

Posted By: 8122pbrainard

Date Posted: November-15-2008 at 7:06pm

|

gc,

No lube in the shaft stuffing box. It is lubricated by the graphite packing if you use the old type or Teflon with the newer packing. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: November-15-2008 at 7:40pm

|

Cool got it.

Any thoughts on the Alignment? Greg ------------- 96 SN |

Posted By: SNobsessed

Date Posted: November-15-2008 at 7:41pm

GCarbone - You might want to recheck it in the spring, while the boat is floating level. Mine changed about .005" between trailered & floating. So yours could get better or worse once it's floating. Also turn the shaft to each 90 degree position to see if your gaps change. This is a good double check for a bent shaft. Also, It isn't hard to correct the alignment, so there is no reason not to get it to the .003 spec, at least in my opinion. Good luck! ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: BuffaloBFN

Date Posted: November-15-2008 at 8:47pm

From what I know about you I wonder why this doesn't freak you out?!!?  ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: 8122pbrainard

Date Posted: November-15-2008 at 9:08pm

gc, Chris is correct that once your in there adjusting it's really not that hard but, shoot for .000"!!! The .003" is the max. recommended. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: SNobsessed

Date Posted: November-15-2008 at 10:50pm

|

Greg - What you DON'T know is the scary part. Like how far down the economy will go! ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: gcarbone

Date Posted: November-16-2008 at 12:41am

|

I can see what it looks like when its back in the water in the spring and if it stays the way it is i will try to adjust it...

With a .004 "12 o'clock" reading and .000 "6" reading, do the rear mounts come down or front mounts come up...I read the thread but didnt really pull the answer from it. seems crazy to me that moving the engine 1/1000 can really make that big of a difference....would have never thought - appreciate the input guys. let me know if there is more. as far as the economy - who knows right? I'm just pumped gas is as far down as it is...should we stockpile for summer!? Greg ------------- 96 SN |

Posted By: SNobsessed

Date Posted: November-16-2008 at 11:07am

|

GCarbone - What I did is hold a .002 feeler against the tight spot (6 oclock in your case) & then adjust it so that the .003 will slip in but .004 won't. You could go to .005 if you want to only get it barely in spec.

You could adjust the rear mounts down or fronts up - I would do both a little in order to keep things centered. You need to loosen the pivoting fgeature anyway so as not to induce a torque preload on the rubber. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: 8122pbrainard

Date Posted: November-16-2008 at 12:33pm

Front or rear mount adjustment is determined by the shaft position at the coupling. With proper strut alignment and the shaft roughly centered in the log/stuffing box, is the coupling high or low? The closer you get the engine/shaft aligned, the happier the trans will be. Misaligned, the happier Eric will be!!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: eric lavine

Date Posted: November-16-2008 at 12:47pm

|

I feel like a football coach who sold the playbook to the other team lol, really, im starting to feel like the Maytag man ------------- "the things you own will start to own you" |

Posted By: gcarbone

Date Posted: November-16-2008 at 1:56pm

|

Pete, not really sure what your asking? I would think with the biggest gap being on the top at .004 based on the readings, I would say my coupling is high..is that what you mean? If it is high, which mounts are adjusted first?

Thanks Chris...As far as the mounts, are the adjustments relative to MA measurements...for example, I would need to adjust mounts actually .000 -.004 to match coupling gaps or does the motor have to come up or down say 1/4" to match .003 MA on the coupling? is there a rough estimate ratio? Adjustments are easy? ------------- 96 SN |

Posted By: 8122pbrainard

Date Posted: November-16-2008 at 6:50pm

They are easy!! Just takes building a picture in your head. I will say that at times they can be frustrating! Ok, the gap is on the top so the angle of the engine needs to be increased. Yes, this can be done with raising the front, lowering the rear or both. What you don't want is to have the centerline of the trans coupling pushing the shaft to the hull/strut/log out of that alignment. Why do you feel the shaft is high? Make small adjustments and keep a eye on where the coupling is going. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: November-17-2008 at 11:37am

|

I don't think the shaft is high, I think i just misunderstood your post regarding that. i think i just have a MA that requires adjusting as you mentioned either front up, rear down or a little of both...I will get after it again when I am able to physically get to my boat.

Seems as though vertical adjustments are easier than horizontal though? It would be easier for me to understand these adjustments if I was able to walk into my garage to reference the mounts...but I have to wait 3 weeks and try to picture it in the mean time. ------------- 96 SN |

Posted By: Riley

Date Posted: March-28-2009 at 8:18pm

|

I'm going to order a strut bearing today. It appears that it's a 1" shaft, 1.25" dia strut bushing. Does that sound right? It looks like the one in there now is a plastic one, but there's not much left to it.

Does anyone know what size hose is needed for the stuffing box, and does the rudder port take the same size packing as the stuffing box?  ------------- |

Posted By: 8122pbrainard

Date Posted: March-28-2009 at 8:51pm

|

Bruce,

The 1" by 1.25" would be the correct cutlass bearing. If it isn't rubber with a brass shell, then most likely it's one of the old "trick" Ryertex (phenolic) bearings. They really didn't last as long as the rubber/brass but were less expensive. What's the surface of the shaft look like? Any scoring from the bearing? Don't know exactly the hose size on the log but I'd guess 1.75" ID. Better measure it. I'm sure the stuffing on the log will be 1/4" but the rudder ports vary. You'll want to measure it too. Are you sure it needs changing? You may get away with just tightening it. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Riley

Date Posted: March-28-2009 at 9:19pm

|

Pete, I have no idea if it needs changing or not, just thought I ought to do it while everythings apart. The stuffing box has never been out as it's partly fiberglassed in. The hose is cracked, so I'm going to replace it. The rudder is a lot easier to get to with the tank out. I guess I'll take it apart and see if I can get the old packing out and measure it. I'm lining up parts now. Hopefully, within 2 weeks the snow will be gone so I can pull her out and start working on it. I want to bring a correct Craft to Green Lake!

I'll have to inspect the shaft. It's an old brass one. It was pretty loose in the strut, but ID measured about 1 1/8". ------------- |

Posted By: 8122pbrainard

Date Posted: March-28-2009 at 10:37pm

|

Bruce,

From your description, it's time for a new cutlass bearing! I'd suggest the old style rubber/brass with the brass shaft. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcarbone

Date Posted: March-29-2009 at 11:41am

|

Bruce, I am not far from you - when you are getting ready to put the coupling and shaft back together and back into the transmission let me know. If you didnt mind company I'd love to see how that is done first hand. I have questions about getting the shaft back to the transmission correctly. thanks - Greg ------------- 96 SN |

Posted By: Riley

Date Posted: March-29-2009 at 11:53am

|

Greg, I'll be glad to let you know and invite you over, but you should know I cheated. I pulled the engine, so I did not have to separate the shaft from the flange.

Still, should be interesting, (or even amusing) watching us connect the couplings together as we will be doing our first alignment and we don't have adjustable engine mounts. Where are you in NH? ------------- |

Posted By: gcarbone

Date Posted: March-29-2009 at 12:04pm

|

I live in Concord - but we have a place in Scarborough and Acton (Square Pond).

I grew up skiing behind my grandparents Mustang just like yours, been trying to buy it back for years. cant imagine you are far from Scarborough and we are up there on weekends a lot in the spring so I look forward to hearing from you. ------------- 96 SN |

Posted By: 86BFN

Date Posted: March-29-2009 at 12:49pm

|

Has any one tried the new XPC bushings from Skidim? I was just wondering as I'll be changing mine soon.

http://www.skidim.com/prodinfo.asp?number=OJ2032B - XPC Strut Bearing Thanks in advance for the feedback. Steve ------------- 👣 Steve http://www.correctcraftfan.com/diaries/details.asp?ID=4057&sort=&pagenum=1&yrstart=1986&yrend=1986" rel="nofollow - 86 Barefoot Nautique 89 Martinique Former Owner: 93 Hydrodyne 350 MAG |

Posted By: Riley

Date Posted: March-29-2009 at 3:55pm

|

Greg, We're about 45 minutes from Scarborough. I'll let you when when we get near.

86BFN, those plastic bushings look like what is in mine now. ------------- |

slalomjunky wrote:

slalomjunky wrote: