More like a Briar Patch

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=12191

Printed Date: April-20-2025 at 12:45pm

Topic: More like a Briar Patch

Posted By: hasbeenskier

Subject: More like a Briar Patch

Date Posted: October-19-2008 at 11:33am

|

I am getting back on the BFN. I HATE grinding.

I climb out that boat looking like a powdered doughnut. ------------- hasbeenskier |

Replies:

Posted By: hasbeenskier

Date Posted: October-19-2008 at 11:36am

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: October-19-2008 at 11:38am

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: October-19-2008 at 11:40am

------------- hasbeenskier |

Posted By: BuffaloBFN

Date Posted: October-19-2008 at 1:36pm

|

Oh man...what a truely horrible association to put with 1 of my favorite junkfoods?!!? LOL

Looks like you're at the easy part now; and I am strangely envious! Thanks again for your help on mine. ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: hasbeenskier

Date Posted: October-19-2008 at 3:12pm

|

Hey Greg,

I have been thinking out loud.. just several more hours of grinding, then just a couple more hours of grinding, now I still have a couple left to get the remaining mat off the transom where the whole lifting ring assembly was glassed on. I am getting excited about the rebuild although it may take years.

bj ------------- hasbeenskier |

Posted By: eric lavine

Date Posted: October-19-2008 at 3:47pm

|

its the same concept as where you were at when JFK was shot, its something you wont forget, recently,after 2 weeks my finger got so purple and festured that i grabbed the razor and started cutting, I picked, i probed and finally discovered the 1/4" piece of glass.....wear gloves ------------- "the things you own will start to own you" |

Posted By: hasbeenskier

Date Posted: October-19-2008 at 9:21pm

Yes suh Mr. Poobah! I am guilty... A respiriator yes... a face mask yes...gloves uh..... my grip is not as good. but you are right...sounds like... do what I say not what I do!

bj ------------- hasbeenskier |

Posted By: BuffaloBFN

Date Posted: October-19-2008 at 9:23pm

"What'd you say? Oh that...it'll grow back"?!!?  ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: jbear

Date Posted: October-19-2008 at 11:01pm

|

Listen to eric BJ...I remember the gouge you took outa your leg at the start of this project.

Looks like you about got it whipped tho. john ------------- "Loud pipes save lives" AdamT sez "I'm Canadian and a beaver lover myself"... |

Posted By: critter

Date Posted: October-19-2008 at 11:55pm

Looking really great BJ.. Eric is right on with the gloves... And I to remember that gouge to the leg...   ------------- 1980 Ski Nautique 1966 Barracuda |

Posted By: hasbeenskier

Date Posted: October-20-2008 at 11:18am

|

Oh Yeah that... gloves would not have helped the leg but, I'll yield, gloves it is. I'll get some new ones so it will be special.

bj ------------- hasbeenskier |

Posted By: jbear

Date Posted: October-21-2008 at 2:41am

|

How about wearing some long pants too.

john ------------- "Loud pipes save lives" AdamT sez "I'm Canadian and a beaver lover myself"... |

Posted By: eric lavine

Date Posted: October-21-2008 at 10:32am

|

those are meat removing gouges on the thigh, they scar, another good one that you will run across is leaving the grinder clicked on and plugging it in, speed racer!!! ------------- "the things you own will start to own you" |

Posted By: hasbeenskier

Date Posted: November-08-2008 at 11:05pm

|

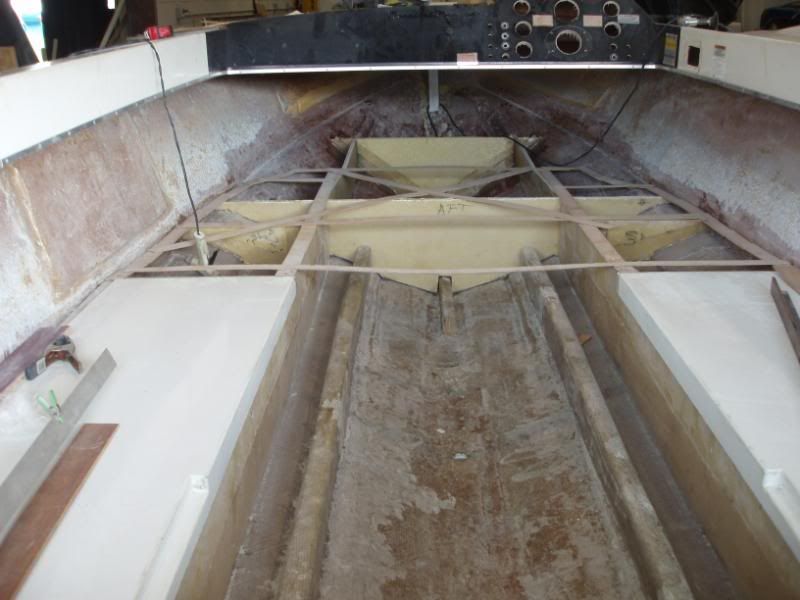

I had a good day today. I fabricated the new composite stringers to the 81 BFN. They are constructed of two layers of Divinycell H-80 5/8" (5 pound density), sandwiching two layers of 1.5 ounce glass mat in between.

Over the last week I laid up four 12 ft. strips of 24 oz.roven woven 12" wide along the length of the hull. Next, I am going to reconstruct the transom/lifting ring assembly. When i can set time aside to work on this project I get pumped up. bj ------------- hasbeenskier |

Posted By: JoeinNY

Date Posted: November-09-2008 at 1:08am

This is where you lost me, you got a picture of what your talking about here? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 7:29am

|

I have a photo of three of the four strips I will post. But as a better description, the strips are to strengthen/reinforce the bottom of the hull. They run from the transom forward 12', (overlapping of course.) ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 7:37am

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 7:45am

|

It is a little difficult to discern but there are three of the four strips as previously described, Two on the left one on the right. This was added to beef up the hull.

Somthing the original boat did not have in 81 is an aluminum engine cradle that will be added this time around I also get a bang out of going back to look at what it looked like before hand. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 8:19am

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 8:20am

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 8:26am

|

The two photos above are: 1st a shot of the foam used in the stringers, and 2nd preping to make a stringer. ------------- hasbeenskier |

Posted By: SNobsessed

Date Posted: November-09-2008 at 11:54am

|

Hasbeen - Interesting choice of materials for your stringers. Has anyone ever used this before? I assume the epoxy will not adhere directly to the PVC substrate - how will you tie all your glass layers together for torsional rigidity?

Also - what will your engine mount lag screw threads bite into? ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 12:47pm

|

Chris, Good Morning! Epoxy will work, however, I use polyester resin. These materials are widely used in marine applications. The composites are my choice over wood. They will not absorb water or rot.

The foam simply gives the stringer shape The wrapping of the stringer in glass provides the strength. I will say that I have an advisor that keeps me on course. I have mentioned him before. I call him the "Wizard" His name is Gary Baker. He owns a company that has built and rebuilt some of the vessels and rides seen at Univeral Studios Amusement Park in Orlando, Florida. In describing him GENIUS comes to mind. ------------- hasbeenskier |

Posted By: SNobsessed

Date Posted: November-09-2008 at 1:02pm

|

Good luck with your project. I can only add that sticking with a traditional wood core / epoxy resin construction would give you some legal protection in the future, as it is well tested. If you use an untested design & it fails, you could be liable for any resulting property damage or injuries. When you go to sell this boat, please disclose your construction to the prospective buyers. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 1:18pm

Thanks, Comosites are not experimental at all. You may know the better boat builders don't use wood anymore but, composites. The boat will be over built and better than original.I am not doing this for anyone but me. It is too much work and too much money to even justify. The down side is, the boat will out last me. It is a long process but stay tuned and Ill keep you posted on the progress.

bj ------------- hasbeenskier |

Posted By: 8122pbrainard

Date Posted: November-09-2008 at 2:20pm

The composite may not be considered experimental but when you follow the same stringer design, eliminate the structural strength of the wood and rely solely on the glass covering of the new "stringer" it certainly becomes experimental. The composite in todays boat construction doesn't follow the same shape as our old boat stringer system. When Joe did his boat with the Coosa board, he carefully researched the structural modulus. All Chris is saying and I'm agreeing with is be careful. A boat repairer is not the same as a boat manufacturer. Did you ask him about any failures? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: bkhallpass

Date Posted: November-09-2008 at 3:30pm

|

I understand you critiques/concerns. But, if I recall BJ used the same materials in his other boat and that seems to be working out well. BKH ------------- Livin' the Dream |

Posted By: 8122pbrainard

Date Posted: November-09-2008 at 5:31pm

|

Bj,

I'm glad you're counting on the glass around the H-80 and you had better be laying LOTS of it around the stuff!! This is especially true because you're using polyester and not epoxy resin. I was curious and looked up the specs. It's not much better than a wet noodle but at least it won't rot! Ultimate tensile strength - MPa Fir - 130 H-80 - 2.20 Tensile modulus - GPa Fir - 11 H-80 - .08 Shear modulus - GPa Fir - 4.1 H-80 - .0309 You have lost lots of strength without the Doug fir. Did you ever even look at the specs? Hopefully you're not just "winging" this project. Is Gary Baker a engineer (hopefully structural/marine). ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 6:41pm

|

I guess I have opened a can of worms. I have confidence in the approach being taken. I am not taking anything I do haphazardly. It is foolish and too costly to wing anything. I do not reject this type of discussion, I invite it. The proof is in the pudding. Wood VS. Composites & Epoxy VS. Polyester. That is why they make chocolate and vanilla. I'll keep you guys informed. ------------- hasbeenskier |

Posted By: 8122pbrainard

Date Posted: November-09-2008 at 7:57pm

|

B.J.,

Keep going! I love the ambition in a different direction and make sure you keep up with the pictures too. I didn't mean to discourage but rather point out some major strength differences that need to be compensated for when following the same stringer design using a different material. The biggest thing you have going for you is the fact that these early hulls were never engineered - They were over built using "seat of the pants" safety factors learned from many years of boat building. I mentioned epoxy because I really feel it is a better resin for boat building. Besides not being hygroscopic, it has higher strength, is better bonding and its flexural strength is higher than Polyester. IE. it's not as brittle and will bend more before shattering. The mixing ease with the exact ratio metering pumps can't be beat. The only bad thing is it's higher cost. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: SNobsessed

Date Posted: November-09-2008 at 8:00pm

|

BJ - You could ask a Marine Surveyor if he would accept a boat repaired with this material. If he buys it, then you can rest easy.

I am sorry to be negative - it is drilled into me to be skeptical as a Quality Engineer. We have a saying at work - In God we trust, all others must bring data. Please take lost of pictures because we have a long winter stretch ahead & need our fix of fiberglass work. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: hasbeenskier

Date Posted: November-09-2008 at 9:30pm

Thats it?..... I leave for a couple more hours of boat work expecting to return to more hammering. You guys have lightened up too easily!  I am kidding with you guys because, I truly appreciate your thoughts and points of view. It is thought prevoking for me. Expense is not an issue with me, it is preferences. Additionally, when I take on a task such as this I do not want to do it more than once. I am kidding with you guys because, I truly appreciate your thoughts and points of view. It is thought prevoking for me. Expense is not an issue with me, it is preferences. Additionally, when I take on a task such as this I do not want to do it more than once.

I will be posting progress reports and pictures when the project moves forward. ------------- hasbeenskier |

Posted By: the grinch

Date Posted: December-03-2008 at 1:55am

| You mentioned that you will be adding an engine cradle and I'm sure you're wanting more integrity for the pylon. Do you have a plan already for this? I'm doing a 79 BFN and I was considering the same thing. When I started my project, the pylon was barely hanging on and I want to insure this doesn't fail me in the future. |

Posted By: JoeinNY

Date Posted: December-03-2008 at 2:33am

Of course the 83 was my second CC floor and stringer job, my first one I used cross linked pvc foam for both the floor and stringers and didnt refoam. There was a serious change in lamination schedule however over the stock. There are definitely some tricks to it, but it can be done. Cant exactly screw down the seats or the motor mounts into the foam when your done. It did help that the hull on the 67 was very thick and the span between the sringers wasnt very far. The floor in the mustang is not as rock solid as the 83 but its plenty solid. Good luck, you should be fine. Be careful with the polyester though if it ends up brittle you dont have the wood to back you up, measure carefully. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: hasbeenskier

Date Posted: December-03-2008 at 7:19pm

|

Grinch:

I intend to use an aluminum engine cradle. It will be modeled after the ones used in the Ski Nautique. I hope to have it built this week end. It will be constructed to incorperate the pylon to reinforce and strengthen it's mount. It will also assist with the rigidity and strength of the main stringers. I will post photos upon its completion. Hey Joe, Thanks for jumping in. I am using polyester because I am so comfortable with it. I just bought a drum of it for this project. I expect to use about half. I intend to build the deck on a table reinforced with nida-core the surfaces will be layered enough to support any screws required ------------- hasbeenskier |

Posted By: JoeinNY

Date Posted: December-03-2008 at 10:16pm

|

I got to tell ya if your comfortable with polyester, epoxy would be like a walk in the park. Its just all around more pleasant to work with. I was able to make the entire floor of my mustang in one piece but I didnt get anywhere near the thickness on either the top or bottom lamination that would be required to hold a screw. The Aluminum cradle will definitely help, I used aluminum backing plates for my engine mounts but will consider a cradle when the boat finally hits the water again with the last round of engine upgrades. My main issue with using the lamination for the strength was ending up with flat surfaces on the stringers for the floor to mount to, I was unwilling to sand the tops of the stringers to the extent it would have taken. I considered making a mold for the the stringers on my 83 so I could end up with a dimensional product on the outside and just pour foam in the middle before laminating to the hull similar to the new construction boats but couldnt justify the effort so I went with the coosa method. Coosa is very easy to work with, eliminates the wood, but is very expensive, and while lighter than wood was heavier than the foam core method. To each his own, be careful, and try not to die. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: hasbeenskier

Date Posted: December-04-2008 at 10:51am

|

Thanks Joe I especially will focus on the try not to die part. By the way your 83 is beautiful. It is actually my favorite model. I love the Dreasden Blue hull with blue graphics version. ------------- hasbeenskier |

Posted By: the grinch

Date Posted: December-16-2008 at 12:32am

| Needing a fix! Tell me you have that engine cradle built. I'm waiting to see what you come up with before I build mine. In the mean time I'll keep grinding. There is no way a guy could do all of the required grinding in less than 40 hours. I don't see the end in site on my project. |

Posted By: JoeinNY

Date Posted: December-16-2008 at 1:23am

grinch what boat are you starting with? I don't see any reason to make a cradle any different from the one that was standard after 82, its a great design the engine and pylon are linked together and that pylon is going no where.

40 hours is a lot of grinding, make sure you have a diamond wheel

Bj thanks I was very happy to end up with the blue 83, I like the blue ones in general but the dresden blue with the tricolor stripes from 82-84 is probably my favorite as well. Mine could use some work on the hull and the stripes (you can see in the picture below how much more blue the deck is compared to the hull) but it looks good enough that I am hesitant to mess with it for a while. I almost felt bad adding the tower, stereo, and the non original interior install..

Almost. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: the grinch

Date Posted: December-16-2008 at 11:32pm

| I'm working on a 79 barefoot that went way beyond the time of needing a floor/stringer replacement. I do have a diamond wheel, however, I have the one from harbor freight which is configured a little different. Has anyone compared the two as to performance? Don't matter, I'm going to buy the Lowe's version anyway and give it a try. I was also wondering if anyone has done repair using adhesives? They are really setting some presidence with adhesives and thought I might do some experimenting on my project. |

Posted By: JoeinNY

Date Posted: December-16-2008 at 11:40pm

|

What kind of adhesives are you talking about?

Epoxy is pretty much the ultimate adhesive? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: the grinch

Date Posted: December-17-2008 at 12:08am

| I'm refering primarily to epoxy and urethanes used in the adhesion of fiberglass and smc truck hoods. These are all two part adhesives dispensed by either a manual or pneumatic gun and used in both the manufacturing and repair of truck hoods. i'm very familiar with the products as I've sold them for years, I was just wondering if anyone else has tried them. Of course, in the boat world, most of what is being used in mfg. is acrylic adhesives, which I could use, but just more familiar with epoxy and urethane. I would only be using these for bedding the stringers/supports and epoxy resin and mat will make the bulk of the strength, however, the epoxy adhesive is rated at 3200psi lap shear strength. My question to our tech guy was of course "too stiff"? The answer, was no, "we're crashing cars and trucks with this stuff with no problems". As far as gelcoat repairs go, I'm going to be doing something different as well. I'm going to paint the boat, however, will be using a different epoxy for the cosmetic repairs needed in the hull........long way from getting to this point, but I have a plan. |

Posted By: 8122pbrainard

Date Posted: December-17-2008 at 9:01am

|

Kirk,

I'm very familier with the Lord, 3M and Locktite product lines that include the groups of adhesives you are referring to. I've engineered robotic application systems here at the plant for gluing sub assemblies together such as truck body panels for our customers. Stick with the base epoxy resins for any work with glass because it needs to be saturated (wet out). Then add the needed fillers to the resin as needed to bed stringers or filleting. The wood should also be "wet out". I highly recommend CPES (a very low vis epoxy) You want the same adhesive system throughout. Don't mix different systems next to one another. We know epoxy works with glass and is compatible with the existing polyester. Since you sell these adhesives, you know that most are VERY specific to there application and not very forgiving. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: eric lavine

Date Posted: December-17-2008 at 10:17am

|

we use two part adhesives to hold panels on cars and trucks such as bed sides and qauterpanels, it eliminates welding and warpage, even at the cut line. i wouldve never of thought. its 3M. it smells good too.

Generally, the repairs you make to the boat are usually two fold in qaulity. alot of times you tear into the factory construction of the boat and see where they cut costs, you'll find alot of untreated wood, alot of sloppy work and if you compared apples to apples on the longevity of the repairs you make, compared to the factory construction of the boat, you really would think your repairs will last much longer than the factory construction, if you use that as a guideline you should get a minimum of 20 good years of service from the boat and alot depends on how the boat is cared for ------------- "the things you own will start to own you" |

Posted By: hasbeenskier

Date Posted: December-19-2008 at 10:48pm

Sorry Guys... I have been missing out on this thread. I have been very distracted with things like work and my dad's health issues. I haven't built the cradle yet and it looks like it will be after the 1st of the year. It is very hard for me to be patient with this process. As soon as I get a little roll going somthings interupts my progress. In my corperate days we called it "Task Interference"

bj ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:11pm

|

Reviving the post to post some updated pictures for your asmusement

bj ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:15pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:17pm

|

Should I try and reduce the size of the photo and if so how do I do it?

bj ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:25pm

|

The outboard stringers were extended up under the dash and couple of bulkheads were added.

bj ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:30pm

A photo of the pattern for a deck panel. Mateerials: Strips of a door skin, sissors and a hot glue gun. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:33pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:38pm

Making a form on a glass table of the door skin pattern of the deck piece. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:39pm

Shooting gel coat onto the glass top form ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:42pm

The deck section after it was laid up and popped off the table ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 9:43pm

Shazzam ------------- hasbeenskier |

Posted By: Luchog

Date Posted: July-09-2009 at 10:47pm

|

this is a really interesting method!!! can you post more pics on the lamination process???? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2095" rel="nofollow - 1980 Ski Nautique Commander 351W |

Posted By: hasbeenskier

Date Posted: July-09-2009 at 11:00pm

|

Give me a day or two and I waill post more pictures of the lay up. It is pretty basic. A 1.5 ounce mat skin against the gel. Then a double layer of 1808 then a 1/2" nidacore then finished of with another 1808. ------------- hasbeenskier |

Posted By: Luchog

Date Posted: July-10-2009 at 12:27am

|

do you wax the glass prior to aplying the gel? I must say that's a very clever way to make a floor without a mold!! ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2095" rel="nofollow - 1980 Ski Nautique Commander 351W |

Posted By: hasbeenskier

Date Posted: July-10-2009 at 12:54am

|

Wax will not work. It is a mold release. ------------- hasbeenskier |

Posted By: akabulla

Date Posted: July-10-2009 at 8:00pm

|

Thats pretty cool! How are you going to lay the carpet so you don't see the edge from the floor to the side? I looks like there is a lip.

Keep the pictures coming! |

Posted By: 8122pbrainard

Date Posted: July-10-2009 at 9:26pm

|

Bj,

I admire your ambition with the stringers and certainly the floor pan (even though it's not original!!). Did you ever consider and talk to your glass guy about using one of the diamond non slip patterns on the floor pan like the 60's Mustangs? Considering what I've seen in the pictures, I'm sure he knows about the stuff you get for the pattern. Just curious!! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: BuffaloBFN

Date Posted: July-10-2009 at 9:28pm

|

Doin' the South proud! ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: hasbeenskier

Date Posted: July-10-2009 at 9:29pm

|

The edges will be glassed smooth and the surface will be gel coated with a pumice added to provide a non skid surface. No Carpet. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-11-2009 at 12:46pm

|

Pete,

I missed your post about the diamond pattern. Yes I am very familiar with it and the boat yard even has a form of it. I personally prefer the pumice non-skid surface. I have a spearfishing buddy with the diamond non skid on his Pursuit and those little diamonds are sharp. (LIke when kneeling on it) The diamond pattern does scrub clean easier though. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-11-2009 at 6:35pm

Subsequent to glassing down the deck, holes were cut in to the deck for the insertion of foam. Upon it expanding out the holes and thereby filling the compartment cavity the pucks were replaced and glassed back. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: July-11-2009 at 6:35pm

------------- hasbeenskier |

Posted By: akabulla

Date Posted: July-14-2009 at 12:14am

| Sorry if I seem dense but I am really intrigued by the floor and don't fully understand the construction. If I understand correctly you used something like plexiglass or lexan for the base. Then applied your laying process on top of that and the plexiglass stays as part of the floor or you removed it before glassing it in place? |

Posted By: hasbeenskier

Date Posted: July-14-2009 at 12:01pm

|

The Work table is tempered window glass. The molds are built on the top of the glass. Upon completion the deck section is popped up from the table top and flipped over giving a very smooth gel coat surface. ------------- hasbeenskier |

Posted By: akabulla

Date Posted: July-14-2009 at 12:20pm

| Gotcha, that makes sense! From the picture when you put it in the boat it looks like you can see an edge that looks like glass. What am I seeing there? |

Posted By: hasbeenskier

Date Posted: July-14-2009 at 10:25pm

|

It is foam core that was glassed along the edges for a cleaner finished

look. Nida core is honey combed and not a very clean finish. I will have the pictures I promised in a few more days. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:03pm

|

Finally, the engine cradle is done. I went back to the post when I anticipated the cradle to be completed.... 12/09. I am glad I'm not under contract. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:11pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:13pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:18pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:21pm

|

While I have your attention. Gary's 79 BFN was shot with gel yesterday.Now it is going to sit several days then... sand and buff.

bj ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:22pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-24-2010 at 7:24pm

------------- hasbeenskier |

Posted By: akabulla

Date Posted: April-24-2010 at 11:33pm

| Glad to see you back at it! Looking good! |

Posted By: DrCC

Date Posted: April-25-2010 at 3:03pm

|

BJ, It is refreshing to see someone else still believes in original resin.

Note: On BJ's pics of lay-up, clear! No white, no air bubbles. AT |

Posted By: TRBenj

Date Posted: April-26-2010 at 2:19pm

|

BJ, looks great- as usual! Gary's '79 looks mint as well. Youre still a few steps ahead of us... our cradle needs some grinding and rewelding. ------------- |

Posted By: hasbeenskier

Date Posted: April-26-2010 at 6:57pm

|

Hey Tim, Thanks, It is a very slow process. It seems like everything else is a priority. Your project is helping me along. You and your dad have taken some large steps.

bj ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-28-2010 at 9:09pm

|

I spent the day working on the BFN mounted both fins, the drain plug,and the raw water through hull pick up. Gary built a stainless strap with two gussets at the top and mounted the transom lifting ring. Nothing ever moves fast, but it is moving.

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-28-2010 at 9:20pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-28-2010 at 9:22pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-28-2010 at 9:23pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: April-28-2010 at 9:31pm

|

For the sake of conversation the first of the three photos in this post show four green pieces of 2X4 channel on the stern's deck. They are fiberglass. I am going to glass them down, then mount the fuel tank down. There will be rubber between the mounts and the tank.

bj ------------- hasbeenskier |

Posted By: 8122pbrainard

Date Posted: April-28-2010 at 9:44pm

|

BJ,

That bracket will lift the Queen Mary!! Nice work. Now I sure Tim's doing some thinking on a new project!  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: hasbeenskier

Date Posted: April-28-2010 at 9:48pm

|

Thanks Pete, Coming from you it is like getting a blue ribbon!

bj ------------- hasbeenskier |

Posted By: Donald80SN

Date Posted: April-28-2010 at 9:50pm

|

BJ,

Very nice. This boat will outlive all of us. Donald |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 2:45am

|

Everything seems to take a priority over this boat but it does move forward from time to time. I thought I would revive the post for the amusement factor. Paint pictures to follow. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 3:48am

|

Have tried for one hour to post photo bucket updates and only can get a thumb nail picture to post? Any suggestions as to my errors. ------------- hasbeenskier |

Posted By: BuffaloBFN

Date Posted: August-05-2011 at 11:21am

|

Howdy BJ. Are you using the thumbnail code? The image code is the one you want. I'm looking forward to the pics. ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 1:02pm

|

Hey Greg it has been a long time. Got It. ------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 1:13pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 1:16pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 1:17pm

------------- hasbeenskier |

Posted By: hasbeenskier

Date Posted: August-05-2011 at 1:18pm

------------- hasbeenskier |

Posted By: Keeganino

Date Posted: August-05-2011 at 2:35pm

The gelcoat looks amazing!  ------------- "working on these old boats may not be cost effective but as it shows its what it brings into your life that matters" -Roger http://www.correctcraftfan.com/diaries/details.asp?ID=4897" rel="nofollow - 1973 Skier |

Posted By: Morfoot

Date Posted: August-07-2011 at 12:55pm

Nicely done BJ..Looks like I need to take that trip down there and see it person. Carry on my good man!   ------------- "Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman" |

hasbeenskier wrote:

hasbeenskier wrote: