Another BFN Rebuild

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=16014

Printed Date: April-01-2025 at 9:48pm

Topic: Another BFN Rebuild

Posted By: TRBenj

Subject: Another BFN Rebuild

Date Posted: December-09-2009 at 3:08pm

|

Things are starting to slow down a bit here with winter having set in and the holidays upon us... so hopefully this will spark a bit of interest. There have been several worthy BFN rebuild threads (Buffalo, Hasbeen, Grinch), but ours will have a few unique elements- so while I was initially hesitant to start a thread of our own, I guess theres no harm in doing so. So here goes- you might want to put on your reading glasses though.

A bit of background: This past summer I was able to convince my dad that a BFN would be a nice addition to our fleet. We found this '79 in New Hampshire, and while it was a little rough around the edges, it was largely complete. While I wouldnt call its performance during the test drive overly impressive (it was taking on water at a pretty good clip, it wouldnt come out of the hole to save its life, and one of the speedos leaked all over me the whole time), it did turn in an honest 52mph on the GPS- so we were sold. Over the last remaining months of summer, we tinkered with it a bit- tried a few props, added a DUI distributor and a 750cfm Holley, did a bit of rewiring and gauge replacement, put on a new starter, re-sealed the rudder port (and got a new rudder when we didnt safety wire the original back on), etc. We footed with it some and hot lapped the lake a bunch. It was reliable, the holeshot was much improved, and it turned in a best of 58.5mph in Lake George to win the 2009 "Adirondack Dash"... so not bad first summer.

What we knew going in was that any boat this age was going to need structural work at some point... and while all the motor mount lags were tight, the boat did come without a cover so it had been exposed to its fair share of weather. The only soft spots in the floor were in the rear removable panel and a little bit around the pylon- but we figured it was due sooner rather than later. The glass over the stringers in back had plenty of cracks as well. When we pulled the pylon out of its cup in the hull when using the boom (the floor flexed enough to allow this), that confirmed it... this winter it would get re-strung. So this is where the fun part begins. Dad has done most (all) of the hard work up to this point- having the boat in his garage makes it a bit easier, I suppose. He pulled the floor to find most of the wood to be rotten, no doubt helped along by a lot of waterlogged foam. The front section between the engine and bow were particularly soaked- the 3 vent hoses which had disintigrated and the faulty battery box drain were surely contributors. Dad said he easily removed 400 or so lbs of foam. These are the only decent pictures I have up to this point, along with the ones I shared in the "redneck engine hoist" thread:

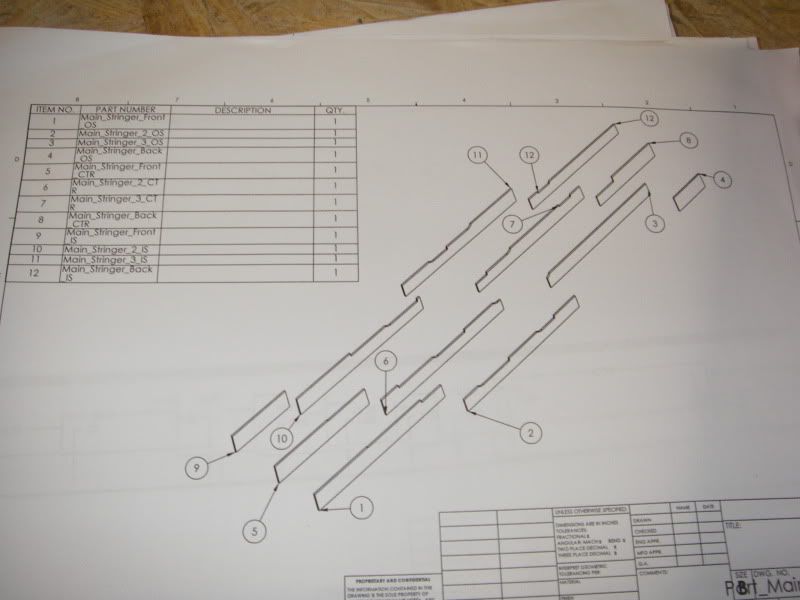

With the weight of the 454 and soaked foam gone, the trailer springs have breathed a sigh of relief! As it sits now, all of the stucture has been removed, save for one main stringer. Ive got a bit of grinding to do this weekend, and then it gets tucked into the back of the garage where we will start to put it back together. We've assembled a list of modifications and changes we want to make. These include: -replace all wood in floor and stringers with composite -install engine cradle -replace all flimsy vent tubes and hoses with PVC pipe -move pylon 2" forward to allow access to bilge in front of engine -install kick plate that spans half the width (like on newer boats) for more under bow storage -replace drivers seat frame with 80-84 (non-delux) version to allow easier adjustment We've also got some engine work planned and some cosmetic work to do, but Ill save those for another thread. Right now, the plan is to not refoam, at least not entirely. We may do a bit of the bow section to give the boat some floatation and hold all of our tubes/vents in place. Thanks to JoeinNY for that idea. Im also stealing a page from Joe's book with the stringer and floor material selection- Coosa. He's been a great help so far by cluing me in on some of the finer points of his construction.

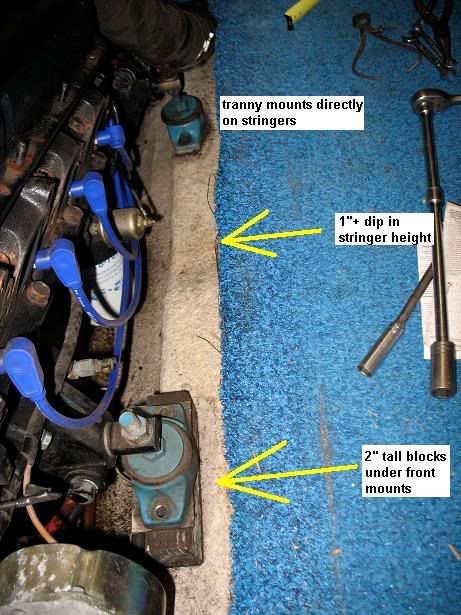

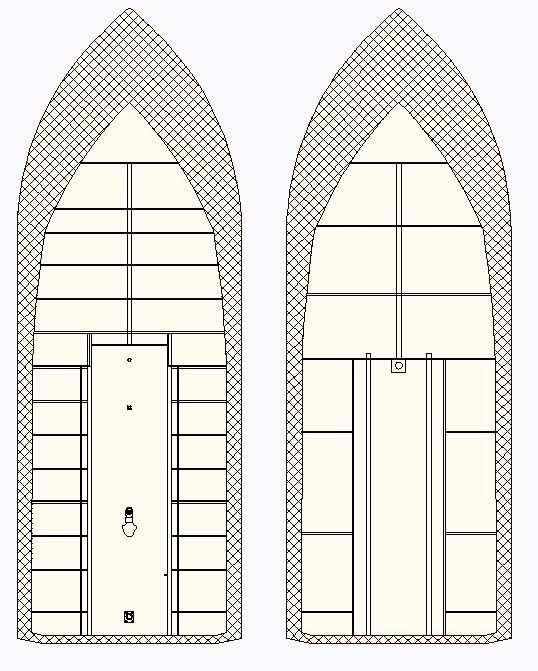

Before we start ordering materials, we're going to mock up all the pieces we'll need out of wood. That should give us an accurate idea of how much we'll need to buy. Probably a good idea since coosa isnt cheap. Right now I am planning the stringer layout in CAD- its probably the most fun Ive had with the tool yet. The biggest obstacle, if you want to call it that, is the addition of the engine cradle. The early BFN stringer shape doesnt lend itself very well to installing one- there is a ~1" jog in the stringer between the front and rear mounts. The rear OMC mount installs directly on the main stringer, while the front mounts sit on 2” tall blocks and shims. Even with secure lags, these blocks flexed a bit with the torque of the BBC, so they have to go.

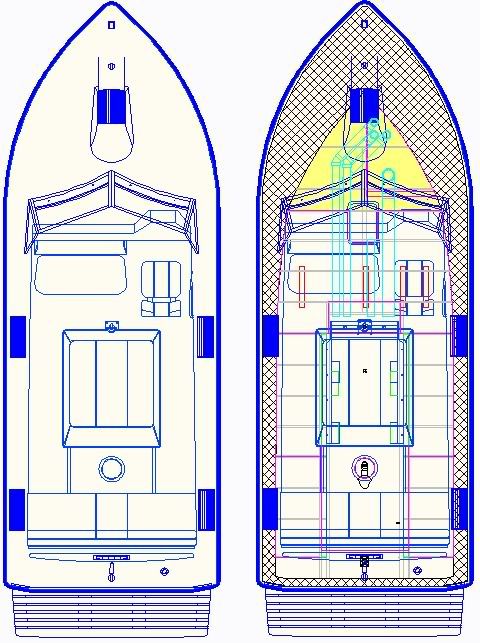

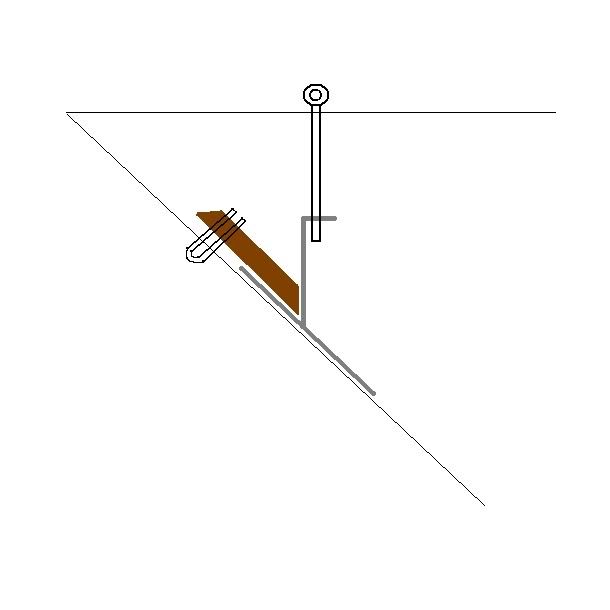

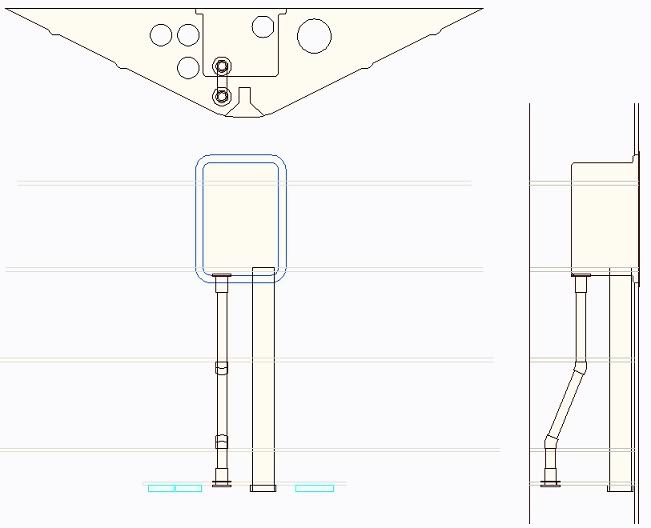

Since the stringer shape will need to be different (flat) regardless, Ive decided that the best option is to install a newer style engine cradle. Starting in 1990 with the Ski Nautique, newer CC cradles require wider primary stringers, by about 6” (inside to inside of 26” vs. 20”). Instead of the mounts sitting directly on the cradle and having the stringer notched below it to give space for the nuts to attach, the mounts sit inward on angle aluminum tabs that are welded to the cradle. Heres a visual from my ’90 SN:

Since installing a newer cradle will require cutting off and rewelding the tabs to accommodate the 454 anyways, this gives us a lot of flexibility on final stringer height. No need to be super precise with our layup since we control exactly where the mounts will be (both height and distance from transom) by where we locate our tabs on the cradle. Anyways, here is a quick look at the proposed vs. old structure:

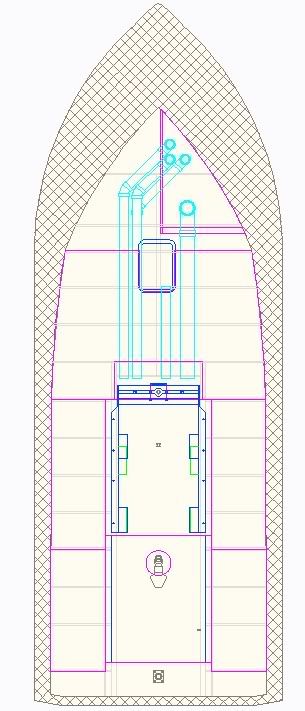

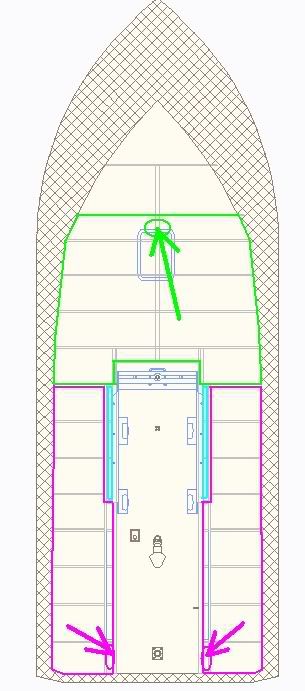

Its not finalized by any means, but its getting close. Here is what the structure will look like with the vents/tubes (teal), cradle/battery box (blue) and the floor (pink):

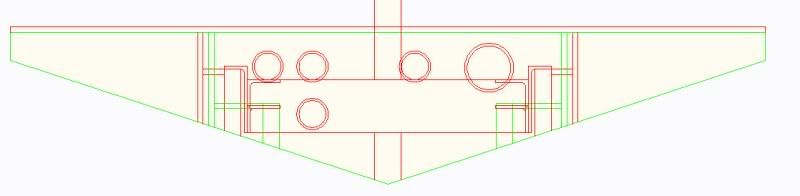

The plan right now is to foam in the front 3 cavities (up to the 3rd bulkhead). This is a (very) rough picture of what the cross section will look like (at the rearmost bulkhead). Old structure is in green, new in red.

Like I said, nothing is set in stone yet- still plenty of time to make changes or incorporate new ideas. Comments/questions/concerns are welcome! Ill get some updated pictures this weekend. |

Replies:

Posted By: M3Fan

Date Posted: December-09-2009 at 3:52pm

|

Wow. That is all. Wow. ------------- 2000 SN GT40 w/99 Graphics/Gel 2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

Posted By: 502Python

Date Posted: December-09-2009 at 5:09pm

|

I'll be watching this thread. Looks like there is a lot for me to learn from you. ------------- 1999 Sport Nautique-Python Powered 1999 Ski Nautique-Python Powered |

Posted By: 81nautique

Date Posted: December-09-2009 at 5:36pm

|

I think you should re-title the thread to "Not Just Another BFN Rebuild" ------------- You can’t change the wind but you can adjust your sails |

Posted By: TRBenj

Date Posted: December-09-2009 at 5:50pm

Ha, I dont know Alan- have you seen Gregs, BJ's and Kirk's work? Those are tough acts to follow! ------------- |

Posted By: M3Fan

Date Posted: December-09-2009 at 6:07pm

Well put. ------------- 2000 SN GT40 w/99 Graphics/Gel 2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

Posted By: 81nautique

Date Posted: December-09-2009 at 6:08pm

The bar is set pretty high indeed but that's whats so great about this site. You can see the quality of the rebuilds from year to year keep improving. We're turning out some very well done projects these days, not to put too much pressure on you.  ------------- You can’t change the wind but you can adjust your sails |

Posted By: Riley

Date Posted: December-09-2009 at 6:26pm

|

The other amazing part is that it will be completed by April. ------------- |

Posted By: TRBenj

Date Posted: December-09-2009 at 6:49pm

|

Very true Alan, lots of quality work going on around here these days. Hope we can keep that trend going!

Just for fun, heres the what the overhead view looks like with the top deck and accessories installed. I wasnt going to go this far, but knowing where the scoops, seats, dash and everything else are really helps lay out the structural pieces underneath. Of course, I probably got a little carried away with some of the details. Oh well.

Bruce, I dont know about April, though that would be nice. May-June would be acceptable. ------------- |

Posted By: Wacko

Date Posted: December-09-2009 at 7:21pm

| Looking forward to the updates. This looks very interesting and well thought out. |

Posted By: TRBenj

Date Posted: December-09-2009 at 7:54pm

|

Now that the ball is rolling, does anyone have any ideas on how to improve storage in the boat? While its a full 19', it really has no more storage than my 16' Skiers or Tique did- which is to say, next to none.

Right now Im thinking of adding another pod on the passenger side like Kirk (the Grinch) did.

Probably incorporate cupholders like he did, too. I have a black glove box out of a '68 Freeport- what did the 70's glove boxes look like, and where were they installed? Up under the dash? I dont plan on cutting any holes. What about the forward-folding observers seats in the 80-84 Ski Nautiques with non-delux interiors... does that make access under the bow that much easier, or are they useless? Under floor storage somewhere? BJ mentioned that he'll be moving his battery to the rear of his BFN. I considered that, but I think Ill need as much weight forward as I can get- with the extra 400 lbs of waterlogged foam in the bow, the boat still ran plenty bow high. It would really rise up when coming out of the hole with a few people in the back seat too- I dont want to make that worse with a rearward weight bias. For whatever reason, this BFN doesnt seem to run faster with extra weight in back like the smaller, flatter boats- so no worries there. What about future growth- anything I should consider adding now with the floor out? I have no plans for a heater, stereo, shower, etc- but who knows what the future holds. Again, I will not be cutting any holes in the dash or gunnels- in case that wasnt clear. ------------- |

Posted By: tullfooter

Date Posted: December-09-2009 at 8:01pm

|

Tim

Quit being so vague.

Have you gotten your cradle situation figured out? ------------- Play hard, life's not a trial run. '85 BFN '90 BFN White Lake, Michigan |

Posted By: TRBenj

Date Posted: December-09-2009 at 8:14pm

Ha, sorry Steve... too much detail? I think maybe its figured out- I havent spoken with him yet, but Eric is supposedly bringing them back to OH. Once I can confirm that, Ill let you know. Thanks again for your offer! ------------- |

Posted By: lewy2001

Date Posted: December-09-2009 at 8:49pm

|

Tim I think the engine cradle would be a must with that much torque. The stringers on your BFN are very different to Greg's latter model BFN. In his the engine was mounted on a cradle lower in the hull and the primary stringers were much lower than the secondary stringers that supported the floor.

It appears they put that dip in the stringer so the block under the front mount could be smaller. That is a bit "agricultural" (rough in Oz slang). When Correct Craft started using the cradle it was a huge improvement for engine to drive line stability and the pylon mount was much more substantial. By going to the wider spacing on the primary stringers. Would it be possible to do away with the secondary stringers assuming they are there only to support the foam filled floor. Then just use the full bulkheads before the engine and the half bulkheads down the sides and after the engine to support the Coosa floor. The beam on your BFN is a bit narrower than the latter BFN's that would lend it self to this style construction. This was how I have planned my stringer replacement in my 89 if I ever get the courage or inclination to pull the floor up. The 89 2001 also used the wider spaced stringers like your 90 as it had the PCM reduction tranny. Looking forward to following this thread as the bar is raised again. ------------- If you're going through hell, keep going http://www.correctcraftfan.com/diaries/details.asp?ID=2999" rel="nofollow - 89 Ski <a href="http://www.correctcraftfan.com/diaries/details.asp?ID=5685" ta |

Posted By: hasbeenskier

Date Posted: December-09-2009 at 9:11pm

|

I have two things to say

1) Atta baby! 2) Wooo hoo ! bj ------------- hasbeenskier |

Posted By: TRBenj

Date Posted: December-09-2009 at 9:34pm

|

Haha, thanks BJ.

Lewy, I like your idea about nixing the secondary stringers- I think Sebastian did the same thing. Unfortunately, it would be quite a stretch if its possible at all. Id have to see what the width of the BBC is at floor height- I think it might be too wide to fit in a 26" wide space. In other words, the stepped stringers open up enough to give it room and I dont think I could bring the main stringers full floor height. Even if the engine would fit, it would make it pretty hard to get a hand down into the bilge. Also, even with my taller mains (approx 3-1/8" taller than original), theyre still 3-3/8" below floor height. The new style cradle is 6-1/8" tall, which is driving the new height of my mains to avoid trimming it down. If I were to bring it up to the floor, the rear mounts would sit below the rails of the cradle- not ideal. Moreover, while the design would be simpler, Im not sure it would save any material... in fact it would probably cost more to make the 1.5" wide mains taller than it would be to just have the 1/2" wide secondaries in there (which are also shorter at less than 8'). Oh- and last but not least, the exhaust sits on top of the primaries so they couldnt be full floor height all the way to the back regardless (they'd block the thru-hulls). I guess that is a dealbreaker... but thanks for thinking outside the box! ------------- |

Posted By: SNobsessed

Date Posted: December-09-2009 at 9:34pm

|

Projects like this clearly mark this forum as the premier website for ski boats. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: TRBenj

Date Posted: December-09-2009 at 10:04pm

Ha, we havent even started rebuilding the boat yet... but thanks Chris. No argument on the quality of this website though- Im glad to be a part of it! ------------- |

Posted By: SNobsessed

Date Posted: December-09-2009 at 10:30pm

|

Tim - Your upfront planning will make a big difference in the end result, keep it up! ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: Keuka

Date Posted: December-10-2009 at 1:11am

|

Tim

With the attention to detail and preplanning you are doing before you even start, I can't imagine the finished project will be anything less than outstanding. I would just be tearing into it, taking lots of pictures and measurements along the way. I am a fairly new to this sight and have only been a boat owner since August. I am traveling a lot for work this winter been reading through these rebuild threads. It's great hotel reading and a little inspiration for the project I will someday face on my Martinique. Keep it coming David |

Posted By: lewy2001

Date Posted: December-10-2009 at 1:14am

When I looked at the picture at the start of this thread I thought the main stringer was at floor height. But now after looking more carefully I can visualise the step down. That is the same as in Greg's later model BFN. Just the angle that the picture was taken from made it look like floor height. Yes no secondaries just like the guy who did Kapla's stringer job and that is a much beamer boat than the early BFN. I feel if you are not going to re foam there would be no need for the secondaries. I don't think they add much to the hull strength but would like to hear what the engineers think of that. ------------- If you're going through hell, keep going http://www.correctcraftfan.com/diaries/details.asp?ID=2999" rel="nofollow - 89 Ski <a href="http://www.correctcraftfan.com/diaries/details.asp?ID=5685" ta |

Posted By: jbear

Date Posted: December-10-2009 at 2:02am

|

I gotta agree with Joel...wow...

john ------------- "Loud pipes save lives" AdamT sez "I'm Canadian and a beaver lover myself"... |

Posted By: TRBenj

Date Posted: December-10-2009 at 10:42am

Thats correct- the structure isnt exactly the same as the later BFN's, but its close. The addition of the cradle drove a few changes at the factory, as did moving the cockpit forward in '87. I agree that the secondaries dont add a lot of strength- ours were no more than 3/8" from the factory, maybe 1/4" (tough to tell since they were so rotten). They will essentially be framing the bilge in our construction. The engine just sits too low in the V-hull to bring the primaries full floor height, unfortunately. John, have you seen the '82 BFN project on ebay? Youve been playing that "not handy" card too long- I say you grab it and dig right in. You could borrow most of the ideas from my build for yours!  ------------- |

Posted By: Okie Boarder

Date Posted: December-10-2009 at 7:42pm

| Looking good so far. This is one I like to watch. I love the pre-planning and CAD work...very nice. The ideas you have seem really solid and well thought out too. |

Posted By: BuffaloBFN

Date Posted: December-11-2009 at 1:38pm

|

Glad you started this Tim; and looking good! ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: skfitz

Date Posted: December-11-2009 at 2:40pm

| Very impressive. What material do you intend to use for the stringers? Coosa sheet cut and laminated to proper dimension? |

Posted By: TRBenj

Date Posted: December-11-2009 at 3:19pm

Correct- the entire build will consist of coosa. The primaries will be 3 laminated layers of 1/2" bluewater 26. The rest of the ribs and bulkheads will primarily be 1/2", doubled at the floor joints as applicable. The front section of the floor where the front seats mount will be 3/4" with glass on both sides. The rest will likely be 1/2". The front sections that are being foamed will be simply glassed over, save for the raised kickpanel portion, which will be framed with 1/2" coosa to allow for the mounting of panels and accessories. ------------- |

Posted By: skfitz

Date Posted: December-11-2009 at 6:16pm

Could you 'splain for the noob? And by noob, I mean me. |

Posted By: TRBenj

Date Posted: December-11-2009 at 11:16pm

I will be doubling up the ribs/bulkheads (so they are 1" thick instead of 1/2") at all the joints in the floor. Clearer? ------------- |

Posted By: skfitz

Date Posted: December-12-2009 at 12:23am

| Got it. I'm looking forward to following your build. |

Posted By: BuffaloBFN

Date Posted: December-12-2009 at 12:08pm

Sounds like you'll pass Pete's crane dropping test.  ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: Hollywood

Date Posted: December-14-2009 at 2:18pm

I could have drawn that in MS Paint!

(in about 6 months) Just curious, but why are you running 3 tubes the "long" way and 1 the short way. Are they air/ventilation? Is the big tube for cables which you don't want to bend? ------------- |

Posted By: TRBenj

Date Posted: December-14-2009 at 2:25pm

Theres gonna be a test?! A few quick pictures I snapped after dad put in some good time with the grinder. A few more hours spent grinding next weekend should have it almost ready to start mocking up the new stringers and bulkheads.

All tucked in next to the 454!  ------------- |

Posted By: TRBenj

Date Posted: December-14-2009 at 2:32pm

Correct- the 3 tubes on the left are the vent tubes. The one on the right is for the steering cable, control cables, and wiring harness. I want the least number of bends in the cable conduit- Im less concerned with the vent tubes. If I could have fit all the tubes on the right, life would have been easier- but I want the battery box pretty close to centered for weight distribution and access reasons. Pushing the vent tube outlets as far towards the bow as I can has them exiting pretty close to a straight shot from holes in the deck, so minimal 3" hose lengths between them. ------------- |

Posted By: Hollywood

Date Posted: December-14-2009 at 2:39pm

|

The airbox is definitely usable space. I have a small amplifier sitting flat on our 88 SN. Leave room for a heater core, etc.? ------------- |

Posted By: TRBenj

Date Posted: December-14-2009 at 5:19pm

No plans right now for future growth, but Ive laid it out such the vent tubes are as far forward as possible, and the conduit tube is as far towards the rear as I can go without interfering with the kick plate panel. ------------- |

Posted By: kapla

Date Posted: December-14-2009 at 5:45pm

|

uff got some memories back..LOL..it will be a nice post to follow through the slow winter here in the site..LOL

as for custom desing in my floor its holding quite well till now...boat rides very stiff..... kapla ------------- <a href="">1992 ski nautique |

Posted By: Hollywood

Date Posted: December-14-2009 at 5:52pm

|

The boat needs some SKI NAUTIQUE decals, for sure. ------------- |

Posted By: lfskizzer

Date Posted: December-14-2009 at 9:50pm

|

Hollywood,

This is how I setup mine on the 85 ski, it is very difficult to get it all the way forward, but turned out pretty good i guess.

Sorry for the hijack Tim ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=4457 - 2008 Ski Nautique 206 http://www.correctcraftfan.com/diaries/details.asp?ID=2683 - 1985 Ski Nautique 2001 Series |

Posted By: 82 Nautique 1

Date Posted: December-23-2009 at 3:04am

|

Phil, How did you get the kick panel area foamed like that ? Did you form it in wood, pour the foam and then strip the wood ?

Will you then glass over it all ? Thanks for the information ------------- Original Owner " Dennis" http://www.correctcraftfan.com/diaries/details.asp?ID=4855" rel="nofollow - 1982 Nautique |

Posted By: TRBenj

Date Posted: December-31-2009 at 6:56pm

Well, I *think* the worst is over. We removed all the glass that held the original stringers, ribs and bulkheads in, and removed all the wood in the transom. About a dozen 24 grit flap discs later, final grinding is essentially done.

We've left the edge of the floor in place for a reference as we start to rebuild. It will be removed and final grinding on the walls will be done once the new pieces have been cut and test fit. ------------- |

Posted By: BuffaloBFN

Date Posted: December-31-2009 at 7:20pm

|

How bad was the ply in the transom?

Otherwise...

And braver than I! ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: Wacko

Date Posted: December-31-2009 at 7:23pm

| Looking good Tim. Keep the pics coming |

Posted By: TRBenj

Date Posted: January-01-2010 at 3:05pm

It wasnt crumbling, but definitely wet. That center piece was a bear to remove! The angle iron lifting ring mount was a tad questionable looking, so all the wood had to go. The front lifting ring mount still looks great so we havent touched it- but now Im thinking it might be a good idea to get every single last piece of wood out of the boat. Thoughts? ------------- |

Posted By: hasbeenskier

Date Posted: January-01-2010 at 3:26pm

|

Happy New Year Tim. I do not think my position needs expressing. The only wood in my boats are ply braces under the gunnels

bj p.s. those pics make me itch. ------------- hasbeenskier |

Posted By: TRBenj

Date Posted: January-01-2010 at 4:09pm

|

I hear you loud and clear, BJ! Id like to see all the gel in the bilge and transom go as well- just trying to figure out what is justified vs. overkill. Maybe Ive got a bit more grinding left to do... just when I finally stopped itching! ------------- |

Posted By: davidg

Date Posted: January-01-2010 at 6:03pm

|

Tim....Maybe you mentioned it previously and I missed it, but, were your stringers completely wet/rotted? If you didn't do this rebuild, could the boat have still been run safely with the stringers as they existed? I often wonder the condition of mine in the '76 Southwind.

By the way, very nice work! |

Posted By: hasbeenskier

Date Posted: January-01-2010 at 6:45pm

|

Roge' Captain, I chose to get all the gel off. I can say overkill is when you see the ground through the hole. I have also learned when you think you are through grinding....your not!

bj ------------- hasbeenskier |

Posted By: TRBenj

Date Posted: January-01-2010 at 7:12pm

|

BJ, what do you use for grinding? Even the recommended 24 grit flap discs dont last too long with the gel. Only one small break through on the transom so far... no holes in the hull yet!

David, all of the wood was wet. The secondary stringers and a lot of the ribs/bulkheads were rotten. There were several hundred pounds of wet foam in the front of the boat. The main stringers werent complete mush though- so I would guess the boat could have soldiered on for several more years, especially considering how hard we ran it this past summer. We still hadnt noticed any adverse signs of the rot- no gel cracking, etc. ------------- |

Posted By: Gary S

Date Posted: January-01-2010 at 7:19pm

Very easy to sit here Tim, warm and not itching and never having done this but personally if you have to question it you'll have to do it just to get it out of your head. Maybe someday you'll want to hang it from the rings and then you will not have to worry. I know, get your Dad to do it  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: BuffaloBFN

Date Posted: January-01-2010 at 7:54pm

|

Tim, the bow ring on mine didn't look to have any wood in its anchor. It was connected from the ring with a threaded rod down to the 'keel ring'(trailer ring) and into a stainless bracket that also held the keel ring. Not sure that's the name for it. It did have some 4x4 backers under the top ring; mine weren't bad so I soaked 'em in CPES and re-attached the screws from the top. It's solid now.

Only my opinion...I'd get the rest of that gel off and check the rudder port. I know you know that but had to say it.  ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: uk1979

Date Posted: January-02-2010 at 11:57am

|

Tim I can take some pictures of my SN front keel mount, I thought it would be toast as my boat had been used in the sea but was still in good shape only surface rust, I think it’s a judgement call as to how wet it was when you took the foam out around it on your BFN. ------------- Lets have a go 56 Starflite 77 SN 78 SN 80 BFN |

Posted By: eric lavine

Date Posted: January-02-2010 at 1:12pm

|

Ive been looking into Kingplastics.com, and can see many uses for the stuff, i have some smaller samples, it would really be nice to make the floor with the non-skid 1/2, i never thought about ballast tanks made from the plastic, its weldable and maybe someone has experience with welding it.

looks like next Saturday i"ll be buzzing up to detroit for the cradles and hulls, we got 8" on the ground today and still coming ------------- "the things you own will start to own you" |

Posted By: davidg

Date Posted: January-02-2010 at 1:15pm

Interesting that the wet foam was toward the front of the boat. My boat seems to sit "stern high" in the water when empty, almost to the point of almost having the rear chines slightly above the water line. Maybe thats just the way Southwind's sit in the water, but, I am now wondering if it could be due to the wet foam being toward the front??. Also, Tim, I see you took out both stringers at the same time. I had read before that some people note that their hulls "distort" in shape when they take both stringers out at the same time. Did you notice that, or did you take precautions to keep that from happening? |

Posted By: WakeSlayer

Date Posted: January-02-2010 at 1:37pm

|

I wish my SN hull looked like that right now. That looks great!!

I really need a Saturday above freezing so I can do it outside. I have the same question as David. I would prefer to cut all the stringers out, then grind it all at once. I plan to support the boat off the trailer and do them one at a time. I will have to do a little grinding indoors then. If you cut them all out at once, and presumeably moved the boat outside to grind, how do you know you got the boat back to the same shape when you support it? ------------- Mike N 1968 Mustang |

Posted By: TRBenj

Date Posted: January-02-2010 at 3:25pm

|

Eric, good deal! The more I think about it, the nicer it would be to have the cradle in hand before we start rebuilding- so I may have you ship them to me if thats OK. Thanks again, by the way.

Gary, I hear you- but the thing is that the front lifting ring doesnt look to be mounted to any wood, and the metal thats bedded into the hull looks great. Theres no question its solid. There is a hump behind the bow eye that Im guessing has wood in it though... but Im not 100% sure. I think Ill snap a picture to see what everyone thinks. The foam closest to the floor was relatively dry, Roger- so thats another clue that we may be OK. Of course, the transom wood was wet, and there was no foam to blame for that! Greg, I may spend a little more time with the grinder today and get the remaining gel off- at least that in the keel. Your rudder port was mounted on a wood base, wasnt it? We had our port apart this past summer to re-seal and Dad swears ours is all glass. With all the 5200 we used putting it back together, Im dreading taking it apart again. Maybe Ill grind a bit to see if I hit any wood. David, the boat sat ass-high in the water last summer- lots of light under the platform, which you can see in my first post on this thread. Allegedly the BFN was born from the Southwind hull, so Im not sure yours should be much different. The front part of the v-hull is obviously the lowest part of the boat, so it collected the most water. Like I mentioned previously, the most obvious contributors were the failed battery box drains and air vent hoses. Mike and David- you caught us... we decided not to take any precautions to brace the hull with the stringers removed. We've kept it on the trailer and keep wheeling it in and out of the garage to do the grinding. I have to say that the hull remainded very rigid, right up until we removed the glass that had been used to attach the stringers and ribs. Now it will oilcan slightly underfoot when working inside. Im not too worried about the v-hull flexing front to back, though, and the trailer supports are pretty wide, so side to side flexing shouldnt be much of a factor either. We'll find out if we made the right call once we get it back on the water! ------------- |

Posted By: WakeSlayer

Date Posted: January-02-2010 at 3:34pm

|

Tim,

Being as you also have the same boat I am about to dig into, do you believe that would be a safe move with that? I have an original trailer under it, but it is pretty beaten up and I am not sure the bunks are perfectly straight. Just thinking out loud here. If I were to approach it that way, I would probably jack the boat up with the stringers level both directions, then see where the other parts of the boat sit level/angle wise. Then drop it down to remove the wood, take it outside, have a flap disk party, and then jack it back up to the same angle etc as it was. Does that make sense to attempt? I see myself having to grind a bit in my shop if not, and I REALLY do NOT want to do that at all. I have a couple weeks before the Mustang leaves for a month. I would like to get the stringers replaced in that period. ------------- Mike N 1968 Mustang |

Posted By: TRBenj

Date Posted: January-02-2010 at 3:41pm

|

Mike, the secondary stringers are out of my '67 and the primaries are still in... the hull doesnt noticeably flex when walking in it. The hull didnt flex a bit on my Tique when I had the stringers out (I didnt support that either), so Im inclined to say that the older, smaller boats dont need the extra support. The narrow beam and thick layup allows the hull to maintain its shape, even with the stringers out. ------------- |

Posted By: SNobsessed

Date Posted: January-02-2010 at 9:09pm

|

Mike - Maybe you could make a X shaped frame gage out of 2x6s so you can judge if it warped from removing both main stringers. Then you would have a known reference. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: eric lavine

Date Posted: January-03-2010 at 1:08pm

|

i would bet CC doesnt lay the hull in a jig when they set the stringers and probably do close to the same as weve seen on many rebuilds, you are starting fresh again and everthing is custom to its final resting place, such as the engine and cradle...the boat isnt aligning it, you are. i really dont think it is a big concern, but obviously you do want some support under there as a good starting point ------------- "the things you own will start to own you" |

Posted By: Okie Boarder

Date Posted: January-03-2010 at 3:21pm

| Looking good! You're progressing a lot faster than me. |

Posted By: WakeSlayer

Date Posted: January-03-2010 at 3:44pm

|

Cool. I may give that a go. I have a couple weeks to think about it. ------------- Mike N 1968 Mustang |

Posted By: TRBenj

Date Posted: January-04-2010 at 2:45pm

|

Okie, not really- we've been underway since early November and we havent ordered any materials yet... youre moving much faster than us!

I would like to officially thank Greg, Gary and BJ on making me itch for another 3 days. And for almost giving me frostbite. It was a balmy 9 degrees in CT yesterday- but now I can say that the grinding is done. All wood (save for the aforementioned gunnel braces) is out of the boat- including the bow eye backer and the rudder port mount. Getting the rudder port out that had been sealed with 5200 this past summer wasnt as bad as I thought it would be- a little heat and a BFH did the job. Out in the cold:

Is that dust or snow? A bit of both!

A thorough rinse with hot water created the Ice Nautique:

All the gel is off the hull and transom (still a little icy though):

The rudder port mount:

The front lifting ring area:

All tucked in across the back of the garage:

I need to confirm a few more vertical dimensions next weekend, then we can put together a decent material list and get some glass and coosa on order. ------------- |

Posted By: Wacko

Date Posted: January-04-2010 at 2:58pm

| Looking great. Excellent progress considering the weather conditions |

Posted By: Gary S

Date Posted: January-04-2010 at 4:47pm

|

Awesome Tim. I didn't realize thats how the lift eye mounts but now you'll never have to think about any old wood again. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: Hollywood

Date Posted: January-04-2010 at 4:55pm

|

I like how Tim is standing back taking the photos and the old man is doing the work again (remember the engine pull). ------------- |

Posted By: M3Fan

Date Posted: January-04-2010 at 5:01pm

|

What kind of regular expeditions/trips are you doing to facilitate DUAL cargo carriers in addition to the hauling capability of the truck? I mean honestly! ------------- 2000 SN GT40 w/99 Graphics/Gel 2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

Posted By: TRBenj

Date Posted: January-04-2010 at 5:22pm

|

Gary, in case my pictures dont illustrate it well, here are a few more.

From Roger (UK):

A crappy diagram using paint:

Im not sure if Roger's did or not, but the wood backing block for the bow eye extended all the way to the vertical steel portion of the lifting ring assembly on our BFN. Joel, you'd be surprised how often I use the roof boxes. I keep saying that Im going to remove them between ski seasons (I keep both snow and waterski gear up there) but I keep finding uses for them, even in the off seasons (the latest being a set of cornhole boards I built as an xmas present). Its really handy not to have to fold down the seats every time I want to move something more than a few feet long. The smaller box gets used less than the big one, but its already up there and Im already taking the aerodynamic hit, so I figure what the hell. Splitting my time between 2 states ensures that my truck is always full of gear. ------------- |

Posted By: Gary S

Date Posted: January-04-2010 at 5:51pm

|

That makes it clear Tim. What was that piece of wood for in the center of the transom? Is it for the lift ring?

------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: TRBenj

Date Posted: January-04-2010 at 6:17pm

Gary, thats correct. The wood was actually doubled up under the piece of angle iron... and boy, was it fun removing that piece of wood. Here's the best picture I have of the original assembly:

------------- |

Posted By: Gary S

Date Posted: January-04-2010 at 10:47pm

. Joel, he's got too many boats filling the garage he needs someplace to store stuff ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: RainDog

Date Posted: January-05-2010 at 12:43am

|

Tim - What is the significance of removing all the gel from the interior of the hull? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1868&sort=&pagenum=1 - 62 Classic http://www.correctcraftfan.com/diaries/details.asp?ID=5242&sort=&pagenum=1 - 2002 Super Air |

Posted By: Cslaten33

Date Posted: January-05-2010 at 12:48am

|

What should the top speed for a 74SN Skier be? ------------- Thanks Clark Slaten |

Posted By: Gary S

Date Posted: January-05-2010 at 1:50am

|

Steve I think you need to do that to get a good bond. Gel is only cosmetic,plus you know Tim,by the time he's done, the bilge will be as nice as the outside. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: TRBenj

Date Posted: January-05-2010 at 12:54pm

|

Steve, Gary is correct- you dont want to lay glass on top of the old gel. Theres no strength in it- Ive noticed its fairly brittle. Glass to glass will make a superior bond. Greg and BJ both laid fresh glass down over the hull- we may do the same in certain areas. Removing all the gel gives us unlimited options.

Clark, this isnt really the place to be asking the question, but first you need to fill us in on what youve got. I have no idea what a "SN Skier" is. Is it a Ski Nautique or a Skier? It cant be both. Which engine it has, prop, etc will all play a factor in its top speed as well. ------------- |

Posted By: Mark Mel

Date Posted: January-05-2010 at 2:15pm

|

Wow looks great Tim.

I use white glue to get fiberglass out of my hands. Spread on a layer, let it dry, then do another layer, let that dry. Then peel it off. It will pull most of the fiberglass out of your hands. You could do the same on your arms too, although that will pull the fur out too. You could also use duct tape although sometimes that pulls skin too. ;) ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=972&sort=&pagenum=4&yrstart=1976&yrend=1980" rel="nofollow - 1978 Nautique FBook - www.facebook.com/charliedontsurfct |

Posted By: TRBenj

Date Posted: January-05-2010 at 2:18pm

Thanks Mark! Are you talking like Elmers glue? Cool trick. Can I use it on my face?  ------------- |

Posted By: Hollywood

Date Posted: January-05-2010 at 2:20pm

Tim, I've got just the thing for your face.

Mark, he gets a parafin wax at his weekly salon visits, itch should be gone by Friday. ------------- |

Posted By: Mark Mel

Date Posted: January-05-2010 at 2:23pm

|

Yeah Elmers, I tried titebond once but it doesn't peel off as nice.

If I had a ton in my face I'd try it, lol. The face puts up with shaving every day so a little glue can't hurt. I should market it as a mask for men. ha Imagine Melissa's face when she sees you smearing glue on your face. "Mark Mel told me to do it - I knew he was a little off" ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=972&sort=&pagenum=4&yrstart=1976&yrend=1980" rel="nofollow - 1978 Nautique FBook - www.facebook.com/charliedontsurfct |

Posted By: BuffaloBFN

Date Posted: January-06-2010 at 12:07pm

Glad to throw in my 33 cents worth!

Looks great! ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: TRBenj

Date Posted: January-13-2010 at 9:10pm

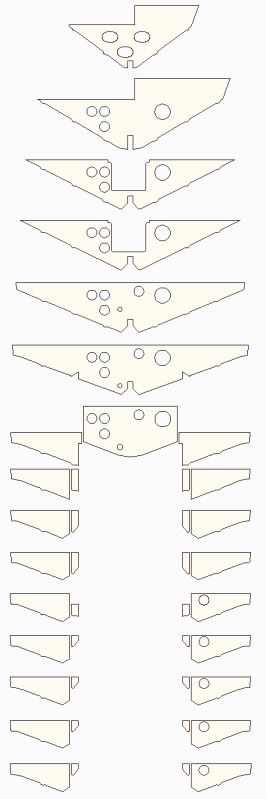

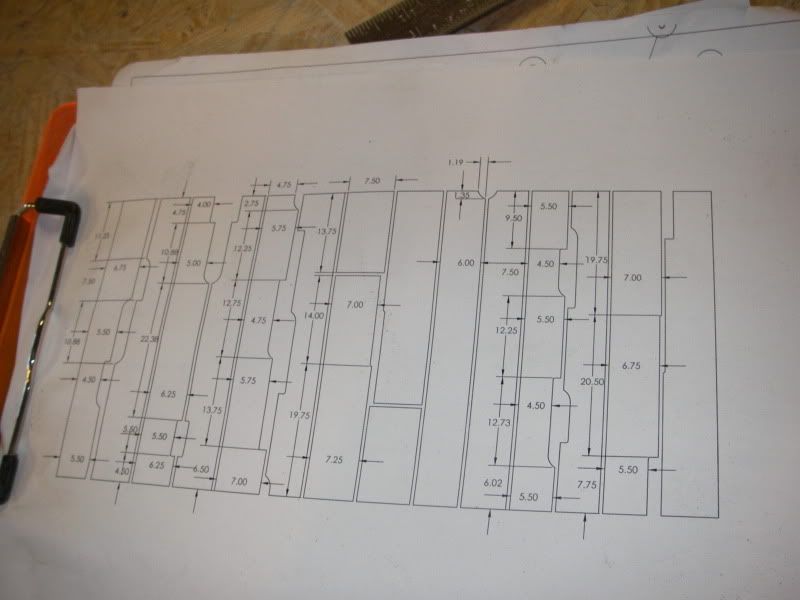

I took some depth measurements this weekend so I was able to lay out a rough cross section for the ribs and bulkheads. Not much holding us back from ordering materials now.

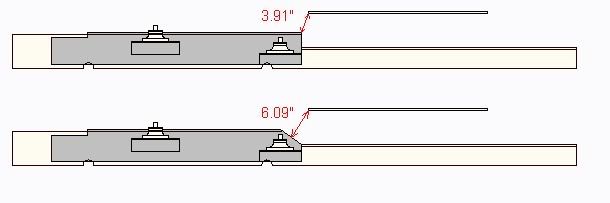

When I did the cross section of the stringers, I realized that with the taller primaries required by the new engine cradle (without cutting it up, anyways), I realized that the exhaust hoses wouldnt fit between them and the floor if left full height over their entire length. So, I cut them down behind the engine to closer to stock level. No need to waste material there anyways, I suppose. In order to clear where the exhaust hoses enter the bilge, I think the stringers and cradle will have to be notched at the top. The plan is to run 4" hose.

I also have a plan for the battery box drain. Im not crazy about having clamped connections below the floor, so I want to use PVC here as well. A few 22 degree elbows installed between the middle bulkheads should give me some slope so that it self drains.

We've come to the conclusion that no matter what, its almost inevitable that water will find its way under the floor- superior construction techniques and all. Therefore, Im leaving provisions to get the water back out. Like many here have done in the past (namely Joe in his '83), the under floor area will drain together via cut outs in the ribs where they join the secondaries. The front bulkheads will have notches where they join the keel board. Right now, the only compartments that self drain (to the bilge) are the ones on either side of the engine (note the half moon drains in the primaries). Since we want to through bolt the cradle instead of lagging it, the floor over the primaries cant be installed until after the cradle is in- so getting them sealed off from the top would be problematic. Everything else is sealed off from these, and there are 3 strategically placed access points to drain the subfloor area, should water ever get in. There will be no floor from the rearmost ribs back (essentially the last 10", under the gas tank), so any water in these 2 rear cavities can be reached with a pump if the nose of the boat is raised. To remove any water that collects at the low point of the hull in front, a 6" port will be installed on the front wall of the battery box. Right now, I think the access hole will be capped with an inspection plate similar to the one used over the driveshaft packing nut. ------------- |

Posted By: Mark Mel

Date Posted: January-13-2010 at 10:27pm

|

Are you going to CNC those bulkheads/ribs? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=972&sort=&pagenum=4&yrstart=1976&yrend=1980" rel="nofollow - 1978 Nautique FBook - www.facebook.com/charliedontsurfct |

Posted By: TRBenj

Date Posted: January-13-2010 at 10:33pm

|

I wish! No, each piece of the structure will be cut by hand... the hull is far from consistent so there will be small variations everywhere to get the final product straight and level. ------------- |

Posted By: Keuka

Date Posted: January-13-2010 at 10:36pm

|

Tim

To help with the water draining, would it be beneficial to add a drain plug on the low point in the center of the transom? It looks like you are planning relief cuts to allow the water to run all the way back. David |

Posted By: TRBenj

Date Posted: January-13-2010 at 11:08pm

David, thanks for the thought. The idea is to give the water a way out, without giving it an obvious way in. This is why Im keeping everything seperate from the bilge, for the most part. The manual drain points would be here:

The 2 rear side cavities (purple) drain to the back (but not to the bilge). The front cavity (green) will be collected at the low point in front of the battery box. The light blue areas will drain to the bilge. The front 2 cavities will be foamed (to hold the pipes in place and give me a little time before the boat goes to the bottom of the lake) and will be sealed off. I suppose I could put drain plugs in the bottom or transom in those 3 locations, but I dont think its necessary. Not much water should collect below the floor, so draining these cavities shouldnt be a regular occurance... more like a fail safe. Im thinking once or twice a year. For those times, a hand pump should work just fine. Im not too crazy about having to drill extra holes in the boat either! ------------- |

Posted By: Keeganino

Date Posted: January-13-2010 at 11:34pm

These diagrams are great, but since I am new to this could you please explain the holes in the bulkheads? Why it goes from three big ones to down to the end where there are 4 on the left and 2 on the right... I know this is probably common knowledge to all yall salty dawgs but it would help me understand the flow and layout. Thanks Keegan |

Posted By: RainDog

Date Posted: January-14-2010 at 12:11am

|

Tim, You should really consider planning out your projects instead of hacking into it with out thinking it through... ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1868&sort=&pagenum=1 - 62 Classic http://www.correctcraftfan.com/diaries/details.asp?ID=5242&sort=&pagenum=1 - 2002 Super Air |

Posted By: JoeinNY

Date Posted: January-14-2010 at 1:28am

At prices around 250 for a 4x8 sheet, you don't want to just start cutting that coosa without a plan...

Coosa first claimed they would CNC cut the pieces for me... then backed out.. too bad it would have saved a lot of cutting. Tim I ended up using a Jigsaw for most of the cutting to keep the dust at a minimum. I started off thinking a Zip saw would be the ticket but it was more trouble that it was worth even after acquiring various guides it was not easy to ever get a straight line, and it generated more dust. I went through a good sized pack of assorted dewalt jig saw blades, the coosa was surprisingly hard on them. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: critter

Date Posted: January-14-2010 at 1:38am

|

Joe, what about a 4 1/2" grinder with a cutoff wheel in it ? Would that cut about as good as a jigsaw ? It should be faster and then use a jigsaw on the inside corners. ------------- 1980 Ski Nautique 1966 Barracuda |

Posted By: lfskizzer

Date Posted: January-14-2010 at 2:06am

|

when we cut out our pieces for the stringers we used a table saw to rip the boards, sistered them up 1/2" 3/4" and 1/2" switching back and forth 5' 1" and 8' either or to get 13'1" for the Mains, then we traced them with the original stringers and jig sawed them. Then we used a planner to put the angles to somewhat match up to the hull.

critter a grinder would create alot of dust. with the table saw we attached a vacuum to the shoot out so the dust was to a minimal. Hey Tim you guys working on the boat this weekend? I might be bored saturday lol as im not going to VT this weekend. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=4457 - 2008 Ski Nautique 206 http://www.correctcraftfan.com/diaries/details.asp?ID=2683 - 1985 Ski Nautique 2001 Series |

Posted By: BuffaloBFN

Date Posted: January-14-2010 at 8:50am

There won't be any room for water under the floor with that layout! You could build a form around the bilge and pour in concrete; seems quicker.  ------------- http://correctcraftfan.com/diaries/details.asp?ID=2331&sort=&pagenum=12&yrstart=1986&yrend=1990" rel="nofollow - 1988 BFN-sold "It's a Livin' Thing...What a Terrible Thing to Lose" ELO |

Posted By: Morfoot

Date Posted: January-14-2010 at 9:50am

|

Guy's, have you tried a Diamond cut jigsaw blade. I use one all the time here at work to cut layered fiberglass that is a 1/4" thick or more with no problem. We also use it to cut A/C flooring in the cabin that is aluminum honeycomb core sandwiched between fiberglass. It's about 3/8" thick and the blade goes through that too. ------------- "Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman" |

Posted By: SNobsessed

Date Posted: January-14-2010 at 10:19am

|

Tim - It looks like you have all your bases covered.

I have a 3/4 hole cut into the bottom of my battery box & I have used it to pull water out too. There is about 1/2 inch of space between the battery box & the hull - I got about 6 ounces of water out of that area during winterizing. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: 8122pbrainard

Date Posted: January-14-2010 at 11:02am

|

Keegan,

Instead of trying to explain Tim's drawings, I feel looking at some pictures would give you a better idea. Start at about page 18 of Gregs http://www.correctcraftfan.com/forum/forum_posts.asp?TID=9543&KW=weeding+pumpkin+patch&PID=97043&title=span-classhighlightweeding-span-the-span-classhighlightpumpkin-span-span-classhighlightpatch-span#97043 - weeding the pumpkin patch thread. You'll get a good idea of where the parts fit plus the reason fo the different shapes. EDIT: Start on page 17 as it has some good pictures before Greg started putting in some of the floorboards. Here's a better link http://www.correctcraftfan.com/forum/forum_posts.asp?TID=9543&KW=weeding+pumpkin+patch&PN=17&title=weeding-the-pumpkin-patch - directly to the page ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TRBenj

Date Posted: January-14-2010 at 12:46pm

|

Keegan, in the front bulkheads, the 3 holes on the left are for the vent tubes. They exit the floor all the way at the front and attach to the scoop in the deck with 3" dryer tubes. The small hole in the middle is the battery box drain. The 3" hole in the middle is the tube for the battery cables. The larger hole on the right is the conduit for the steering cable, control cables, wiring harness, etc. The holes in the starboard rear ribs are for the blower line. All will be PVC.

Joe, you did all your cutting with a jigsaw? Geez, that sounds like a lot of work. I was thinking either a tablesaw or circular saw for the long straight runs. A jigsaw on the smaller, more intricate pieces definitely makes sense. Maybe diamond blades for whatever we use is a good idea. Greg, concrete- why didnt I think of that! Phil, probably no real work will be done on the boat this weekend- at least physical work. I need to put together a material list and get coosa and fiberglass on order. Not much going on until I have those in hand. If I have some time, I may do some investigating with the engine- but thats fairly low on the list of priorities for the short term. I just bought a cottage, so Ive got some other projects that need attention! Steve, Ill try to get my act together... sorry!  ------------- |

Posted By: 8122pbrainard

Date Posted: January-14-2010 at 12:58pm

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TRBenj

Date Posted: January-14-2010 at 1:03pm

Pete, as much as I would love one, I think a bandsaw is probably beyond our budget for this project. Ill invest in one eventually! Until then, Ill just keep hacking these things together.  ------------- |

Posted By: 81nautique

Date Posted: January-14-2010 at 1:06pm

|

Tim,

Are your drawings accurate enough to actually cut from or are they for a Bill of materials? How do you plan to transfer the dimensions to your stock? Do you have access to a plotter so you could make full size patterns or do you have to transfer everything by hand. ------------- You can’t change the wind but you can adjust your sails |

Posted By: WakeSlayer

Date Posted: January-14-2010 at 1:11pm

Hmmm. Not sure I am buying that reasoning, Tim. A bandsaw only costs half a Hitek. ------------- Mike N 1968 Mustang |

Posted By: 81nautique

Date Posted: January-14-2010 at 1:11pm

|

"We don't need no stinkin bad saw" That would be too easy. Only stationary tool I have is my table saw.

If you don't have a good jigsaw I can recommend http://www.dewalt.com/us/products/tool_detail.asp?productID=8993 - this one , I bought myself this one for xmas and it is an amazing tool. ------------- You can’t change the wind but you can adjust your sails |

81nautique wrote:

81nautique wrote: