96 ski nautique floor removal....help/ideas/tips!!

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=31778

Printed Date: November-17-2024 at 7:31pm

Topic: 96 ski nautique floor removal....help/ideas/tips!!

Posted By: sstewart

Subject: 96 ski nautique floor removal....help/ideas/tips!!

Date Posted: October-12-2013 at 3:09pm

| I have a 96 ski nautique that is full of wet foam. I have been reading the posts on the site for help but still have questions. How do I remove the driver seat base...it looks like it's fibreglassed into the floor, is this correct or are there hidden bolts? Is there foam under the air box area, any tips on best way to access this. Can I get under the cooler box and battery box without cutting them out, i'm tired of hitting stringers as I guess where they might be. If I have to remove them, is there a proper way to do this so I don't do unwanted damage. I appreciate any help as this is a crappy job. Also, where are the most common spots to look for how all this water is getting in.....one of my tracking fins was replaced and when I removed screws water poured out but can't believe that's the only way the water reached every compartment of foam. Finally, how many of you didn't put back the foam????? I appreciate any help as this is a crappy job and I am just winging it. |

Replies:

Posted By: jcocagne

Date Posted: October-12-2013 at 4:34pm

| I would also like to know this for our 94' SNOB. Getting new carpet and would like to remove the seat base. |

Posted By: 8122pbrainard

Date Posted: October-12-2013 at 7:42pm

|

Scott, Keep reading!  There are plenty of threads that cover the complete water in the foam/stringer issues. The most common water intrusion is simply from wet people getting into the boat. Of course this is without hull leaks. There are plenty of threads that cover the complete water in the foam/stringer issues. The most common water intrusion is simply from wet people getting into the boat. Of course this is without hull leaks.Regarding the seat base, it should be just screwed to the floor. Aren't there screws you can see? How about some pictures? Speaking about pictures, have you made a diary entry? We would like to see every CC made in that section! ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: jcocagne

Date Posted: October-18-2013 at 11:47am

|

This is from our 94'. i think the 96' might be the same. I cannot find any screws/bolts on the outside or on the inside. Is it fiber-glassed into the deck with a flange to tuck the carpet into? |

Posted By: TRBenj

Date Posted: October-18-2013 at 12:57pm

|

That black piece is in fact a shroud that covers the "real" pedestal that is glassed into the floor. Scroll through the pictures of the CCF boat at the top of the page and you'll see how the boats were built starting in '93. I am not sure how the shroud is removed- but it might just be held down by the seat tracks (which surely through bolt to the fiberglass pedestal. Pop the cover off that black bulkhead and you'll gain access to the underside of the bolts for the tracks. Scott, you may want to start a new thread to discuss what youre attempting to do with the boat. It should generate a lot of interest. A post entitled "drivers seat" is much less likely to gain attention than one called "removing floor and foam from a 93+ composite boat" or something similar. |

Posted By: Hollywood

Date Posted: October-18-2013 at 3:29pm

|

I would strongly consider buying another '96 in need of parts you already have from your current boat instead of doing this, unless you just need a project. You'll likely come out upside down financially. What you propose to do has not been documented, that we know of. ------------- |

Posted By: Gary S

Date Posted: October-18-2013 at 3:46pm

|

The only thing remotely similar I can remember would be Kevin Roundhill cutting his donor boat up ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: Hollywood

Date Posted: October-18-2013 at 3:53pm

|

eric lavine is/was cutting into a composite NWZ boat as well but hasn't been around or updated anyone on his progress that I know of. ------------- |

Posted By: jcocagne

Date Posted: October-18-2013 at 4:18pm

|

Excellent, that did the trick. Track bolts and access panel screws removed and the flange comes right off. A couple pictures just in case anyone wants to see. Thanks |

Posted By: sstewart

Date Posted: October-18-2013 at 9:18pm

| Well, thanks guys for the help and yes, now that I have started....I wish I didn't, it's extremely time consuming. Not happy that the seat is glassed in as well. I might just leave it in place and try to pull foam out from the sides. I will also change the title to see if anyone has any more tips. |

Posted By: Gary S

Date Posted: October-18-2013 at 10:04pm

|

Look up member KRoundy and pm him. Maybe he has not seen this post but he cut up a composite boat near to your year,he had pictures and might be able to give you some insight as to how they are built. He is the person I refered to above. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: Frankenotter

Date Posted: October-19-2013 at 10:02am

|

How do you know your foam is wet? Is the boat riding low? Chris ------------- 1999 Ski Nautique 196 |

Posted By: sstewart

Date Posted: October-19-2013 at 10:35am

| The bow always felt low, the floor felt like it was sloping downhill towards the bow, and I wasn't really happy with the wake. Something else I noticed and may or may not be related is the exhaust noise seemed high at idle which seemed to be due to it sitting above the waterline. The previous owner was also a bit neglectful regarding covering the boat, and the bilge often has a level in it. All gave me reason to believe she was wet down below ;) |

Posted By: sstewart

Date Posted: October-20-2013 at 6:08pm

| Thank you Gary S!....I read a little on KRoundy's posts and am going to pm him. |

Posted By: TRBenj

Date Posted: October-21-2013 at 10:16am

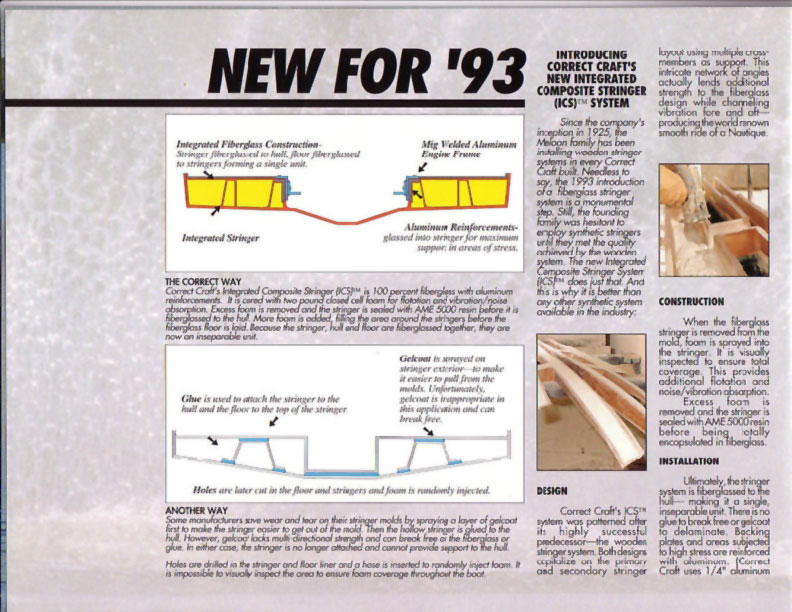

Have you looked at the '93 brochure in the reference section? There are some small pictures showing the new composite stringer system.  I am curious what the floor cross section looks like between the motorbox and battery box, as that spans the bilge and represents the piece that was previously wood in the earlier boats. I would imagine the remainder of the floor is very similar in construction (fiberglass over foam). Hopefully you have read some good stringer rebuild threads on here to get a taste for what is involved with this project. The bad news is that its a messy, time consuming job. The good news is that you wont have to touch the stringers- only remove the floor and foam, add a few structural members, and put it back together. It should go without saying that the motor should be pulled, along with as much of the stuff in the bilge as possible (wiring, cables, etc) as it will be a real nightmare glassing the floor back in with them in place. Same goes for the carpet on the walls- it'll need to come off. Get some pictures posted so we can see your progress and make suggestions on your course of action! |

Posted By: SNobsessed

Date Posted: October-21-2013 at 12:34pm

|

I would drill some small holes in inconspicuous places (i.e. under seat frames) & poke a wood dowel down into the foam to verify the moisture problem before tearing it apart. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: TRBenj

Date Posted: October-21-2013 at 1:01pm

From PN:

|

Posted By: quinner

Date Posted: October-21-2013 at 3:05pm

|

Looking at the section thru the floor there appears to be (2) stringers, one adjacent to the bilge where the engine cradle would attach and another where the wooden secondary is typically located. Reading the assembly description would lead me to believe there is no foam in the stringer cavity, what do you guy's think?? If there is foam what a PITA it will be to get at it. |

Posted By: TRBenj

Date Posted: October-21-2013 at 3:26pm

Hukt on Fonicks werked fir mee. |

Posted By: TRBenj

Date Posted: October-21-2013 at 3:30pm

| I would not worry about removing the foam from inside the stringers. Its not in the same cavity, so less likely to have become waterlogged... and even if it is wet, its not adding an appreciable amount of weight compared to all of the other foam. Its still providing enough strength to the stringer even if soaked, and isnt in danger of rotting anything out... so just leave it. |

Posted By: quinner

Date Posted: October-21-2013 at 3:55pm

|

Ah yes thanks Timmy, always been suspect of the effectiveness of my Evelyn Wood speed reading training!! Leaving the stringer foam alone or not was where I was headed, not having to mess with it will certainly save time/material. Probably been discussed also but is there a foam product/substitute out there that does not absorb water?? |

Posted By: TRBenj

Date Posted: October-21-2013 at 4:15pm

|

The "new" closed cell foam is supposed to be a lot better than the old stuff that was basically a sponge. But, I think it will still absorb water (albeit at a slower rate). I dont think an apples to apples replacement exists- but you can certainly go about putting the boat together differently and still meet the design intent of the original foam (strength and buoyancy). The most common no-foam build involves additional support members to replace the strength lost and help support the floor. Foam can be added under the gunnels instead, if youre worried about the boat going to the bottom. Joe's boat:

|

Posted By: Dreaming

Date Posted: October-21-2013 at 5:32pm

|

http://www.correctcraftfan.com/forum/forum_posts.asp?TID=21147&title=a-rough-1993-ski" rel="nofollow - KRoundy's 1993 thread Scroll in a couple of pages on this thread and you'll see the cross section of the cut hull. Kevin also took out a section of wet foam under the observers seat and replaced it through a hole saw cut. I think I would venture that a few hole saw cuts would be advantageous to the duration and success of the project. if your boat is really this wet, you need to find out where the water is coming from. Good luck with your project!  PS: KRoundy has not been around much lately, but I have his personal contact info. if you don't see him in the next couple of days, PM me and I'll give him a call. |

Posted By: sstewart

Date Posted: October-21-2013 at 11:12pm

| Thanks for the help, the 93 brochure is exactly what I needed about 2 weeks ago! So far I have cut about half of the floor out including the starboard stringer. I mistakenly had drilled a holesaw into it which revealed wet foam inside so I cut the top off of it as well to remove the foam. Not sure if I will leave the stringer alone on the port side, probably will kill me not to check for water so likely will cut into it. From the front of the engine to the bow has an original layer of glass, then a layer of blue hard foam, then quite a few layers of glass over this to finish up the floor (later will post cross section pics). I have cut out little sections to access the foam so far in this area (looks pretty ugly right now). I am gonna continue on the port side later this week. The very upsetting result of all this dirty work is that I only am up to 140lbs of wet foam so far which is a lot less than I had figured. Ironically, I'm hoping the remaining sections are full of water! Dreaming...I did read a lot from KRoundy which has been nice, and you are correct, every day I work on this boat I worry about where the heck the water is getting in to all these separate chambers..... For the most part the foam near the surface is dry and the bottom is usually wet but did it enter from the surface and gravity to the bottom or start from the bottom???? I want to dump it into a tub of dyed water after I am done to see where the water is getting in!! I do have a bunch of pics for reference and could make up a "how to" later when I have some time but I'm working against mother nature up here in Canada as it could snow any day now. Thankfully the weather has been very good lately. I also am contemplating taking the boat in to a fibreglass repair shop after I remove all the foam and clean it up so they can glass in a new floor. Anyone have an idea on materials costs to do this myself vs getting someone to do it for me. Also is glassing something I can do indoors (inside my garage) or do I need to be outdoors for ventilation. It's an attached garage and I don't want to stink up the whole house. Between work and this damn project my 3 little boys are wondering where the heck daddy is and why he never plays with us anymore! |

Posted By: TRBenj

Date Posted: October-22-2013 at 11:03am

| If you reassemble the boat with epoxy resin then you can definitely work on it inside- it does not outgas badly (unlike polyester and vinylester). I would highly recommend doing that- primarily so you can SLOW DOWN! I fear you are getting ahead of yourself, which could end up costing you more time and money. I suggest taking a bunch of pictures and posting them so we can see whats going on. We may be able to spot where the water is coming in- I know I have a few ideas on things you can check. |

Posted By: KRoundy

Date Posted: October-23-2013 at 12:10am

|

Scott, I got the PM and responded today. Email me! I have more photos that I can send if anybody wants to know what it looks like underneath the floor of a 1993. Ryan - that link brings back so many memories! Awesome. If you'd like to dig deep into my boat project this link has almost anything you need (including details on the floor repair and photos of a cut-up 1993 SN): http://kroundysboat.wordpress.com/" rel="nofollow - My boat blog I think that you are perhaps hitting the tunnel that goes near/under the driver's seat area. The stringers are quite a distance from the floor for the most part. If you are cutting with a cutting wheel or making sure you stay shallow with a saws-all you should be OK. But - as has been suggested - go slow! I also think it would be a good idea to drill a 1" hole and see if you find wet foam right away. Could you post a photo of your boat sitting (not moving) in water? I've been really busy with work and not on here as much. Sorry for the delay in response. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: Valcour

Date Posted: October-23-2013 at 2:34pm

|

With a post-93, all composite boat, the wet foam issue should be problem for weight, but not necessarily structure, i.e. no moisture-rotted stringers. In that case, how about tenting the boat with plastic in a heated facility, and running 1 or 2 dehumidifiers in the hull under the tent, routing the dehumidifier drain lines out under the tent? Maybe add a couple of fans in the boat to circulate the air. Might take a few weeks/months but should dry the boat out. We do this on racing sailboats at the dock during regattas, and everything is bone-dry overnight. Charlie |

Posted By: jimsport93

Date Posted: October-23-2013 at 5:47pm

KRoundy, don't know how I missed your rebuild blog. That is great information and helpful pictures. What a project....very nice  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=2798 - 93 Sport Nautique |

Posted By: KRoundy

Date Posted: October-24-2013 at 1:51am

Thanks! It has been quite a project. I'm excited to get out on the water next spring. :) ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: sstewart

Date Posted: October-24-2013 at 10:45am

Okay, hoping these pics uploaded correctly....anyway, Kevin, thankyou for getting back to me! Your blog has been very useful, especially the cross section of the bow from the nautique you cut up. I am going to spend a couple more days cutting out the rest of the floor to remove the remaining foam then think about blocking her up in the garage to prep it for glassing (with poly resin)when I have time so I can slow down :) I also cleaned out the hull with a garden hose yesterday and looked underneath to find water dripping out of the rudder so will likely replace the stuffing in that this winter and reseal my tracking fins. Otherwise, thanks for the help. Ohhh, the dehumidifier suggestion may have worked if I hadn't already completely destroyed my floor, knowing that may have worked kinda hurts a little :) Has anyone ever done this with success on a nautique??? Might be something to try down the road. |

Posted By: TRBenj

Date Posted: October-24-2013 at 11:08am

|

Beautiful Signature Edition! No, the dehumidifier is not a viable option. Theres just no way for the water to escape. Ive seen boats that were stored dry for years and theyre still soaking wet under the floor. Not polyester. EPOXY. I strongly recommend getting the engine pulled- it is going to save you a LOT of time and struggle when it comes time to rebuild that floor. If you are dead set on removing the foam from inside the stringers, I would only pull the top off them- that way you wont have to create a mold to pour foam back into the stringer cavity before reglassing it closed. It looks like youve cut up the floor in the front (sandwich construction) beyond saving, bummer. I would go back with a coosa floor throughout. That is the material shown above in Joe's boat, and is what we used on our http://www.correctcraftfan.com/forum/forum_posts.asp?TID=16014" rel="nofollow - Barefoot Nautique . |

Posted By: Gary S

Date Posted: October-24-2013 at 11:18am

|

+1 don't go thru all this work then cut corners on resin. Epoxy will adhere to all other resins too,poly will not. Being in Canada changes things but check out US Composites ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: sstewart

Date Posted: October-24-2013 at 12:13pm

|

my bad, meant epoxy resin..... |

Posted By: KRoundy

Date Posted: October-24-2013 at 2:45pm

|

Holy cow! Look at that composite boat. I wondered what mine would look like if I had cut out the entire floor. Now I know. How wet was it? Interestingly, the foam in the tree-killed boat was mostly dry. There was a little water on the bottom of the hull, but that was basically it. You have put in a lot of work there. +1 on removing the engine to make things easier on yourself. Once that big hunk of metal is in the way it is odd how small the boat suddenly feels. Please keep us up to date on your progress. Can you tell me why you want to remove the stringers? There is nothing wrong with them. I wonder what that blue foam piece under the driver's seat does? ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: TRBenj

Date Posted: October-24-2013 at 2:56pm

|

I think he wants to remove the potentially wet foam from inside the stringers... no way to do that without cutting them open. I'd extract it from the top if I was so inclined- no need to remove them entirely (I would probably leave them untouched!). What appears to be foam in the floor cross section is no doubt serving to build thickness and rigidity- that sandwich construction is how they built up enough strength for that part of the floor to span the open part of the bilge (25" wide). |

Posted By: Valcour

Date Posted: October-24-2013 at 3:35pm

|

Tim, Thanks for the clarification on the dehumidifier option. Wet foam is not something they I've had to contend with on race boats. It must slow draw in water (osmotic?) then trap it in a closed cell. Charlie |

Posted By: 8122pbrainard

Date Posted: October-24-2013 at 7:46pm

I happen to disagree. Put a wet sponge in a couple of "baggies" and see if it will ever dry out. Do you even use a moisture meter?? They work on foam too!!

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: sstewart

Date Posted: April-25-2014 at 6:40pm

|

Hello everyone, To update, I had great intentions of working all winter on the boat and it didn't happen. Currently I am 90% done removing the foam and floor. Generally just prepping to refoam and glass. With the help of another member via private message I have started a material list from US composites but would really appreciate the input of those experienced so I order the exact materials and amount. I'm from Canada so don't want to screw up the shipment. 80lb kit of 4lb density foam 2 gallon plus 1 gallon kit (total 3 gallons) medium epoxy kit 20 yards of 17oz biax 50"(includes floor and tops of 5ftx1ft stringers cut open) 3 rollers I am unsure which biax to use as there are a couple types and the original floor seems to have a top layer of strand and lower layer of woven mat cloth...I want to keep it as close or better than original. I also have a 2x4 area in front of observers seat I have to cover with either marine plywood or coosa. I could also call us composites and describe the job, anyone done that with success? appreciate the help! As suggested previously I will get some pics out, first one being when the floor prep is complete. |

Posted By: KRoundy

Date Posted: April-26-2014 at 5:19am

|

I wondered what had happened to your boat. Sounds like you are ready to dive back in. That is good. I'm sure somebody here can give you good information on what type of mat is best. I only did a small repair and didn't worry about it too much. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: sstewart

Date Posted: April-26-2014 at 2:53pm

|

Hey KRoundy!, I went through your blog again a couple nights ago, looking good! |

ScottStewart wrote:

ScottStewart wrote: