ProTec Ignition Swap

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Engine Repair

Forum Discription: Engine problems and solutions

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=34338

Printed Date: April-02-2025 at 2:03am

Topic: ProTec Ignition Swap

Posted By: JPASS

Subject: ProTec Ignition Swap

Date Posted: August-06-2014 at 10:31pm

|

So I just swapped out my original, leaking ProTec Ignition for a new D.U.I. set-up. I figured I would take some pics and attempt to do a write up to help out others who attempt this swap in the future. The entire job took between 4-5 hours. Here's a http://www.correctcraftfan.com/forum/forum_posts.asp?TID=33526&PN=1&title=protec-ignition-replacement-question" rel="nofollow - LINK to my original thread where many of my questions were answered with the help of the members from this forum. I went with http://www.summitracing.com/parts/dui-m35820rd/overview/" rel="nofollow - THIS DUI from Summit and http://www.summitracing.com/parts/acc-170036" rel="nofollow - THIS wire crimping tool. Make sure the main ignition breaker on the dash is off and the key is in the off position as well. Begin by disconnecting the TRIGGER PLUG from the ProTec dizzy. Next, loosen the dizzy lock down bolt located at the base of the dizzy.  Remove the bolt and lock down clamp and place them off to the side. Wiggle the dizzy while pulling up on it to remove the dizzy from the motor. Use a shop vac to clean up anything that may be down in the hole that may have fallen in during the dizzy removal. At the bottom of the hole you will see the hexagonal oil pump shaft. This sits in the bottom of the dizzy and must be fully engaged when installing the new dizzy.  Remove all of the stock plug wires from the spark plugs. Remove the EMS PLUG (wire harness) from the coil pack by loosening the bolt holding it to the coil pack.  Remove the three nuts on the underside of the plate that the ProTec coil pack sits on.  Remove the coil pack. The EMS PLUG is labeled for each wire going into it from the harness. Cut the wire at the back of the EMS connector going to P (12Vdc from key). Cut the wire at the back of the EMS connector going to D. Connect the wires from P and D together. This will provide 12V power to the dizzy.  Cut the wire at the back of the EMS connector going to E (Tach wire from dash). Cut the wire at the back of the EMS connector going to C. Connect the wires from E and C together. This will be the tach signal wire.  Cut the wire at the back of the EMS connector going to G (or M, both are Ground). Cut the wire at the back of the EMS connector going to B. Connect the wires from G and B together.  Install the new dizzy. Don't force it down into the hole if you feel resistance. If it doesn't engage the oil pump shaft properly (fully seated on the block), bump the ignition key while pressing down on the dizzy until the dizzy is firmly seated on the block. Cut the wire at the back of the Trigger Plug going to A Turn on the key and using a DMM set to measure Volts DC verify that it reads about 12Vdc Turn off the key Connect the wire from A to the DUI 12Vdc input wire.  Cut the wire at the back of the Trigger Plug going to B Using a DMM set to Ohms verify this wire goes to the back of the dash Tachometer (should be a low number close to 0.0 Ohms) or just verify it does not go to power or ground. Connect the wire from B to the DUI Tachometer output wire  If your dizzy requires a ground, follow the next step. My D.U.I. did not, so I removed the remaining wire on the Trigger Plug. Cut the wire at the back of the Trigger Plug going to C Using a DMM set to Ohms verify this wire is connected to Ground (should be close to 0.0 Ohms) Connect the wire from C to the DUI Ground wire Cut the last wire from the Trigger Plug and discard the plug and the last wire is not used The EMS connector can either be cut off or left alone. There is nothing going to the connector that would cause a problem. You will also have to disconnect the knock sensor plug wire that is attached to the EMS Plug.  ------------- '92 Correctcraft Ski Nautique |

Replies:

Posted By: JPASS

Date Posted: August-06-2014 at 11:03pm

|

Remove all of the spark plugs. It's preferred to go with new plugs, but if you keep the old ones, be sure to open the gap to 0.050 - 0.055 Remove the dizzy cap and find TDC on cylinder 1 (compression stroke). I did this by having a buddy crank the motor with a socket on the crank pulley while I held my thumb over the spark plug hole. Once I felt the pressure build, I knew I was on the compression stroke. I used a wooden dowel to stick down the hole to make sure I was at TDC. We hand cranked the motor until the dowel no longer moved up while contacting the piston head. Use a sharpie to mark the dizzy body where the rotor is now pointing. This is where the #1 spark plug wire must go on the dizzy cap. Reinstall the dizzy cap (should be notched so it only fits one way). Mark the #1 cylinder post on the dizzy cap. Refer to your owners manual for the proper cylinder numbering, firing order, and dizzy rotation. I used this diagram to run the wires (LH rotation 351W)  When getting ready to run your spark plug wires, be sure to separate them out by length. There should be 2 of each length. I ran each wire from the plug up to the dizzy and wedged the wire between the dizzy cap post to adjust the lengths to where I liked how they looked. Once you are certain the wires are in the correct order on the cap, you can begin to terminate the ends. I used this video to see how it's done as I've never done it before: Using the strippers on the crimper, strip back 1/2" from the wire end to expose the inner core  Place the terminal end into the crimper.  Fold the core back on the spark plug wire insulation and place that side into the curved (closed) end of the terminal. Crimp the wire.  Using a Q-Tip and some petroleum jelly, lube the boot and slide it over the terminal end. Install the terminated plug wire on it's appropriate post. Repeat for the rest of the plug wires. I would buy some plug wire organizers to keep things nice and tidy.    You're ready to try and start her up and check the timing. Timing should be 12 degrees at idle and about 34 degrees at 3K RPM. Your timing requirements may differ. Be sure you have a water source hooked as you don't want to run the motor or RWP dry.  Adjust the timing by rotating the dizzy until the correct timing is achieved. Once you are happy with the timing, tighten the dizzy hold down bolt and have a beer or 3 for all your hard work. ------------- '92 Correctcraft Ski Nautique |

Posted By: KRoundy

Date Posted: August-07-2014 at 2:05am

|

Great write-up, JP!!! As promised, this has been added to the FAQ. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: rosconole

Date Posted: August-12-2014 at 2:34am

|

dude your black spark arrestor cover is missing.. did it catch on fire?? 5.00 for timing tape...http://www.summitracing.com/parts/sum-163594?seid=srese1&gclid=Cj0KEQjw06GfBRCR9tDI4t6n5_MBEiQAFo6kuLzyOJkGoTRKxe6VIhr0nHaniyH_d8nu-PJ8vvS6ghYaAhyH8P8HAQ ------------- 1989 ski nautique ,1991 barefoot nautique, 1993 Mustang Cobra 1998 5.0 Magazine shootout invitee |

Posted By: KRoundy

Date Posted: May-25-2015 at 12:45pm

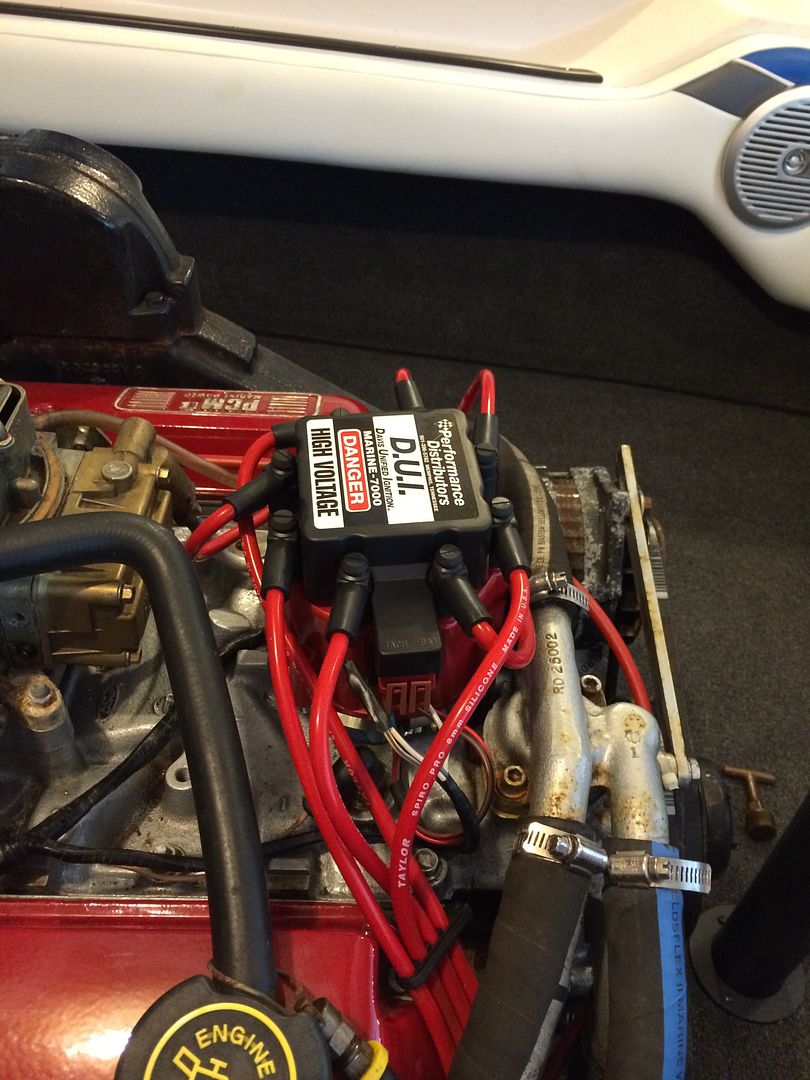

Shout out to JP this morning from me. JP - well done sir! Using only a print-out of this excellent write up, my engine bay now looks like this: I'll add in my two cents of additional thoughts. 1. Do everything as JP has written it up. 2. It likely makes sense but note the orientation of the DUI in both photos. If your DUI installation is at a drastically different angle there's a chance you are doing something wrong. 3. I trimmed that hose that goes from the valve cover to the inlet screen / fire arrester on top of the carb to provide clearance between that hose and the DUI. That seemed to work. 4. You need to buy new plug wires. I tried re-using the ones that were on my ProTec (they were relatively new), but the longest wires could not reach. Here is the wire set I purchased: http://www.summitracing.com/parts/tay-73251" rel="nofollow - Taylor Spiro-Pro 90-degree univeral wire set I followed JP's advice and got the same crimping tool and purchased a set of wire organizers too. Thank you JP! I can't wait to give this a go on the lake. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: Orlando76

Date Posted: May-25-2015 at 2:50pm

| Looks like I'll be doing this shortly as well as my idle seems a bit lope-y. I'm guessing the original Pro Boss cover doesn't fit with the DUI? Does any distributor fit under the cover? |

Posted By: KRoundy

Date Posted: May-25-2015 at 3:34pm

|

The original Pro Tec cover will not fit with a DUI installed. I do not know about other systems. JP mentioned trying to modify the cover to work. Any updates JP? I think if one were to trim it out the front edge of the cover it could work. I might tinker with that a bit today and report back. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: KRoundy

Date Posted: May-25-2015 at 3:36pm

|

Oh, and just one more comment - the idle was noticeably smoother with the DUI installed. The engine really seemed "eager" to run with the DUI. I'll also report back after my on-the-water test. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: Jonny Quest

Date Posted: May-25-2015 at 9:01pm

I got my DUI / HEI distributor and new carburetor to fit under my Pro-Boss cover:  ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: JPASS

Date Posted: May-25-2015 at 11:04pm

Kroundy: glad my write up helped. A big thanks to those who gave me the info I needed to be able to create that write up in the first place.

Mine fit, but the front lower edge of the cover made contact with my wires on the dizzy. I notched the cover in the front to give more clearance, but I wound up not using the cover. I'm also running a 4010 holley. Not sure if it's any shorter than the 4160. ------------- '92 Correctcraft Ski Nautique |

Posted By: Orlando76

Date Posted: June-21-2015 at 10:13pm

|

Thanks John. Unfortunately blue was all that was available. Doesn't look terrible. ------------- Please support The Cystic Fibrosis Foundation 1976 Ski Nautique 351 Escort 1993 Ski Nautique purple and black 351 HO PCM |

Posted By: malcolm2

Date Posted: October-23-2015 at 12:09pm

|

DUI and plug wires arrived... Excited about installing and test starting ASAP. I do have some questions for the folks that have done this.... My boat is a 92 with a Holley carb. Questions: 1. Coil Packs and wire connector are removed and disposed of, correct? 2. In the write up above, 1 wire on the EMS connector is not accounted for "F" (and the other ground, I plan to wire nut both ground wires, or follow them to the block and remove them.) But what about "F"? wire is labeled 30 and goes to the water temp switch and the OP switch. 3. are these switches only giving the EMS feedback, will they be useless once the EMS is gone? Again, I assume I should tape, wire nut or remove the #30 wire? Or if I am really bored, maybe pull the switches and block off the holes? 4. Not that it matters, I am curious tho. If wire 30 goes to 2 switches, how does the EMS know what each switch is (or was) doing?  Thanks for the great write up.... And for all who have replied. Clark |

Posted By: JPASS

Date Posted: October-23-2015 at 12:33pm

|

Let me try to answer your questions as I did this on our '92: 1) Do whatever you want with the coil packs and wires. I simply threw them away as the coil packs were leaking and I used an old spark plug wire to test out my newly acquired crimping skills. 2) F is no longer needed as once the ECM is removed, the sensor becomes useless. 3) Yes. I simply cut the wire back and capped it with some small heat shrink tubing. 4) No idea. Hope this helps. ------------- '92 Correctcraft Ski Nautique |

Posted By: desertskier

Date Posted: October-23-2015 at 12:59pm

|

I don't have a schematic for the EMS but I expect that the input at F is pulled up and when either switch detects a fault it is pulled to ground. The EMS can't tell which fault occurred, temp or oil pressure, but will go to limp mode for either. One of the ground connections is used when you connect G and B together. The ground at M is not used but if you want to connect them together it won't hurt. Also, I probably wouldn't use wire nuts for any of these connections. edit: My mistake. I forgot the DUI doesn't need the ground wire. So yes you can remove them or just leave them clipped off. |

Posted By: JPASS

Date Posted: October-23-2015 at 1:02pm

+1 Use heat shrink connectors for all of the connections being made. They're pretty cheap and readily available. ------------- '92 Correctcraft Ski Nautique |

Posted By: malcolm2

Date Posted: October-23-2015 at 1:08pm

|

GRACIAS. Thanks for the confirmation. |

Posted By: Air206

Date Posted: October-23-2015 at 1:40pm

|

Getting Ready to do this swap, just ordered from Performance Distributors. - got red (red is always fast) For the Barefoot, it's a Chevy 454......... Will Post Pics and variations. AWESOME write up! ------------- https://tinyurl.com/y6t5e3bu" rel="nofollow - 04 Air206 http://tinyurl.com/9urzgls" rel="nofollow - 91 Barefoot 78 SkiTiq |

Posted By: JoeinNY

Date Posted: October-23-2015 at 1:42pm

Good to hear, life is too short for ProTec issues ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: Air206

Date Posted: October-23-2015 at 2:05pm

Need to do it - feel too responsible for my friends slaving over a crappy ignition system while I scratch my head and get the eye wash station ready...........  ------------- https://tinyurl.com/y6t5e3bu" rel="nofollow - 04 Air206 http://tinyurl.com/9urzgls" rel="nofollow - 91 Barefoot 78 SkiTiq |

Posted By: desertskier

Date Posted: October-23-2015 at 2:25pm

|

While installing the DUI I suggest that you read the voltage at P on the connector or at the 12.5 Amp breaker point 26 on the diagram. Per the DUI website it needs to be above 10.5Vdc while the engine is cranking for the DUI to operate correctly. I didn't mention this to JPASS when he installed his because I believe he had already beefed up his dash wiring so I assumed he was OK. If the voltage is below 10.5 then you will either need to beef up the dash wiring ( easy to do. positive side only not the grounds) or install a relay that switches the 12Vdc at the engine to the DUI and is controlled by the key switch voltage (which is what CC should have done in the first place for the Protec). From DUI website: If all of your connections check out good, then check your battery voltage as you are cranking the engine. Since the DUI is a high performance ignition system it requires more voltage than a standard ignition system. If your battery voltage drops below 10.5 volts, this is not enough power to get the distributor to fire. This condition can be due to a weak or old battery or you are using a hot wire that has a resistor in line. Use a volt meter to test the hot wire while someone else cranks the engine over. If the voltage drops below 10.5, check your battery. To make sure it is not the hot wire, run a temporary jumper wire directly from the positive side of the battery to the distributor. If the distributor fires using the jumper wire, run a new hot wire from your switched 12 volt source to the distributor. |

Posted By: malcolm2

Date Posted: October-23-2015 at 9:40pm

|

OK, I am into this thing.... Took the pro-tec disty off and installed my new blue DUI. No one has mentioned that the water pipe and hose GET IN THE WAY. I have install the new disty at a very similar angle as pictured above. The only adjustment I am going to have is distance between 2 posts at the water pipe. Have not tried to put the hose back on yet... The disty cap had to be removed to get the unit to seat fully into the block. any thoughts? |

Posted By: JPASS

Date Posted: October-23-2015 at 9:57pm

|

Hmm. I never had any clearance issues with our '92. It was close, but there was plenty of room. Is the dizzy set so the rotor is pointing to cylinder 1 at TDC? Take a pic looking down on the dizzy so we can see whats going on. ------------- '92 Correctcraft Ski Nautique |

Posted By: malcolm2

Date Posted: October-23-2015 at 10:07pm

|

it may just end up being a tight squeeze. I am going to see if I can find a thinner walled hose tomorrow. I did not mess with TDC yet, but I dropped the unit into the engine in a very similar orientation to the above pictures in a previous post. Protec is off, wires are cut and a few have been totally removed..... Then I got thirsty and called it quits for tonight. more photos tomorrow in the day light. Clark |

Posted By: JPASS

Date Posted: October-23-2015 at 10:10pm

Here's some more shots of ours. It's close, but it fit.    ------------- '92 Correctcraft Ski Nautique |

Posted By: KENO

Date Posted: October-23-2015 at 10:27pm

|

Oddly enough, I can't remember what I had for supper tonight, but I do remember this issue coming up in the past. Do a google search and type in Correctcraftfan intake manifold you'll find a post started by Dan in CT on June 4 2014 with some info on how one guy remedied his problem with a spacer between the thermostat housing and the intake manifold. I'd include a link to it, but it would probably take me about 3 weeks to make that happen KenO |

Posted By: desertskier

Date Posted: October-23-2015 at 10:33pm

| http://www.correctcraftfan.com/forum/forum_posts.asp?TID=33765&title=intake-manifold" rel="nofollow - Manifold discussion |

Posted By: KENO

Date Posted: October-23-2015 at 10:44pm

|

Well look at that....... a link 6 minutes later Thanks |

Posted By: malcolm2

Date Posted: October-27-2015 at 2:41pm

|

http://www.correctcraftfan.com/forum/forum_posts.asp?TID=37573&title=voltage-for-my-protec-swap" rel="nofollow - http://www.correctcraftfan.com/forum/forum_posts.asp?TID=37573&title=voltage-for-my-protec-swap Link to further discussion on this subject. Specifically read the post I called GOTCHAS before you get too deep into this conversion. |

Posted By: desertskier

Date Posted: October-28-2015 at 9:03pm

|

Talking to another CC owner today he suggested that the oil and temp switch signals could still be used to activate the existing dash warning light/lights if you have them or whatever device you wanted to add. The limp mode function is gone so you have to turn the engine off yourself but an overtemp/low oil pressure warning led/horn or whatever you want to use might be nice. All you would need is a wire from the dash to the engine and connect it to F which goes to the switches. Then connect 12V to the other side of your device. After thinking about this a little more you could also wire something up that kills the ignition signal and turns off the engine. |

Posted By: michiel200

Date Posted: November-18-2015 at 5:36pm

|

I bought a used D.I.U. distributor and spark plug wires on Ebay. The seller sold his SN and switched the distributor and manifold for the old parts. Precaution on the ProTec on my '92 BFN with 5.8 HO. With the help of this very useful instruction I will do the swap this spring. The boat is in winter storage now. Many thanks for posting it! ------------- '92 BFN |

Posted By: nobrainsd

Date Posted: January-28-2016 at 2:04pm

|

I would like to thank JPASS and all of the others who have contributed to this thread. When my 94 Ski Nautique started to have intermittent issues I was sure it was the Protec system beginning to fail. It was great to find this thread with detailed descriptions and photographs. I had no trouble swapping out the carb and the ignition system. My boat has run reliably ever since! Perfect pass, a new 100 amp alternator, a closed cooling system, new manifolds and risers, a new carb (rebuilt), a DUI distributor, rewired harness, a mechanical fuel pump and the proper hard gas line... all thanks to CCF. I really appreciate the forum.

|

Posted By: Orlando76

Date Posted: January-28-2016 at 2:10pm

|

Is that really the correct timing in that picture? That's quite a few degrees different from the norm. ------------- Please support The Cystic Fibrosis Foundation 1976 Ski Nautique 351 Escort 1993 Ski Nautique purple and black 351 HO PCM |

Posted By: Hollywood

Date Posted: January-28-2016 at 2:14pm

| who's to say he has his plug wires on the same terminals as the "norm" |

Posted By: TRBenj

Date Posted: January-28-2016 at 2:27pm

| Distributor cap position, wire position... There is no such thing as "normal position". Order, yes- position, no. It all depends on the orientation of the distributor when it was installed. There is no right or wrong (other than cosmetics). |

Posted By: nobrainsd

Date Posted: January-28-2016 at 2:27pm

| DUI said that I could choose any one of the terminals to be #1. Just had to make sure that the progression from that point was correct. This orientation made the connections to my wiring harness conveniently placed. |

Posted By: JPASS

Date Posted: January-28-2016 at 2:37pm

|

Never really thought about it as everyone seemed to wind up with the dizzy in a similar position. Makes perfect sense to have it look different depending on the installation though. Glad the write up helped. ------------- '92 Correctcraft Ski Nautique |

Posted By: 8122pbrainard

Date Posted: January-28-2016 at 2:41pm

|

Todd, The norm can be anywhere in 360 degrees depending on where distributor gear is engaged on the cam. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KRoundy

Date Posted: February-05-2016 at 1:24pm

|

Hmmm... I guess this is true now that I think about it.. I guess it was just dumb luck that the first two installations were at the same orientation. ------------- Previous: 1993 Electric Blue/Charcoal Ski Nautique Current: 2016 Ski Nautique 200 Open Bow |

Posted By: backfoot100

Date Posted: February-05-2016 at 4:08pm

|

In virtually all of my engine books, the authors recommend to get the #1 terminal of the dizzy to point toward #1 cylinder. Probably for ease of remembering which terminal is truly #1. If you want to call that "norm" fine, but #1 terminal can point any direction you want it to. That's probably the reason that dizzy manufacturers have designed the caps to have the company name or logo facing in a particular direction when the dizzy is oriented in this manner. When it's different then the "norm" it looks odd. Hence, the DUI script on top of the cap facing a different direction then the "norm". I'm pretty sure most all of the DUI installs I've seen have the script going port/stbd. Ford or Chevy doesn't matter. The manufacturers take that into consideration. My MSD cap script is facing straight fore/aft in this pic. The cap and the terminal keeper is keyed so it can only go on one way and my dizzy is set so #1 is pointing toward #1 cylinder.  It's all about advertising and the money that advertising brings in. At least IMHO....LOL ------------- When people run down to the lake to see what's making that noise, you've succeeded. Eddie |

Posted By: 8122pbrainard

Date Posted: February-05-2016 at 5:07pm

Eddie, You're as OCD with your distributor caps as you are with the rest of the boat!  I love it! I love it!  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: nobrainsd

Date Posted: February-06-2016 at 2:12pm

|

Wow Backfoot100, that is a clean looking ride! Since everyone likes photos here is a shot of the 'T' coming off my manifold with the temp sensor on one end and a heater connection coming off the other. This is why my DUI is not squared up to the engine. Nice to be able to set it up any way I wanted to.

|

Posted By: michiel200

Date Posted: May-28-2016 at 10:54am

|

During the winter storage, I've swapped my ProTec for a DUI. I bought the distributor and cables in the US from a guy who had it installed on his S.N. but sold the boat with the old set. I followed the instructions in this post, but can't get the engine (PCM 5.8 HO) to start this week (the first week that the boat is in the water). Made the new connections, disconnected the EMS and Trigger plug I found out the TDC in cilinder 1, using my finger (feeling the compression) and a small wooden stick and a wrench turning the cranck. Marked the distributor where the rotor was pointing at and made this cil 1. Checked the firing order and connected all plug cables. After a couple of cranks, the voltage on the DUI dropped under 10,5 V, so I made a direct connection to the battery having 11,5 V on the cable connected to the DUI. When I remove a spark plug and crank, I see a clear spark. Gap is 0,05, plugs are new Motorcrafts from Skidim. Tried several distributor positions around the marked cil 1 position. Any thoughts from you guys? Many thanks in advance from Holland ------------- '92 BFN |

Posted By: malcolm2

Date Posted: May-28-2016 at 11:26am

|

do you have an inductive type timing light? Although you said you got spark on #1. You could quickly check all 8 with one of those. Sounds like you have installed it correctly and the DUI is getting the correct voltage. Maybe you have a fuel issue. Make sure you are getting fuel. Carb I assume? Even tho the disty is new, you should go thru std "no-start" troubleshooting procedures. Good Luck |

Posted By: michiel200

Date Posted: May-28-2016 at 11:45am

|

Hi Malcolm, I don't have an inductive timing light. My plan was to get the engine started and ask a local shop to set it on time. The spark on cil 1 was by just taking it off and crancking it. I already did some checks regarding fuel, since I replaced the fuel filter this winter. And the spark plugs looked quited dry, despite the cranking i did. So I passed the filter, connecting the tube direct from tank to pump. However, no result. I will look further in this direction. Thanks! ------------- '92 BFN |

Posted By: malcolm2

Date Posted: May-28-2016 at 11:55am

|

I did this swap and have a post called "Voltage for my pro-tec swap", search that. Or click on my name and look for my posts to find it..... Unless you have already looked at it. There are a few more details on DUI set up on my post. I was thinking about the timing light to check that you have juice from the DUI to each plug. If you clamp the inductive connector to the wires 1 at a time and power up the light, then turn the boat key and hold at start while you pull the timing light trigger, the light will flash (if you are getting juice), regardless of what cylinder wire it is on. Just point the timing light to the carpet. A quicker and less-shocking way to check that the DUI is working. You still don't know you get spark, but you eliminate the DUI as the prob. That is how I found out my coil packs were not working. Make sure the DUI cap is on tightly and properly. the hold down hooks are wonky. I can't remember what the DUI has for a rotor, but check inside once more. Careful on unfiltered fuel. Good way to block up your carb. |

Posted By: TRBenj

Date Posted: May-28-2016 at 12:13pm

| Verify timing order. The rotor rotates counter clockwise. |

Posted By: michiel200

Date Posted: May-29-2016 at 8:32am

|

This morning, I put the distributor more 'early' than I did before. And she started rightaway and ran smooth. For about a minute. The engine choked, obviously because of a lack of fuel. I started investing the fuel filter housing. Because this winter, I renewed the filter. But it didn't came with a new rubber ring. So I went to a local tractor shop, and they had a ring that fitted oke. Now it occurs that the ring was not oke, but too big (it expanded). It caused what we call over here 'false air', the housing was not closed tight so the pump was not able to get fuel into the carb. The engine ran on the fuel that was in the carb when I put the fuel hose straight on the pump, skipping the filter. So this week I get a new ring and have the timing set. And hopefully I can enjoy the new ignition. And a lesson learned not to work on fuel and ignition at the same time. This makes troubleshooting a lot more complex. Many thanks for your suggestions! ------------- '92 BFN |

Posted By: michiel200

Date Posted: June-07-2016 at 7:30am

|

Last weekend, I set the timing with a lamp and made a test drive. The result is amazing. It starts on the button and accelerates better than ever. Especially above 4000 rpm. It feels it gains an extra 40 hp at high rpm. I should have done this much earlier. JP, again many thanks for your instructions. This made the swap real easy. ------------- '92 BFN |

Posted By: Dreaming

Date Posted: June-16-2016 at 6:15pm

|

JPass - or one of the other guys that has done this swap, I am looking to get my order placed with summit, and would like to know which wire set you ended up with? the Taylor Spiro pro has lots of choices, so I want to make sure I get the correct item. I have gt-40 heads in my 94 - 90° boots or some other angle? are these correct? https://www.summitracing.com/parts/tay-70251/" rel="nofollow - Taylor Wires - Summit EDIT: LINK CHANGED TO 90° END KIT FOR FUTURE REFERENCE |

Posted By: Hollywood

Date Posted: June-16-2016 at 6:39pm

| 90s on both ends |

Posted By: Dreaming

Date Posted: June-16-2016 at 6:43pm

|

Perfect! Thank you ! |

Posted By: Dreaming

Date Posted: August-01-2016 at 2:16pm

|

Thank you JPASS - My DUI is installed and the boat runs! I have a 94 that came with the Protec Injection as well, This set of installation instructions works for TBI boats as well, as long as you are replacing the TBI with a carb. The TBI wiring harness is essentially separate with the exception of the interconnected tach wire and one other yellow wire. there are some extra sensors to input to the TBI module that will be abandoned in place. The wiring can all come out though. You will need to remove the 15A circuit breaker on the back of the engine ( leave the 60 and the 12.5) and you can reinstall the 2 remaining breakers on the bracket that the was originally mounted too. the FI module bracket is no longer needed and should be removed for accessibility. While you are working through the wiring harness, the original (Non TBI) wiring harness already includes wiring for the electric choke on the Holley Carb, all you need to do is un-tape the wires from the harness (they're covered up) and plug them in. Lesson learned: Nicely routed plug wires are great, but err on the side of making the wires too long... they looked fantastic until I timed the engine, and I wound up with a couple of wires that were tight... |

Posted By: desertskier

Date Posted: April-01-2019 at 12:58am

I recently replaced my Protec with a DUI. I used the same parts and did the installation basically the same as JPASS but decided to install a couple of relays as well. Here is the schematic and a link to the relays that I used https://www.summitracing.com/parts/pco-5593pt" rel="nofollow - Link to Summit Racing Relays P/N 5593PT The relays connect battery voltage directly from the 50amp breaker to the DUI rather than the existing method of routing the voltage through the dash and key switch. Relay #1 is normally open and will close when the key is turned to the on or start position applying voltage to the DUI. Relay #2 is normally closed and will open when the existing protec water temp switch detects an over temp condition. This will kill the engine if it starts to overheat. I was originally going to use the oil pressure switch as well but when starting the engine it takes a few cranks to get enough pressure to open the switch so the engine didn't start right away. I just disconnected the wire at the oil pressure switch and capped it off. I mounted a third relay as a spare. It's not connected to anything. |

Posted By: Jonny Quest

Date Posted: April-01-2019 at 1:51am

|

Nice, clean installation. I like the dedicated relay for the DUI dizzy. ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: KENO

Date Posted: April-01-2019 at 8:36am

This may seem rather silly of me, but why would you want to automatically turn off the engine at 200 degrees? It sounds like a good idea to protect the engine, but I'd say it's a "not so good idea" for the safety of you and anybody else in your boat. It takes away the ability of the driver to survey the situation and decide whether to keep running the engine till it self destructs if necessary. Take a situation where you're in the boat with serious medical issues like a heart attack for example. The driver is headed for the dock/launch ramp where medical assistance is waiting but your engine temp hits 200 degrees and it shuts down about 1/4 mile from life saving help. I guess you could say, "well I'm gonna die out here but don't worry, we saved the engine" or on the other hand " we cooked the engine but at least I'm still alive"  It was built with the limp feature instead of automatically turning off the engine on low oil pressure or high water temp for a reason. |

Posted By: Orlando76

Date Posted: April-01-2019 at 11:55am

|

Well Ken, while you’re clutching your chest dying just pop open the dog box and jump the relay! Did I miss where it shuts off at 200? That’s a lil low, I’d step it up to at least 230. ------------- Please support The Cystic Fibrosis Foundation 1976 Ski Nautique 351 Escort 1993 Ski Nautique purple and black 351 HO PCM |

Posted By: 8122pbrainard

Date Posted: April-01-2019 at 12:28pm

or cut ether wires at terminal 86. At what temperature does the temp switch close? 200? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: desertskier

Date Posted: April-01-2019 at 12:44pm

|

I did give that some thought. What I considered is that during 1600 hours of operation my boat has never overheated or gone into limp mode (except when the old wiring had too much IR drop - long time ago). Although the scenarios you mention and others are possible I believe the risk is extremely low. It would be nice to have the limp mode feature still but without it I would rather save the motor. My boat doesn't have the dash alarm/lights but for those that do it would be easy to replace relay #2 with a timer relay. You could set it to a few minutes so your alarm went off before it killed the engine. I was also curious what the DUI does when the input voltage drops but I didn't experiment with that yet. It may start running crappy at some point which would give the driver a heads up. So all you would need is a voltage divider on the output of relay #2 that connects to the DUI wire. According to skidim the switch closes at 210. For some reason I thought I had read somewhere it was higher than that. If it turns out to be a problem it's easy to disconnect unless of course I had a heart attack and crashed then it would be harder. |

Posted By: desertskier

Date Posted: April-01-2019 at 12:57pm

Installing just the first relay would be really easy since you have already done everything else. Just connect 87 to the dizzy without the second relay. I know how much you like projects! But if you want to protect that new roller motor I would install #2 also. |

Posted By: KENO

Date Posted: April-01-2019 at 2:37pm

Good to know you gave it some thought  I've seen the switch listed in PCM literature as both 210 degrees and 200 degrees depending on where you look. It's the same part number for a ProTec engine and a GT40 engine. If I wanted some kind of protection/warning from the oil pressure and/or water temperature switches, I'd probably wire both to relays that fed a loud, obnoxious horn to let the driver know there's a problem and he/she could turn the engine off or keep running it depending on the situation. That way O-76 or whoever's driving wouldn't have to find the right relay and yank it and Pete wouldn't have to pull out his wire cutters and snip the right wire in the middle of a "not so good" situation. I suppose in the end, it's whatever you're comfortable with |

Posted By: wkebrdr

Date Posted: April-09-2024 at 11:56am

|

I searched around, but what spark plugs are you using since going to the DUI? ------------- Bill 92 Ski |

Posted By: malcolm2

Date Posted: April-09-2024 at 12:23pm

|

I will have to check. I don't remember off-hand. I will get back here and reply with that. It has been quite a while, and I will say that this change was fan-dam-tastic. No more hiccups, super quick starts. ZERO ISSUES.

|

Posted By: Jonny Quest

Date Posted: April-09-2024 at 1:18pm

|

Autolite 764 or 104 plugs. 0.055 gap with the DUI. JQ

------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: KENO

Date Posted: April-09-2024 at 6:08pm

Since this is your first post, nobody knows whether your engine has the standard heads or gt40 heads. So..........the bestest, most correctest answer is to use the same plugs that are in it now because there were different plugs depending on the heads used

|

Posted By: 1993R

Date Posted: June-29-2024 at 7:36pm

|

I just did this conversion on my 92 ski Same boat as JPAss Everything installed easy and my distributor is positioned just like the photos TDC has been checked twice. Wires installed properly. Only issue is motor and starter are turning but no fire to plug wires Checked power to the HEI and it’s moves between 11 and 12 volts when cranking Checked my grounds seem okay Haven’t run new the power and ground wires to dash yet DEI said it sounded like the unit needed to be grounded and offered a suggestion on how to test it It didn’t change anything Any suggestions ? |

Posted By: KENO

Date Posted: June-30-2024 at 1:36pm

|

Where are you checking power to the distributor? At the (+) terminal on the cap Is the tach terminal hooked to the boat's gray tach wire? Nothing else hooked to the tach terminal Silly question, but is the 3 wire plug from the distributor plugged into the cap firmly? All 4 connections on the ignition module under the cap connected?

|

Posted By: rosconole

Date Posted: June-30-2024 at 4:01pm

|

Just hold the wires together put your foot in a bucket of water and crank it. Let me know if you feel anything. ------------- 1989 ski nautique ,1991 barefoot nautique, 1993 Mustang Cobra 1998 5.0 Magazine shootout invitee |

Posted By: KENO

Date Posted: July-03-2024 at 11:23am

You got this thing making noises like a running engine yet?

|

Posted By: 1993R

Date Posted: July-03-2024 at 1:44pm

|

Keno I will be jumping in it tonight

Got tied up at work but have next 5 days off You may have solved it via the tach wire I don’t have it going directly to the HEI Will route it properly and hopefully she fires up It’s been pretty hot in FL so early morning late nights are only times to work on stuff and feel comfortable Would like to get back to skiing again Will keep you posted Thanks |

Posted By: KENO

Date Posted: July-03-2024 at 7:22pm

|

Hope you get going in time for the long weekend  The Red wire in the picture is the only one that needs to be hooked up. The connection next to it is for the tach and if it's grounded, the coil won't spark. It's normally hooked to nothing at all or to the tach wire that runs up to the dash. https://ibb.co/PjLxVwP" rel="nofollow">

|

Posted By: 1993R

Date Posted: January-06-2025 at 2:34pm

|

Update Sorry for the long delay My boat is up and running strong and starts like it’s brand new again I did some extra work to get there I did replace the starter solenoid and both push button fuses I rewired everything in 10 ga including the tack wire and the power wire to the HEI Removed all non essential wires from harnes Refinished the old protect mount in black crinkle finish and loomed all the wires Install looks clean and factory Boat fired right up Only two questions 1) the electrical connections had a black silicon applied at factory to help water proof Anybody know if it’s a specific brand and type. I would like to reapply . 2) The timing is currently set at 10 BTC and 800 rpm. I want to adjust it . From what I’m reading it should be 12 BTC at 600 rpm at idle correct ? I plan on retiming the boat but will be sending the carb out for a complete refresh and want everything to be spot on Thanks |

Posted By: KENO

Date Posted: January-07-2025 at 8:48am

|

I'd check the total advance at about 3500 RPM before doing anything, so you know what you have. DUI likes to say that there's 24 degrees of advance at 3000 RPM the way it's shipped to you. Add that 24 to 10 degrees of initial and you get 34. It seems like numerous people around here get anywhere from 20 to 24 degrees added to their initial when they check, with a lot in the 22ish area. 34 plus or minus 2 would be a good total number to have depending on what octane gas you're using. So setting it for whatever initial gives 34 total would be a good start. You might be there now or have to advance it a little 600 ish RPM in gear sounds good for idle RPM Not knowing what connections you want to cover in black goop, I guess I don't really see the need I'd wait till the carburetor comes back before doing the timing and idle adjustments unless you just want to practice doing it

|

Posted By: rosconole

Date Posted: January-07-2025 at 8:53am

|

40 degrees of timing ??? are you trying to sell an engine as well?? A GT 40 perhaps . ------------- 1989 ski nautique ,1991 barefoot nautique, 1993 Mustang Cobra 1998 5.0 Magazine shootout invitee |

Posted By: KENO

Date Posted: January-07-2025 at 9:17am

Umm, Roscoe, maybe you need to clean your glasses or go brush up on your math skills or something.

|

KRoundy wrote:

KRoundy wrote: