No spark / running out of ideas

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Engine Repair

Forum Discription: Engine problems and solutions

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=49596

Printed Date: November-21-2024 at 7:49pm

Topic: No spark / running out of ideas

Posted By: Jimscorpsewhale

Subject: No spark / running out of ideas

Date Posted: February-03-2021 at 7:46pm

|

I have a 1985 SN 2001 RH rotation with a 351. I pulled off the old heads and put on some gt40 heads from 5.0 as well as an edelbrock performer intake. I did new plugs and wires at the same time. After I put everything back together I don't have a spark... Initially it looked like the distributor cap was bad. The spring loaded connection between the cap and the rotor was tired and didn't seem to be making a connection. I replaced the cap/coil and got a new battery with more cranking amps ( i think 900) at the same time. Still no spark. I tested the timing light on a car at this point as well and it does work.... I then replaced the distributor with a davis unified ignition. The cables from the battery to the solenoid were pretty corroded so I replaced those. There was some dip in the voltage to the coil with cranking so I got a second battery and connected the hot wire to coil to it to make sure I was getting 12v to the coil. Still nothing. The DUI people said that the distributor would need to be spinning ~ 300 rpm to make a spark. The starter was not doing that so I replaced it (solenoid to) and while the cranking speed is much better Im still not getting any spark. I cleaned the ground site on the block really well. I not sure if maybe raising the compression is making it harder on the starter and I dont have enough cranking speed. I may add another battery I have in the garage to the mix. I did the test that DUI prescribed on the coil/distributor and it seems to check out. I emailed them as well. I'm stumped.

|

Replies:

Posted By: JoeinNY

Date Posted: February-03-2021 at 8:19pm

|

Have you seen the distributor actually turn when you are cranking it over? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: Jimscorpsewhale

Date Posted: February-03-2021 at 8:38pm

| Yes the rotor turns when I crank it |

Posted By: MourningWood

Date Posted: February-03-2021 at 11:13pm

|

Was the motor running before doing the modifications? ------------- 1964 Dunphy X-55 "One 'N Dun" 'I measured twice, cut three times, and it's still too short!" |

Posted By: slmskrs

Date Posted: February-04-2021 at 1:04am

|

Okay, ignore (almost) everything I said below the dotted line since I thought you had conventional coil and points. After writing that up, I when back and saw that you replaced the distributor with a David Unified Ignition (distributor). I thought you had gotten a new coil, not an electronic distributor, so had to look it up. That said, I honestly don't buy the '300 RPM or it won't spark line). A standard coil and points will spark (if appropriate voltage) whether it is 5,000 RPM or 1 RPM. The problem with this all-in-one unit is it is hard to determine where the problem lies, as well as trigger a spark. You said you have +12v voltage to the unit. I'm assuming it has the snot grounded out of it so you don't need a separate ground (negative) connection. However, in this picture https://www.jegs.com/i/DUI/314/M35820BK/10002/-1 I see red and black wires, so it could be possible that it needs a separate ground along with 12v power. Make sure you have a good ground; maybe the electronic module is internally isolated and it needs its own ground separate from the distributor body, and it needs to be a good ground. What's the test that DUI had you do? I'm curious. That info will help us understand what is going on, and how that test confirms operation. There should be a way to confirm that it will generate a spark. And even if you installed the distributor incorrectly (not at TDC), the most that would do is to cause a spark at the incorrect time in one of the strokes. But there should still be a spark. So that isn't it. At this point, I suspect a wiring issue (ground), or an issue with the unit. The problem is you don't have a separate coil so you can test that high tension line or the coil itself. If it is powered correctly, then either it is not sensing the rotating shaft (pick up), or it is flat out DOA. Interesting, my '97 with PCM GT40 MPI and electronic ignition still uses a conventional distributor cap and rotor; the 'coil' is part of the ignition module, which is near the throttle body, but it has a high tension line that goes to the center of the distributor just like a convention points distributor (except instead of points it has a pick up that sends the signal to fire a spark to the module). Let us know. -------------------------------- IF YOU HAVE STANDARD COIL AND POINTS: I'm assuming this is standard ignition, not electronic ignition. Since you have 12v to the coil, I'd look at the backside (negative) wiring from the coil. The negative side goes to ground via the points. The coil charges up when powered (points close), and when power is disconnected (points open), the coil releases the spark through the high tension wire.I'd do the following: 1. Check the points gap? Are you sure they are opening and closing by the distributor shaft lobes as it turns? I've had them work lose before on a car and stop opening. 2. With the ignition on (12v to the coil), you should be able to manually open and close the points with a screwdriver. The points will probably spark slightly, and if you run the coil high tension output to near a ground, you should get a good strong spark. 3. If you still are not getting a spark and you still have 12v to the coil, jump the negative side of the coil directly to ground). You should be able to short that negative wire fro the coil directly to ground (which imitates points closing, thereby powering/charging up the coil). When you un-short it from ground (which is the same as the points opening), you should get a spark out of the high tension line. If you don't, then your coil is suspect (note: Don't leave the coil connected to ground for long periods; it may overheat). 4. If you get spark when shorting and un-shorting the coil negative side to ground but don't when you move the points, then you have a wiring problem between the coil and the points. 5. If you see a lot of points sparking when opening/closing them by hand and you are getting a weak or no spark from the high tension wire, it could be the condenser is bad. That rarely happened back in the day where all cars had points, condenser, and coil (at least in my case), but you will not get a good spark if the condenser is bad (or it could even be shorting out). So if you did all of the above with no spark, I'd probably change it. If you do have electronic ignition, the electronic module has some sort of sensor in the distributor that signals when it needs to disconnect the coil-to-ground connection, releasing the spark. So if you can get spark by jumping the negative side of coil repeatedly to ground and get spark, but you don't with the electronic module, then the module is suspect. Let us know what you find out. ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: slmskrs

Date Posted: February-04-2021 at 1:15am

|

BTW, on my '96 (with the same GT40), I replaced my original heads with GT40P heads (originals developed hairline cracks in the water jacket and started leaking externally). They raised the compression (giving me 200 more RPM, 1.5mph faster at WOT, and better economy). But you couldn't tell the difference when turning it over/starting it (ie: starter seemed to turn at the same or near same speed; regardless, enough to start every time). Granted, going from standard heads to GT40 heads may be more of a compression change than going from stock GT40 to GT40P heads, but engines can crank pretty slowly and still start as long as they get spark at the right time (just takes one cylinder to fire which increases rotation speed and the rest fall in place). The biggest problem I've seen with slow cranking starters has generally been because of low battery power/low voltage. That will cause no spark, but you certainly don't have the problem of low voltage to the module/coil during cranking. ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: slmskrs

Date Posted: February-04-2021 at 1:29am

|

Okay, one more thing. Conventional ignition uses a ballast resister that lowers the voltage to the coil when the engine is running to keep the coil temp down. I'm assuming that your instructions for the DUI said to bypass any ballast resistor since the module should be modulating any voltage change needed in the internal coil to manage temperature. When you 'start', a full 12v goes to a conventional coil (needed especially since overall voltage drops while the starter is cranking), and it drops when the key is released to the 'run' position when there is no more starter load, and the alternator kicks in and increases the voltage. Electronic ignition should not need it. So just checking to make sure it isn't needed and you bypassed it. It would not make a difference in your situation when you are trying to start the engine since you should be getting the full 12v, but it could affect operation once started if the voltage is now low to the module. ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 6:57am

| It ran before then”improvements”. The ballast resistor was already bypassed prior to the DUI. I can take some pictures and describe the tests later today. |

Posted By: 8122pbrainard

Date Posted: February-04-2021 at 7:25am

|

James, Get the VOM back out and check the resistance between a good ground on the block to the DUI. This should tell you if the DUI has a good ground? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 7:56am

| I did. I think I had 5ohms between the ground and block. I also took a jumper cable from the shaft of the distributor to the negative pole of the battery. |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 7:57am

| 5 ohms would be pretty reasonable right? |

Posted By: JoeinNY

Date Posted: February-04-2021 at 8:04am

No - a value of .5 would still be to high ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1477 - 1983 Ski Nautique 2001 1967 Mustang 302 "Decoy" http://www.youtube.com/watch?v=cO5MkcBXBBs - Holeshot Video |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 8:15am

| Ok I will check it again and report back. I would have thought adding the jumper cable as a ground would have bypassed the problem. Or not? |

Posted By: 8122pbrainard

Date Posted: February-04-2021 at 8:16am

|

Jame, A rough calculation for voltage drop with a 5 Ohm resistanve is almost 4 volts. Check the actual volts the DUI is seeing when you are cranking the engine. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: slmskrs

Date Posted: February-04-2021 at 11:46am

|

It sounded like he's getting good voltage on the plus side of the input to the DUI, but to your point, with a 5ohm ground resistance, 12v isn't getting to ground. Jim, I take it there is only one wire connection to the DUI, the +12v supply line, and not a separate ground connection (ground is through the distributor). Let us know when you get a chance on the tests DUI had you do to confirm operation. ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 12:40pm

| Yes there is a 12v wire in. The coil has a black wire that grounds it to the body of the distributor. What would y’all suggest for adding a ground? Clamp a wire to the distributor shaft and ground it to the battery? |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 12:45pm

|

https://performancedistributors.com/wp-content/uploads/2019/11/GM%20Street%20DUI%20Instructions.pdf Im not the most computer savvy. My apologies. The above link is the trouble shooting thing from dui. I have done everything other than the module test at the end. The trouble shooting part is at the end |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 3:24pm

| When i check the resistance between the ground wire on the coil to were the battery cable is grounded on the block I get 1.8 ohms. The ground should be ok? |

Posted By: slmskrs

Date Posted: February-04-2021 at 5:57pm

|

Did you follow all seven troubleshooting tests in their .pdf? ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: SNobsessed

Date Posted: February-04-2021 at 6:02pm

|

If nothing else, you can pull the dizzy, hook it up to a battery & a spark plug (with grounds of course), then spin it by hand or drill. If no spark, send it back. You can do same thing with original dizzy to see if that one works too. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: slmskrs

Date Posted: February-04-2021 at 6:05pm

|

Ah, sorry, I see you did everything but testing the module. Frankly, I'm surprised that they want you to disassemble it and take it to a shop that has the ability to test the module since it's brand new. I guess you'd need to find someone that sells them to see if they can test it. I have no idea what test equipment is required, or if most auto parts stores would have them. Also, the coil and magnetic pick up tests only test static resistance. They don't have you do a manual energize test on the coil, nor do they have you do anything to confirm that the magnetic pick up actually sends the signal. I know this is a lame question, but is the pick up wheel/spokes there and lined up to where the pick up sensor is? ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: Jimscorpsewhale

Date Posted: February-04-2021 at 8:39pm

|

I talked with dui today and they are going to send me a new module. Pick up wheel and spokes? Not sure exactly which part we are talking about. |

Posted By: slmskrs

Date Posted: February-04-2021 at 11:21pm

|

There is generally a sort of wheel / disk / spokey'thing that rotates on the distributor shaft that the magnetic pick up is aimed at. That's what gives the module the 'pulse' to fire the coil. If there's nothing spinning near the magnetic sensor, it won't fire. ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: slmskrs

Date Posted: February-04-2021 at 11:22pm

|

It has eight spokes, knobs, bumps or some such thing for each cylinder. ------------- Gordon '97 Ski Nautique, GT40 |

Posted By: Nautiquehunter

Date Posted: February-05-2021 at 7:09am

| Did you hook up anything to the tach side of the distributor cap next to the 12 volt feed? If you did try unplugging it. |

Posted By: Jimscorpsewhale

Date Posted: February-05-2021 at 12:05pm

|

Slskrs- there is a connection from the coil down to the rotor that seems fine. It’s spring loaded. The rotor has a small piece of metal at the end that contacts the connection to the plug wire. That all seems good. I did try it with the tach wire unplugged but it had no effect. I plan to change the module and then if that doesn’t help pull it out and do the above suggested drill based test.... |

Posted By: SNobsessed

Date Posted: February-05-2021 at 12:12pm

|

I'm gonna dis my own suggestion & say it ain't worth the time, as long as you are sure rotor is turning when engine cranks. If you are getting 12V to input of dizzy & have a good ground, then it is either trigger module or coil. I assume you have good connection to spark plug wires. Have you tried to pull plugs & watch for spark from them? You replaced starter - are you sure it is turning the right direction? I worked in a heavy equipment assy factory & we had brand new electronics modules, that had passed testing at supplier, fail every day. Amazing, isn't it. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: KENO

Date Posted: February-05-2021 at 7:48pm

Here's a picture of how to do what SNobsessed described for your DUI distributor. (You'll have to rotate the picture or your head 90 degrees) It's from the electrical section of "The Backyard Hack's Handbook" It's really pretty easy to do and it'll tell you if the distributor makes spark. Clamp the distributor in a vise Clamp a pair of vise grips to the vise Take a spark plug wire and a spark plug and ground the plug by stuffing it into the vise grips like shown, and hook the other end to any terminal on the distributor Take a 12 volt battery and 2 test leads and hook the Negative lead to the vise grips. This now has your distributor grounded to the battery thru the vise and the vise grips and the plug is grounded too so it'll spark when you spin the distributor in a little bit. Now take the other test lead and hook it from the battery positive to the 12 volt feed to the distributor (the red wire in my picture) The Green tach lead in the picture doesn't need to be hooked to anything. The only thing left to do now is spin the distributor shaft by hand and if it works you'll hear a distinct little "pop" 8 times per revolution and since you have one plug hooked up, you'll see the plug spark once per revolution or every 8th pop. Now you'll know if it works If it does, your problem is elsewhere. Don't forget to unhook the power wire after you're done spinning it. If it doesn't work, at least you have a new module on the way and since you said you've done all the other tests, that just leaves the module to replace. If you put in a new module, you'll need some thermal paste/heat transfer paste to spread on the bottom of the new module when you install it, or the module won't last to terribly long. BTW The distributor in the photo is for a Chevy so the housing looks a little different, but that doesn't matter. And you'll see that it definitely doesn't take 300 rpm for it to spark  This works with the HEI with the coil in the cap, if you wanted to test your old distributor, you'd need to wire up a coil too in order to test it. So..............That's how an accomplished hack would do it. It took a lot less time to do the test than it did to write this post

|

Posted By: MrMcD

Date Posted: February-05-2021 at 10:18pm

|

Nice write up Ken. ------------- |

Posted By: Jonny Quest

Date Posted: February-05-2021 at 10:59pm

|

KENO: That is some quality hackery, no doubt. Yankee ingenuity meets redneck. Sure y'all not from the South? ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: Morfoot

Date Posted: February-06-2021 at 7:47am

Easy now there fella..... We may be dumb down here in the south but we ain't stupid!  ------------- "Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman" |

Posted By: Jonny Quest

Date Posted: February-06-2021 at 8:55am

|

Foot: I’m from Texas and fluent in redneck...hell, I AM one. JW ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: Duane in Indy

Date Posted: February-06-2021 at 9:24am

As always, Ken came to the rescue. Nice job Ken. Now go put the distributor back in the wife's ride before she sees it is missing. ------------- Keep it as original as YOU want it 1978 Mustang (modified) |

Posted By: JDD33

Date Posted: February-06-2021 at 11:05am

|

One item you might want to check is your ignition switch. Had a situation with a DUI that I installed in a buddy’s 74 SN. When he came over with the boat he forgot his key, no problem I had a spare ignition switch we installed and away we went. Installed the unit, new wires, timed it water tested it and it ran awesome. Got back to the house, unloaded the tools reconnected his ignition and away he went. Next day he went to the lake with his family and the boat ran poorly and wouldn’t start then had to get towed. Long story short.... after testing the next day the dizzy was was getting 12v in the run position, however was getting 0v in the crank and run position. Put my ignition switch back in and it’s been running like a champ for 2 years. Just a thought... ------------- Old school goin back to school! |

Posted By: Jimscorpsewhale

Date Posted: February-08-2021 at 6:40pm

| Keno thanks for the setup pic. I got the module today and will try to get installed in the next couple of days. If it doesn’t spark I’ll try out your setup! |

Posted By: Jimscorpsewhale

Date Posted: February-09-2021 at 7:36pm

|

So I pulled the distributor out today and did the test as described by KENO. I had a spark. Certainly as Keno said I didn’t need any significant rpm to do it. Couple of things. When I put the timing light on the wire when I spin the distributor I don’t get a light even when I am seeing a spark at the plug. I went back and put it on one of the cars and it worked fine... The wires are msd 8.5 mm. I had to change them when I switched to the dui. That being said I didn’t have a spark with the old set of wires and stock distributor either... I’m not sure I trust the gun.... maybe I had a spark then... I may do kenos test with the old distributor as well. I’m going to put a old plug in the number one hole and repeat the test with distributor in place and the actual plug I’m using grounded and visible to see if I have a spark with the distributor in place. Any idea why the gun doing that? Other thoughts or suggestions are highly appreciated! |

Posted By: Jonny Quest

Date Posted: February-09-2021 at 9:14pm

|

Bad timing light? ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: Jimscorpsewhale

Date Posted: February-09-2021 at 9:42pm

| Just not sure why it works on the car but not the boat.... |

Posted By: KENO

Date Posted: February-10-2021 at 7:46pm

What style of timing light were you using? I did the test the other day with an old light that just flashes and it flashed when the plug sparked. Then I did it with one of them new fangled digital readout advance style lights that reads RPM too...........and it wouldn't flash while spinning by hand although there was spark at the plug. Worked fine on a car, so same results you saw. I have a little backyard hack distributor machine and if the distributor was at maybe 50 rpm, then the light started flashing so it looks like something in the circuitry keeps the light in the digital timing light from flashing till some certain very low speed I'd buy a little in line spark checker that goes between the plug and the wire to make it easier to see if the plug is getting spark and crank that thing over and see if there's spark. Depending on that result, I may have a suggestion or 2 or some more questions also

|

Posted By: Jimscorpsewhale

Date Posted: February-10-2021 at 8:17pm

| Yeah I used one of the digital readout ones w/rpm. I think my father in law has and old style light he can bring next week. I’ll get an inline checker and report back. I was also going to put the plug wire from the boat on one of the cars and see if the gun worked there. I put a speed wrench on the distributor while we had it on the bench top setup but I’m not sure if I hit 50 rpm... |

Posted By: KENO

Date Posted: February-10-2021 at 11:26pm

|

If you want to hit some high speeds, sacrifice a 5/16 allen wrench and cut it so you have a straight piece that can go in the drill. Stick that in the end of the distributor shaft and let her rip. It doesn't really matter, but run the drill in the normal forward direction and that will spin the distributor rotor in the counterclockwise direction that it turns in the engine, if you're looking down at the top of the distributor If you have the drill spinning the distributor at 500 rpm for example, that would be like the engine running at 1000 rpm since the distributor turns at half the crankshaft speed. Then you should see some flashing from the light as you speed things up  I think it's safe to say the distributor works and if the only way you checked for spark was with the timing light, you should just install it, make sure the timing is roughly set close enough for it to start (#1 at about 5 to 10 degrees before TDC on compression stroke, right firing order(18456273) going CCW around the cap from the correct #1 position and crank it over with the in line spark teste( or a plug) to see if you have a spark, hopefully it starts and you then can use the light to set the timing where you want it like about 10 to 12 degrees BTDC as a good starting point and seeing if you get 32 to 34 degrees total at 3000 rpm

|

Posted By: Jimscorpsewhale

Date Posted: February-11-2021 at 7:11am

| Just want to make sure I have right in my head. The rotor spins counter clockwise to 5-10 degrees btc will have the rotor cross the #1 post on the cap 5-10 degrees before the motor is a tdc. I have it lined up a tdc now so rotate the cap about 10 degrees clockwise. |

Posted By: KENO

Date Posted: February-11-2021 at 8:28am

|

If you want to get 10 degrees of crankshaft advance (which is what you're wanting to do) then rotate the distributor 5 degrees clockwise. That'll give you 10 at the crankshaft, it all has to do with the distributor on a 4 stroke engine rotating at 1/2 of the crankshaft speed.

|

Posted By: Jimscorpsewhale

Date Posted: February-11-2021 at 2:41pm

| I didn’t think about the 1/2 rotation speed. Thanks! |

Posted By: tryathlete

Date Posted: February-11-2021 at 3:25pm

Tried to troubleshoot Quinner’s boat with a bad light. How frustrating. |

Posted By: Gary S

Date Posted: February-11-2021 at 4:45pm

But you got it in the end though, right Pete?  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: Jimscorpsewhale

Date Posted: February-14-2021 at 2:32pm

|

So I got the inline spark tester and it lights. I guess I have probably had a spark the whole time but have been chasing the wrong thing due to the timing light. I lined the number one up with the rotor at tdc. Eyeball rolled the cap about 5 degrees counter clockwise. I don’t get anything that sounds like it’s trying to fire. I’ll get a timing light that you plugs in line instead of the inductive type. I smell gas and when I first hooked the fuel line back to the carb I had a bit of a leak so I know it’s pumping. Any thoughts? |

Posted By: tryathlete

Date Posted: February-14-2021 at 2:42pm

It has been and always will be about that toolbox. |

Posted By: Gary S

Date Posted: February-14-2021 at 3:02pm

|

My thoughts are - number 1 cylinder at TDC when dropping distributor in ? When looking at the engine from the front, number 1 cylinder is the front one on the left. Where ever the rotor points to after the distributor is seated is where your number 1 wire goes to, then follow your firing order around the cap . The other question is did you by any chance change starters since it’s last run? ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: Jonny Quest

Date Posted: February-14-2021 at 3:58pm

|

I haven’t gone back to read every post, but perhaps the distributor is 180° out. You may want to verify that you are at top dead center (TDC) on cylinder number one on the compression stroke and then reinstall your distributor. JQ ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: Jimscorpsewhale

Date Posted: February-14-2021 at 3:59pm

| I believe I had it at tdc. I manually cranked it by hand with my finger in the spark plug hole. I could hear it building compression as the air leaked and it placed it at the tdc mark on the balancer. I did change starters. The distributor was in place when I made that change. |

Posted By: Jonny Quest

Date Posted: February-14-2021 at 4:06pm

|

It’s possible that your timing marks or pointer on the harmonic balancer is off. Make sure that you are on compression stroke on number one cylinder. You can check compression stroke the same way that you did before by holding your thumb over the spark plug hole and then rotating the the engine slowly clockwise. Once you know that the piston is coming up on compression stroke, you can insert a thin dowel that is 6-8” long into the spark plug hole and then slowly rotating the engine. Make sure that the dowel is in contact with the top of the piston, as you rotate the engine slowly. When the dowel stops moving up then that means you have reached top dead center. You can then verify that your timing mark on the harmonic balancer and the indicator are also showing top dead center. I’ve seen people chase timing only to discover that the timing marks are off. Edit: turn engine counter-clockwise if RR vs standard. JQ

------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: SNobsessed

Date Posted: February-14-2021 at 4:43pm

I believe he has RH rotation engine, so wouldn't he want to rotate CCW looking at front of engine?

------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: 8122pbrainard

Date Posted: February-14-2021 at 5:17pm

Did you get the proper rotation starter? What direction is the engine cranking? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KENO

Date Posted: February-14-2021 at 5:54pm

|

Way back in post #1 you said you replaced the starter and a few people have asked lately "did you replace the starter? You never really said that it's definitely the right starter though Ignoring any confusing or contradicting questions/advice about rotating things one way or the other way, answer this one question. I think you've already mentioned that the rotor goes counterclockwise, just want to verify that the starter makes it go that way.

With the distributor cap off, when you turn the key does the rotor turn clockwise or counterclockwise? That'll tell you everything you need to know as far as whether the engine is rotating the way it should be or rotating the wrong way. The rotor going Counterclockwise means it's the right starter and the engine is turning the right way. Clockwise means it'll never start cause the engine is rotating the wrong way and another correct starter might just solve your problem

|

Posted By: Jimscorpsewhale

Date Posted: February-14-2021 at 6:29pm

| It’s spinning counter clockwise for sure. |

Posted By: KENO

Date Posted: February-14-2021 at 7:36pm

And that's a good thing for sure

|

Posted By: KENO

Date Posted: February-14-2021 at 7:54pm

A non digital inductive timing light will work with no issues. You already know the digital one you have now works when the engine is running (it's not broken) Here's a good, cheap example with a dial type knob for the advance feature in the link below. The leads are a little on the short side but it works well. Or get your father in laws oldie, it'll work for you. http://www.harborfreight.com/timing-light-with-advance-40963.html?_br_psugg_q=timing+light" rel="nofollow - link Maybe try a shot of gas down the carb primary throats. and see if it kicks itself over with that little boost.

|

Posted By: Jimscorpsewhale

Date Posted: February-14-2021 at 8:32pm

| The weather here is a mess. I’ll have a oldie timing light maybe Tuesday. I’ll report back. KENO thanks for all your help. |

Posted By: KENO

Date Posted: February-15-2021 at 8:21pm

|

Jim Time for another question about fuel delivery, since you have spark  Way back in post #1 of this thread you mentioned installing an Edelbrock Performer intake. Did you ditch the 1 inch PCM spacer when you mounted the carburetor to the manifold or did you keep it between the carburetor and manifold? or in other words how is the carburetor mounted to the manifold?

|

Posted By: Jimscorpsewhale

Date Posted: February-18-2021 at 6:46pm

|

There is a spacer but not the original one. I used this one https://www.holley.com/products/fuel_systems/carburetor_components/carburetor_gaskets_adapters_and_spacers/adapters_and_spacers/parts/4945 |

Posted By: Jimscorpsewhale

Date Posted: February-18-2021 at 6:47pm

| I still don’t have the timing light yet. The weather is a mess |

Posted By: Gary S

Date Posted: February-18-2021 at 8:11pm

|

Pretty sure this is what Ken is thinking about. You could have a vacuum leak. https://www.amazon.com/Edelbrock-2732-Carburetor-Adapter/dp/B000630JXY/ref=asc_df_B000630JXY/?tag=hyprod-20&linkCode=df0&hvadid=309898128610&hvpos=&hvnetw=g&hvrand=7484433107131671709&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9011877&hvtargid=pla-569638733036&psc=1 ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: tryathlete

Date Posted: February-18-2021 at 8:17pm

| Vacuum leaks. I recall on my A&P troubleshooting test for the license, working on an A-65 Lycoming and the examiner hung the updraft carb about 1/4 off of the manifold. It started and ran fine. I saw what he’d done and pretended not to notice and we both started to laugh at about the same time. Neighed of us could imagine it would even start let alone run up fine. |

Posted By: Jimscorpsewhale

Date Posted: February-18-2021 at 8:56pm

| Ah. I put an new spacer and gasket on. I don’t remember finding any specific torque specs for the carb. I’m also not sure if there is a gasket between both the intake and the spacer and the spacer and the carb... what’s the correct setup? |

Posted By: KENO

Date Posted: February-19-2021 at 7:24am

Is your Mr Gasket spacer smooth on the bottom like is is on the top, or does it have funny passages like your old original spacer? If you're not sure, take the carburetor and spacer off and look at it. (and take a picture to post here) You should have a gasket between the intake and the spacer and another one between the spacer and the carburetor. You could have a giant vacuum leak depending on your gasket arrangement and what the bottom of the 1 inch spacer looks like What works good on the Performer intake is using the flat plate like Gary mentioned with no 1 inch spacer at all. The plate is needed because of the small, thin seating area on the Edelbrock 2181 manifold. You would have a gasket between the manifold and the flat plate and another between the plate and the carburetor. The PCV hose connection can then be plumbed into the threaded hole in the manifold behind the carburetor. You remove the pipe plug and get a fitting for the hose to hook to. It's in the runner that feeds the #4 and 7 cylinders. Some people will say that the PCV gases going there will lean the mixture to those 2 cylinders, some will say no problem at all, Plenty have run that way for years with no issues  It keeps the height down also when you don't use the 1 inch spacer. The Edelbrock manifold is around an inch taller than the stock one so your height is about the same as original Before worrying about this stuff though, try starting it with a shot of gas down the primary throats like mentioned earlier so see if it kicks over and runs meaning that your timing is at least close to where it should be. When Mother Nature allows of course

|

Posted By: Jimscorpsewhale

Date Posted: February-19-2021 at 4:10pm

|

I have some home repair that’s gonna trump the boat this weekend due to the ice. I’ll definitely put some gas down the primary throats in the carb before I do anything else. A “shot”. Literal measurement? |

Posted By: KENO

Date Posted: February-19-2021 at 7:13pm

|

See the little yellow cap on the spray can, about that much gas is good and it should fire. You might have to repeat a few times or so to get the fuel system primed so it'll stay running. I use my finely calibrated fingers and a plastic squirt bottle to squirt about that amount in the carburetor   |

Posted By: 8122pbrainard

Date Posted: February-19-2021 at 7:42pm

Along with Kens calibrated fingers, one of these works great: ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: Jimscorpsewhale

Date Posted: February-27-2021 at 3:39pm

|

So I have the timing real close. I used the camera on my phone in slo mo while I was cranking and I am right at 6 degrees btc. I put some gas down the primary jets and it seems like it’s trying to kick over. I get some intermittent bumps in the cranking speed that I think indicate it’s getting some help from the engine kicking over. I haven’t pulled the carb yet to look at the spacer. It’s mr gasket 4945. I have gaskets on both sides. From the images I can find online i don’t think it has any passages but I can’t be sure. I had to put it away this afternoon as it started raining. I think I’m close any other suggestions are highly appreciated. |

Posted By: Jonny Quest

Date Posted: February-27-2021 at 5:43pm

|

Dang. That sure sounds like the dizzy is 180 degrees off. At 10 degrees BTDC, it should fire right up...quickly. JQ ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: Jimscorpsewhale

Date Posted: February-27-2021 at 5:45pm

| I put a compression gauge on it and as the rotor came to the number one cylinder fire position I was making compression |

Posted By: KENO

Date Posted: February-27-2021 at 6:11pm

|

How about spitting out your firing order going counter clockwise around the cap? Just want to verify what you have. Kinda like a quiz

|

Posted By: Jimscorpsewhale

Date Posted: February-27-2021 at 7:12pm

|

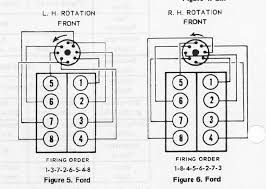

I went out just now and ran them to be sure. 1-8-4-5-6-2-7-3 |

Posted By: Jimscorpsewhale

Date Posted: February-27-2021 at 7:13pm

| To be sure we are speaking the same language. The front of the starboard bank is one right? |

Posted By: KENO

Date Posted: February-27-2021 at 7:24pm

|

Congrats, you passed the quiz and here's the cylinder numbering for the 351W   |

Posted By: Jimscorpsewhale

Date Posted: February-27-2021 at 7:44pm

| So I guess I should pull the carb and check the spacer? It’s a mr gasket 4945. I don’t think it has any passages but I’m not too sure. I definitely have gaskets at both mating surfaces. Anything else i should check or try? |

Posted By: KENO

Date Posted: February-27-2021 at 7:53pm

| It's probably flat and smooth on both sides but it wouldn't hurt to check the spacer just to be sure there's not a vacuum leak path |

Posted By: SNobsessed

Date Posted: February-28-2021 at 8:15pm

|

Have you checked your fuel quality? Maybe you have water in it. That will keep an engine from running. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: Jimscorpsewhale

Date Posted: March-01-2021 at 5:47pm

|

I’m not sure how I would gotten water in it... it’s been in the garage all winter. Is there any easy way to test for it? I was thinking about adjusting the idle screw and the idle mixture back to how they suggest it’s set during initial install.... |

Posted By: tryathlete

Date Posted: March-01-2021 at 6:13pm

| Did you fill the tank? Did you add stabil or fuel stabilizer? If you leave a lot of room in the tank, as the air cools, moisture in that air will condense and sink to the bottom of the tank. Of course that’s where your fuel pickup is located and those first few draws to start the boat are fuel in the line but then it’s quickly fed that water you’ve condensed. Water in fuel causes carburetor icing in small recip aircraft which is why pilots sample their fuel (from the bottom of the wing tank) to make sure there’s no water there; which there often is. |

Posted By: Jimscorpsewhale

Date Posted: March-01-2021 at 7:09pm

| It’s got stabil in it but it’s not full |

Posted By: KENO

Date Posted: March-01-2021 at 7:56pm

I don't think I'd worry too much at all about water, unless you're dumping water down the carb throats to get it to kick over and run some  I think the first mention of how you have the carburetor adjusted just came today, so how is it adjusted? I also think that three pages later,with lots of detours, it's time for a quick synopsis of what's been done so far to the engine. I'll get you started, feel free to add anything else. It sounds like you put on gt40 heads, an Edelbrock 2181 Performer intake, a new carb spacer and new plugs and wires . You thought you didn't have spark, but you really did, at least with the new DUI distributor. You got a free replacement module from DUI  You verified the rotor spins CCW so the engine is turning the right way. Timing is now around 6 degrees BTDC and you can see this with the timing light as you crank it over. You're on the compression stroke You dumped some gas down the carb throats and it sounded like it was trying to start Did you do this a few times? Since you mentioned having a compression gauge, what do you have for compression in all your cylinders. Send me your video of the timing if you want keno439@gmail.com will get it to me |

Posted By: Gary S

Date Posted: March-01-2021 at 8:03pm

I'm with Ken -this thing is not even firing with gas dumped down the intake. It should fire that way even if there was no carb on it. Unless someone has changed all his gas in his cans and tank with water  ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: tryathlete

Date Posted: March-01-2021 at 8:12pm

| 100% agree |

Posted By: Jimscorpsewhale

Date Posted: March-01-2021 at 9:17pm

|

I pulled the carb off to look at the plate and in doing so I found something stupid I had done. The carb has a nipple on the back of it and I plugged the hose that goes to valve cover into it instead of into the spacer. That would give me a bad vacuum leak right? I'll put it back together right and give it another try. The spacer is almost entirely smooth with one area that has a little carve out with Mr. Gasket printed in it. Thoughts on keeping the spacer or getting rid of it?

|

Posted By: KENO

Date Posted: March-02-2021 at 12:16am

|

Yes on the vacuum leak. Your studs are the right length for the spacer so stick with it as long as the plate is flat on the bottom too. Probably 1/8 inch pipe threads in the spacer hole. Plug it with a 1/8 inch pipe plug preferably or cover the nipple with a rubber or vinyl cap Then give it a whirl  PS timing video looked good

|

Posted By: Jimscorpsewhale

Date Posted: March-02-2021 at 6:27am

|

Thanks for checking the video. The other side to the spacer is completely smooth. The original set up had the hose that runs to the valve cover plumbed to the fitting on a different spacer and the fitting on the back of the carb capped. Just curious but does it matter? Also the fitting where the hose enters the valve cover it rubber and pretty worn. I wonder if I should eventually replace the valve cover as well. |

Posted By: KENO

Date Posted: March-02-2021 at 7:36am

|

Either fitting will work, pretty much your choice of what to plug and what to use. The other end of that hose should have the PCV valve in it and the valve fits in your worn rubber fitting, it should be good for now to see if you get it running since it ran before the work was done

|

Posted By: Jimscorpsewhale

Date Posted: March-03-2021 at 8:09am

| Lots of the boat seems bonded by age/grime. The valve definitely seems far looser than when I broke it free from its mooring. I think it’ll be fine in the short term but it will likely need to be replaced. |

Posted By: Jimscorpsewhale

Date Posted: March-03-2021 at 8:23pm

|

Utter failure. The engine speed will intermittently increase like it’s trying to start. I put gas down the primary jets three or four times. I am still getting a spark per the inline checker. I plugged the vacuum port. Not too sure where to go from here. I ordered an adapter for the compression tester that looks like it will work with the gt40p heads. I’ll get some numbers if it works. Any other ideas are welcome. |

Posted By: MourningWood

Date Posted: March-04-2021 at 2:39am

|

Dang it... If it were me, I'd remove the right side valve cover. (when looking at the engine from the rear of the boat). Then remove the spark plug from cylinder #1. Rotate the engine manually and watch cylinder #1 valve rockers operating. When the piston is at the top of the cylinder after watching the intake rocker close (the rocker comes back up) you are at Top Dead Center at the firing position. Verify TDC with your timing pointer and dampener markings. Then pop the distributor cap and verify the rotor is pointing toward cylinder #1.

------------- 1964 Dunphy X-55 "One 'N Dun" 'I measured twice, cut three times, and it's still too short!" |

Posted By: Jimscorpsewhale

Date Posted: March-04-2021 at 7:16am

| Do you happen to know if on the gt40p if it’s the front or rear valve that’s the intake? |

Posted By: Slydog

Date Posted: March-04-2021 at 10:16am

|

Intake is at the front of the head. The exhaust port will align with the exhaust valve (rocker arm). ------------- Always looking for glass on the lake... Sly |

Posted By: Jimscorpsewhale

Date Posted: March-04-2021 at 12:48pm

| Makes sense. Should have been obvious.... |

Posted By: Slydog

Date Posted: March-04-2021 at 1:53pm

|

Many years ago a reputible marine shop in Florida sent me home with an incorrect starter for my 1988 SN. The '88 has a RH rotation engine as designated on the engine nameplate. I had limited tools and was working in a hotel parking lot. The boat would not run after the new starter was installed and it turns out I did not get the CCW starter I needed. I had similar syptoms to what you are describing here. "The engine speed will intermittently increase like it’s trying to start.". My engine would intermittently fire on a cylinder but not run. Having said that, it certainly sounds like a timing issue which could be caused by several situations. Incorrect starter Distributor installation or not for a RH rotation engine. ...etc..... These items have been discussed previously and just need to hammer out which. Somewhere I think you also talked about a compression test. Did I miss the results? You have fuel. You have spark. Need to ensure the spark is in time with compression and BANG! ------------- Always looking for glass on the lake... Sly |

Posted By: KENO

Date Posted: March-04-2021 at 4:24pm

|

Sly He has a RH engine and it's turning the right direction which he verified by the distributor rotor going the right way when the engine is cranking over and he says he's using the right firing order and the wires are arranged the right way going around the cap and he knows how the cylinders are numbered. You can verify what he's written earlier in the thread. He can't post a picture or video here for let's say technical reasons, but he sent me a super slo mo video of his timing light flashing with the timing at 6 degrees before TDC with the engine turning the right way, but that doesn't tell him it's on the compression stroke. People have been taking his word for that with his description of how he checked. If he does what Mourning Wood said, at least it'll tell if he's at 6 degrees before TDC on the compression stroke or maybe he'll find he's 180 out which sounds like it might be the case but he said it's on the compression stroke a couple of times already with a good explanation of how it was done. So for now the mystery continues At least he's fixed a few issues along the way PS I guess you probably weren't real satisfied with that reputable marine shop  |

Posted By: Jimscorpsewhale

Date Posted: March-04-2021 at 7:50pm

|

I am going to do what morning wood suggested this weekend as long as work doesn’t beat me to bad. Just to be sure. So pull the valve cover and spin the engine by hand. The #1 intake should open and right as it finished closing I’ll make sure that the pointer is lined up with tdc on the balancer and pop the cap and confirm the rotor is pointed at the number one cylinder. I drained the gas today.... I put some stabil in it when I got the boat but I’m not sure how long the previous owner had the fuel there. Also I drug it home six hours in the remnants of a hurricane so maybe it did get some water in it. I got a new fuel filter on the way as well. Can’t hurt at this point. |

Posted By: MourningWood

Date Posted: March-04-2021 at 8:43pm

Sounds like a plan... Remember, when the intake rocker has finished closing, the piston will still be down somewhere near the bottom of the cylinder. You'll have to rotate the engine some more (the compression stroke) and bring the piston up to the top of the cylinder before the pointer aligns with TDC. ------------- 1964 Dunphy X-55 "One 'N Dun" 'I measured twice, cut three times, and it's still too short!" |

Posted By: Jimscorpsewhale

Date Posted: March-04-2021 at 9:04pm

|

Is there anyway to assess the height of the piston through the spark plug hole? In theory the balancer could be off right? If it had moved then even if I am on the compression stroke then maybe I’m not actually at tdc when the mark says I am... I wish I had confirmed it was spot on when I had the head off. Lessons. |

Jimscorpsewhale wrote:

Jimscorpsewhale wrote: