Hot start problem

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=49661

Printed Date: January-16-2025 at 3:45am

Topic: Hot start problem

Posted By: adamo

Subject: Hot start problem

Date Posted: March-11-2021 at 9:07pm

| I have a 83 south wind 20 with the 351. It runs Awesome and starts good cold. It has a real hard time starting after it’s been run for a while. The carb does not leak anymore and it’s getting fuel. It has a new coil plugs and wires and rebuilt the distributor. The coil gets pretty warm but I am not sure what’s “too” hot? Or could the starter be drawing too much power? And if the coil is getting to hot wouldn't it stop working while I am running the boat not just after it sits? Thanks in advance |

Replies:

Posted By: SNobsessed

Date Posted: March-11-2021 at 10:17pm

|

The engine can get to a higher temp just after it is turned off, because the cooling water stopped flowing. You could test for spark when it fails to start. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: adamo

Date Posted: March-11-2021 at 10:19pm

| I will try that, if it is getting the coil too hot after shut off. What could I do to fix that? It seems to be getting worse |

Posted By: KENO

Date Posted: March-12-2021 at 7:16am

|

Does a hard time starting mean it turns over just fine but doesn't want to start? Do you have to give it some throttle when you're restarting it when hot? You had issues about a year ago that a float adjustment took care of, now you may have to do some "twiddling", AKA tweaking, on the idle mixture screws to get it to start better after it's hot..  See the link below for some info that might help http://www.correctcraftfan.com/forum/forum_posts.asp?TID=48605&title=hot-and-cold-starting-89-sn" rel="nofollow - link |

Posted By: adamo

Date Posted: March-12-2021 at 7:50am

| Yes it turns over good but it it just won’t fire. After trying and trying it always does . Could the idle mixture screw adjustment help hot start and not affect the cold start? And should I run it and then check for spark or you don’t think that’s an issue? Also I tried starting fluid last night when it wouldn’t start on the lake and it didn’t help at all, which doesn’t make sense? |

Posted By: adamo

Date Posted: March-12-2021 at 7:52am

| It seems to always start better when I take the air filter off as well when hot starting. |

Posted By: TRBenj

Date Posted: March-12-2021 at 8:06am

| Let’s take a step back... how about you walk us through your cold and hot starting procedures. |

Posted By: adamo

Date Posted: March-12-2021 at 8:35am

| First thing for hot start is I’ll turn the blower on and then turn the key and if it doesn’t start I’ll start adding throttle. Then if it doesn’t start I’ll take off the air filter and normally that helps. But recently I have been struggling and having to turn it over about 7 different times before it starts. For cold start I run the blower and it cranks up in 1-2 tries normally . |

Posted By: Jonny Quest

Date Posted: March-12-2021 at 9:04am

I recommend that you do NOT use starting fluid...particularly on a warm engine. Bad engine ju-ju. You can verify if the coil is producing a spark. Lisle makes specialty tools and such for the automotive industry and makes a decent, low-cost spark tester that is easy to use: Lisle 20610 Inline Spark TesterJQ

------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: adamo

Date Posted: March-15-2021 at 5:26pm

| I took the boat to the lake today and tested all plugs with the spark plug tester and they all showed getting spark. Even when cold and hot. While it was warm I tried to tune the carb and found out that if I shut both idle adjustment screws all the way in the motor still runs and the carb starts dripping. But when I shut it off the cards do not drip. Also as I was coming back I to the dock it wouldnt want to run at idle speeds, it kept wanting to die. This was before I tried to adjust anything. |

Posted By: KENO

Date Posted: March-15-2021 at 9:00pm

|

Based on your last post you may need to clean your idle air bleeds (and the main air bleeds while you're at it.) There are pictures in the link below of the air bleed locations on a Holley. The outboard holes are the main air bleeds and the inboard holes are the idle air bleeds. You might as well do all 8 of them with spray carburetor cleaner and compressed air. (4 on the primary side, 4 on the secondary side, all shown in the picture). It can also be done with the carburetor apart blowing in the other direction, internally to external, but this is easy and usually works. Like the writeup says, you can do it in place, then I'd set the idle mixture screws out about 1 1/2 turns as a starting point and do the previously mentioned "twiddling" to be sure you're idling on the idle circuit. If no luck, you'll have to take the front bowl and the metering block off and make sure all those tiny passages associated with the idle system and it's air bleeds in the metering block and carburetor body are clean and blown out. Having rebuilt it last year, I don't know if you might have blown out the air bleeds or not. Lots of people never go near them Somebody is bound to jump in and say that isn't a marine Holley 4160, but that OK, the pictures are only to show where the air bleeds are located.  As far as the guys thoughts on ethanol, everybody has thoughts, not all the same. You could have other issues but this is a cheap easy start.

|

Posted By: adamo

Date Posted: March-16-2021 at 12:17pm

| So the motor should not run when the idle mixture screws are turned all the way in right? I had it in gear at about 1000 rpms and as I was looking at the carb it went from spraying a mist to dripping from higher up as I closed the mixture screws. |

Posted By: KENO

Date Posted: March-16-2021 at 3:57pm

You're right.........it shouldn't run at idle speed, but 1000 rpm isn't exactly a good, normal idle speed either  So you need to back up a couple of posts and do the cleaning mentioned. At 1000 rpm in gear, you're drawing most of your gas from the transition slots and not the idle circuit, so closing the idle mixture screws makes no difference. So if you clean things like the air bleeds, then with the idle mixture screws about 1 1/2 turns out as a starting point try setting your idle down to 650 to 700 or so in neutral and tweak for a smooth idle adjusting both the mixture screws and speed screw as necessary to maintain the low idle speed.. When that's good, you can put it in gear in the water and the idle should drop maybe 50 to 100 rpms and idle smoothly. You can then tweak on the mixture screws for the best smoothness and see how it responds. Like mentioned before, you could have other issues, but try this first before the other stuff gets discussed Can you make it idle at that 650 to 700 rpm speed right now or is 1000 as low as you can get it to "idle" At a normal idle speed with fuel being supplied by the idle circuit you should be able to look down the throats and see no gas because all the gas is going into the engine under the throttle plates which are barely open.

|

Posted By: adamo

Date Posted: March-16-2021 at 4:05pm

| Sorry I wasn’t clear with the 1000rpms, i read I was supposed to adjust the mixture screws at 100-1500 it that does not seem right now thst I think about it. it idles at about 700 and drops a little when in gear. I cleaned all 8 of the air bleeds and now the idle mixture screw actually affects the motor a lot. I adjusted it on the trailer and it starts 10 times better. I’ll take it to the lake and try it out but so far it’s way better. When I’m on the lake, should I adjust it at idle and then in gear as well? |

Posted By: KENO

Date Posted: March-16-2021 at 5:11pm

You're on a roll now  Try it just the way it is and see how it responds when you put it in gear, you might have to open up the idle mixture screws slightly or it may be just fine

|

Posted By: adamo

Date Posted: March-16-2021 at 6:19pm

| I tried it in the water and turned it up a 1/4 turn and seems to be better. It’s not perfect as it takes a little throttle to get it started but it’s starting every time much more consistent. Thank you very much for all the help. |

Posted By: adamo

Date Posted: March-21-2021 at 4:15pm

| Took the boat to the lake and it wouldn’t. I took it home and put a jump wire on the ballast resistor and it fired right up. The coils is getting 5 volts when the key turned on and 2.5 when the starter is engaged. Is there supposed to be a jump wire for the resistor when starting? Or is my starter drawing to much power? |

Posted By: 8122pbrainard

Date Posted: March-21-2021 at 4:59pm

|

Adam, No, they didn't use a ballast bypass during cranking on your engine. The voltage readings you are getting are very low. What are you getting at the battery? Then a reading at the ignition switch, then at the balleast resistor and finally at the coil. You should have 8 to 9 volts at the coil. Report back to what you find. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: adamo

Date Posted: March-21-2021 at 5:01pm

| I am getting 5 volts at the coil before I try to start, and about 10 at the resistor. And 12 at the battery |

Posted By: 8122pbrainard

Date Posted: March-21-2021 at 5:08pm

Adam, How are you checking volts at the coil? Disconnect the negative wire and check again. Also, as mentioned, check for a drop at the ignition switch. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: adamo

Date Posted: March-21-2021 at 5:29pm

| I disconnected it and it’s getting 12 at the coil from the disconnected negative wire to the connected positive wire. Where should I put the negative wire of my multimeter |

Posted By: KENO

Date Posted: March-21-2021 at 9:36pm

I don't think you've said that you have points under the distributor cap, but assuming that you do, the 10 volts at the resistor input side and 5 at the coil (+) is not a bad reading if the points are closed when you check the voltage. If the points were open you'd have the same number at the coil (+) and the resistor input since the coil is doing no work.. In your case 10 volts at both. If you unhook the negative wire at the coil(and the gray tach wire too for good measure, like Pete mentioned, then check the voltage on the coil (+), it should be about the same 10 volts at both spots since the coil is doing no work. The 10 may be a little low and that's why he said to check the voltage at the key switch terminals (and check the connections tight too). Then you could unplug the 8 plug connector at the back of the engine and check all the plugs clean from corrosion or clean them up to be sure you're not losing some power there. And.........PCM didn't use a bypass like mentioned, but it would be easy to wire and give you the best possible voltage to the coil when starting the boat. You would run a wire from the "I" terminal on your start relay/solenoid to the coil (+) terminal and when the key is in START, you get full voltage with a short direct path going to the coil. After the engine starts and the key is now in the RUN position, the "I" terminal has no power supplied from the solenoid so it supplies no power to the coil, but the coil is getting power from the normal path from the keyswitch to the ballast resistor to the coil and with the alternator now running you have more voltage to the resistor and the coil. Click on the link below for some talk about this jumper (affectionately known as the Zach Jumper  ). ).It just automatically does what you did with your manual jumper. You can call it a band aid or whatever for a voltage issue in your wiring but it's easy and as you showed with your temporary jumper, it makes your engine start There's really no down side to doing it, you could find and cure your voltage issue. and decide to leave the jumper installed. And if you happen to have an electronic module hiding under the cap, all this stuff still pertains. If you want a drawing for installing this jumper, just say so and one will magically appear tomorrow  http://www.correctcraftfan.com/forum/forum_posts.asp?TID=47003&title=no-start-no-luck" rel="nofollow - link

|

Posted By: adamo

Date Posted: March-21-2021 at 9:51pm

| I would love a diagram thank you very much! |

Posted By: KENO

Date Posted: March-21-2021 at 10:04pm

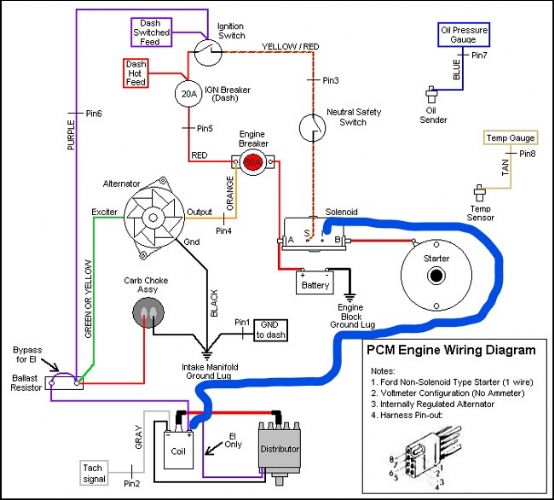

This is a mid 80's diagram courtesy of TRB, which may be a little newer than yours but you have a solenoid and a coil just the same, so adding a wire as the blue squiggly line shows would accomplish the "Zach Bypass"

12 gauge is a good wire size for this 12 gauge is a good wire size for this |

Posted By: tryathlete

Date Posted: March-22-2021 at 12:46pm

| Ahh CCF. What will the world ever do without it. |

Posted By: adamo

Date Posted: March-29-2021 at 3:10pm

| I have taken it to the lake and it starts up perfectly every time. The only thing I am noticing now is when I’m idleing in gear after a couple min it sounds like it starts missing and stalls out. But idling out of gear it doesn’t seem to miss a beat. And when it does stall out it starts right back up easily. I need to still clean the 8 point connector in the back, any advice on how to pull it apart without breaking? |

adamo wrote:

adamo wrote: