Shaft Alignment Question

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Boat Maintenance

Forum Discription: Discuss maintenance of your Correct Craft

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=49732

Printed Date: January-15-2025 at 9:54pm

Topic: Shaft Alignment Question

Posted By: TG3

Subject: Shaft Alignment Question

Date Posted: April-08-2021 at 11:03pm

|

My 97 Sport didn’t have the oil drain hose, so I bought the kit from nautiqueparts.com, and used a little bottle jack to slightly raise the one side of the motor to allow me to install the hose. I found some threads here about shaft alignment and also a YouTube video on it. As I understand it there is supposed to be a gap in the coupler (where the green arrow is pointing) to check with a feeler gauge. Mine appears to have no gap. Am I missing something?  ------------- 1997 Air/Sport Nautique |

Replies:

Posted By: Jonny Quest

Date Posted: April-09-2021 at 12:18am

|

Take the 4 bolts out and separate the couplers. When you bring them back together you check to see if the mating surfaces are within 3 one-thousands at 0, 90, 180, and 270. You also need to see how the shaft is centered in the log. Good time to repack the stuffing while you are at it. JQ ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: KENO

Date Posted: April-09-2021 at 5:45am

|

You mention seeing a video, but not which one, if you click the links below, you'll maybe get your question answered http://www.youtube.com/watch?v=3_w0LvD6gEc" rel="nofollow - link http://www.youtube.com/watch?v=5UqniaiggKA&list=UUSHOLmJXRsWifyZKB9aR4jA&index=42" rel="nofollow - link http://www.youtube.com/watch?v=UEqzJgCz_6w&list=UUSHOLmJXRsWifyZKB9aR4jA&index=41" rel="nofollow - link |

Posted By: 8122pbrainard

Date Posted: April-09-2021 at 7:28am

Trey, You missed what is being done with the gap. The gap is ONLY there when you are measuring for parallelism between the coupling faces. The engine is moved in any direction so the max difference side to side top to bottom is .003". This assures the prop shaft is aligned with the engine. After you get the max of .003" the coupling halves are tightened. Take another look at one of the videos Ken linked. Also as JQ mentioned, the prop shaft should be centered in the log. One other item on alignment is the shaft should also rotate freely in the cutlass bearing in the strut. Considering you moved the engine, I highly recommend a complete check for alignment.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-09-2021 at 8:58am

|

Thank you guys. I will take a look at these video this evening. I am pretty sure I need replace the cutlass bearings too, If I grab the prop end of the shaft I detect about an 1/8" of up/down/side to side play. As I understand it there should be no play, right? I bet these videos will answer another question I had about how to remove the shaft itself. I will also search up the forum and YouTube for some repacking videos. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: April-09-2021 at 9:20am

|

Trey, Yes, you shouldn't be able to feel any shaft movement in the cutlass. On the removal of the coupling half off the prop shaft:

Using find thread bolts and never seize will make it go easier.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-09-2021 at 10:38am

|

Thank you Pete! ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: April-09-2021 at 11:10am

|

TG Multiple opportunities await you  You're gonna have the opportunity to learn how to take the coupling off your straight shaft with an interference fit as already mentioned. Then you'll have the opportunity to learn how to remove the rudder so you can slide the shaft out Then you should look at the rubber hose connecting the shaft log to the stuffing box because it's the ideal time to replace it if it looks old,ugly and cracked etc. And then the opportunity to learn how to put that interference fit coupler back on the shaft which isn't any fun at all. There are ways to make life easier by installing a double taper shaft but that comes with a price (new shaft and coupling). Then reinstalling the rudder and deciding if you want to repack it at the same time. I'd do lots of homework with searches here on CCF and elsewhere. Some people might remove the rudder, leave the shaft alone and remove the strut to do the bearings, then reinstall the strut and do an alignment check. It avoids the shaft coupling removal and install issues You don't get the opportunity to replace the hose between the stuffing box and the packing gland though  Edit, based on a thought by Wetskier 2000 in a different thread, you could leave the rudder in place, unbolt the coupling halves and should have enough wiggle room to move the shaft enough to get the strut past the rudder. |

Posted By: TG3

Date Posted: April-09-2021 at 2:33pm

|

Ken, how lucky I am to have these opportunities! Seriously, thanks for the run down. I will do some research and see what I am about to get into. ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: April-09-2021 at 6:33pm

You sure are  With the amount of slop you have, it's a good thing to take care of it now though.

|

Posted By: gun-driver

Date Posted: April-09-2021 at 9:41pm

|

Luckily you have a Sport which makes dropping the rudder so much easier than a Ski Nautique. On my '95 SN I found it easier to drop the strut instead of removing the gas tank to get to the rudder.

|

Posted By: TG3

Date Posted: April-12-2021 at 11:37am

|

I appreciate all the help and the great info posted on this forum. I have done a lot of reading and watching this weekend on all the parts of this job. There was a great post by John (Foot Fungus) about the coupler and options for replacing. Rob (Jonny Quest) sent me his phone number and spent and hour on the phone with me talking through his experiences, which was very helpful. So my plan of action is to replace the shaft and coupler with the double taper system, replace the cutlass bearings, repack the stuffing box and add a safety collar to the shaft. While doing all this I'm going to very carefully and patiently check all the alignments to make sure it is straight and true. Now to start spending money amassing parts! ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: April-18-2021 at 9:22pm

|

Today I removed the prop and cut the old shaft to remove and measure it so I could order a new double taper shaft (and strut bearings, packing etc....) The shaft hits the rudder, which is logical and i expected to happen. Before I research how to remove/reinstall the rudder, I thought I would ask if there is any trick I’m missing to get the shaft out without removing the rudder. If I have to remove the rudder, any tips (or links) you would recommend? I’ll search the site and the inter web/YouTube etc as well.

------------- 1997 Air/Sport Nautique |

Posted By: SNobsessed

Date Posted: April-18-2021 at 9:59pm

|

Either have someone underneath catch as it falls (when that nut comes off) or maybe have a floor jack holding it up until you get down from the bilge. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: TG3

Date Posted: April-18-2021 at 11:36pm

|

And do I have to pull the tank (that is full of 28 gallons of fuel) or can the rudder be dropped and repacked by reaching under? It looks like it would be tight, but could be done? ------------- 1997 Air/Sport Nautique |

Posted By: gcam4

Date Posted: April-18-2021 at 11:37pm

| I just put some wood underneath the rudder and loosened it some and kept checking it to make sure it wouldn't fall out. The hardest part of the rudder is getting the safety wire back on it! |

Posted By: TG3

Date Posted: April-25-2021 at 1:49pm

|

I have all the parts collected and I’m starting work today. First problem - Strut bearings - The set screws are jammed up tight and can’t get them out. I remember reading somewhere that you can drill them out and then re-tap the holes and put in new set screws. Anyone have a recommendation on what kind of setscrews I should buy? Should they be brass or stainless steel? ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: April-25-2021 at 2:01pm

|

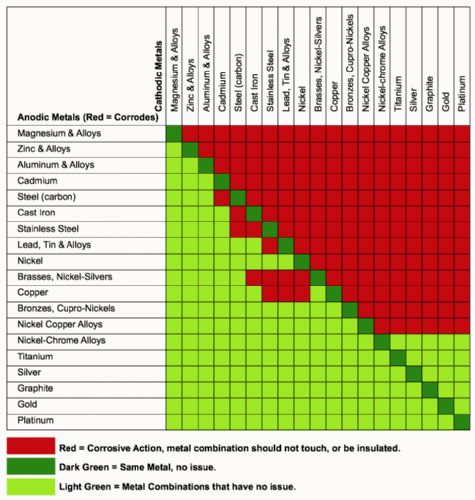

Trey, Stainless will be easier to find. I've never had a problem with them being a dissimilar metal but, I'm in fresh water. If you do get into salt or brackish It may be good to look for brass. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-25-2021 at 2:22pm

|

Thanks Pete. Only salt water here so I’ll go with Stainless. Maybe Lowe’s will have them and I can finish today. ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: April-25-2021 at 3:05pm

Let's see..........Pete says using stainless is OK in fresh water but in salt or brackish water brass is better.(for galvanic corrosion reasons) So you say you're in salt water and you're gonna use stainless. Something's wrong here  Maybe you meant to say "no salt water here"

|

Posted By: TG3

Date Posted: April-25-2021 at 3:19pm

|

Oops! I did mean FRESH water only. Thanks! ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: April-25-2021 at 6:23pm

|

Is the length of the rubber hose between the log and the packing gland critical? My old one measures 3 1/2”. The new piece I bought came in 4” length. Do I need to trim it to 3 1/2”? ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: April-25-2021 at 6:36pm

|

Trey, As long as there's room between the packing gland, the safety collar and the shaft trans coupling, there's no problem. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-25-2021 at 6:42pm

|

Thanks Pete! ------------- 1997 Air/Sport Nautique |

Posted By: Gary S

Date Posted: April-25-2021 at 6:49pm

The only salt Pete comes across is whats on his Margarita glass or the stuff they use on his street 10 months a year  Oh look here's a picture of the tiller assembly on a boat that just spent 8 years in salt water- it's got stainless! It is my understanding is that brass is not good in saltwater- bronze is preferred. I was warned by the Shamrock guys that people use brass water intake fittings because they can go to their local hardware store an buy them rather than use bronze which is more expensive and harder to find. I think it's the zinc in the brass that acts like a sacrificial anode and starts dissolving. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: 8122pbrainard

Date Posted: April-25-2021 at 7:26pm

Bronze and stainless are good together. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KENO

Date Posted: April-25-2021 at 7:38pm

I can think of a couple of reasons why you might want to consider shortening the hose to the original length of 3 1/2 inches One is that if you want to repack the shaft in the future sometime, it's nice to have all the room you can to slide the gland nut forward so you can pick out the old packing and put new stuff in Another is that with your double tapered shaft, if you want to remove the coupling at some time in the future, you need a tool to do it. Depending on the brand of shaft and coupling there are different tools and methods, but having all the space you can will make things easier. You may have a country mile of space with the 4 inch hose, but a country mile and a half inch just might make life a lot easier in the future

|

Posted By: TG3

Date Posted: April-25-2021 at 10:16pm

|

Good advice Keno, I’ll get my extra 1/2”. So here is the next question, which is finally coming back around to my post title. I have the new strut bearings installed. I slid the new shaft into place to check if it was centered in the log. It is not. The shaft is off center to the starboard side and down. It is not touching the log, but definitely not in the center. I slid the shaft all the way up so that it touched the transmission coupler, and the over and down is apparent there too. I did some measuring and the shaft is approximately 17/64” off center at the log. That’s just under 1/4”. Watching some videos from Ski Dim and Ron Tanis, I don’t think it has to be perfectly centered, but surely closer than what I have now..... One thing puzzles me. When I uncoupled the old shaft, I don’t remember it dropping down and over, which it should have done and more so, considering the worn bearings. I inspected the strut and it appears to be straight, with no visible bends or damage/scraps to indicate that it may have been hit. When you look at the depression in the hull where the strut is bolted through, the strut is shifted to starboard, not centered in the depression, corresponding with the offset position in the log. What is the next step I should take to get the shaft more centered in the log? ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: April-26-2021 at 6:02am

|

When you uncoupled the old shaft, you probably still had the packing nut tight and helping to hold the shaft up. It sounds like now you just slid the shaft through for a quick check and there's nothing tending to hold it up. It also sounds like that's probably why your bearings were so worn and what is it that Pete always says......."alignment starts at the strut". I'm figuring he'll be along to tell you that the strut should come off so it can be moved enough to get the shaft pretty well centered in the log. PS you Texans must have longer inches than the rest of us. I guess everything really is bigger in Texas

|

Posted By: 8122pbrainard

Date Posted: April-26-2021 at 7:14am

|

Trey, The centering of the shaft in the log doesn't have to be perfect but the 1/4" is more than I would feel comfortable with. Also, the 1/4" puts the shaft very close if not actually touching the log. You mention the strut doesn't look bent but it's tough to see by just a visual. At one time it may have been installed incorrectly too? The solution is removing the strut, cleaning it and the hull up and then refastening it aligned. Port to starboard alignment of the strut can be done with the slop/clearance of the mounting holes/bolts. Minor up and down is down is done with washers between the strut base and the hull. In your case to raise the shaft at the log, you would put the washers at the aft holes. Dry fit the strut to cleck the alignment first. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-26-2021 at 7:55am

|

Thanks guys. And I need to correct my math (it was late last night when I calculating). It isn’t a 1/4” off center, more like .1” or just over 3/32” at the log. Still way to far judging by where the shaft touches the coupler. I will pull the strut and realign it and hopefully that will do the trick. Once I have it strut dry fit where I want it, I mark the position somehow and re-bed it in the 3M 4200 or 5200? I think I stumbled across that part in some other thread..... ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: April-26-2021 at 8:08am

|

Trey, Once you know the washers work for the up down and there's enough bolt hole clearance for the side to side during the dry fit, go fot the bedding. I suggest using 3M 4200 for bedding. Remember to take the weight off the forward end of the shaft when checking for shaft rotation in the cutlass. Some will rest the forward end of the shaft in a V block of wood. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcam4

Date Posted: April-26-2021 at 9:05am

For what it is worth I successfully tweaked my strut back and it was very similar to yours. I've been meaning to put together a thread detailing that, but I just haven't. It is on the to do list. It is very easy with a big crescent wrench and a 20ft piece of pipe to do so.

|

Posted By: TG3

Date Posted: April-26-2021 at 9:31am

Grant, please elaborate! Pete, I'll order up some 4200 and search the forum for application, I know I have seen that somewhere. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: April-26-2021 at 10:10am

Grant, I too have seen the method but, I've also seen where the bedding bond was broken causing a leak at the strut. These were however on older hulls where 3m 4200 or 5200 wasn't used. Trey, I highly recommend removing the strut. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcam4

Date Posted: April-26-2021 at 10:20am

|

Trey, I will try to get a picture tonight of how I did it. If you haven't already done so, drop your rudder so you can gain access easier back there. Before:  |

Posted By: gcam4

Date Posted: April-26-2021 at 10:23am

Pete, yep I was worried about that too. I haven't had any issues though, which is a good thing. I was willing to risk it though. Trey, as Pete mentioned, the best method is to pull the strut.

|

Posted By: TG3

Date Posted: April-26-2021 at 12:07pm

|

Ok, I am planning to pull the strut tonight. Once the strut is off the boat, is it possible to measure or gauge it somehow to see if it is bent? ------------- 1997 Air/Sport Nautique |

Posted By: gcam4

Date Posted: April-26-2021 at 12:13pm

I doubt anything is wrong with it. If you plan to pull it, do as Pete instructs and move it. You are likely off fractions of a degree. |

Posted By: TG3

Date Posted: April-26-2021 at 12:19pm

Ok, thanks! ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: April-26-2021 at 1:02pm

|

I can't get my head around the block of wood to support the shaft. Couldn't that interfere with getting the shaft centered while trying to align the strut by artificially positioning the shaft? Sorry for being dense, would y'all mind walking me through how I set the block of wood and coordinate it with the alignment of the strut? ------------- 1997 Air/Sport Nautique |

Posted By: gcam4

Date Posted: April-26-2021 at 1:14pm

| Trey, before you pull the strut, put the shaft back in. When you pull it closer to the transmission, spin it by hand. Then slightly pull up on it and spin it again. Basically the only thing the block does is support the shaft and to make it be the most concentric thru the strut. You basically move the wood around until the shaft is happy in the strut. There is not science to it necessarily, it is just feel. You'll want a piece of wood when you get the strut aligned again and likely while you are aligning it. The shaft will naturally want to move due to gravity and it will look low in the log without it being supported. Just try it before removing it so you can get a feel. |

Posted By: TG3

Date Posted: April-26-2021 at 2:11pm

|

Thanks Grant, that makes sense to me now. ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: April-26-2021 at 10:14pm

|

Ok, I got the strut off. It wasn’t easy, but not as hard as I have read in some other threads. The sealant was very rubbery, and didn’t look as old as what was around the rudder port, so I’m guessing that the strut has been messed with in the past. I trimmed as much of the sealant away with a razor blade, then tried tugging on it. I found some of Pete’s wisdom in another thread that suggested using a heat gun, so I did that. I pulled real hard and it popped off. Immediately following its release, my face stopped the strut from hitting the ground. Ouch. Now i have a huge knot on one of my cheekbones. I carefully scrapped as much of the old sealant as possible off the hull. Is there anything I can use, like a scotchbrite wheel in a drill that will take that off without damaging the gel coat/fiberglass? ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: April-27-2021 at 5:59am

|

I wouldn't worry too much about the gel coat. You will be putting a new layer of bedding down and actually, you what the gel to be roughed up anyway. The Scotchbrite wheel isn't a bad choice. What color was the bedding used you are removing? ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-27-2021 at 8:27am

Ok, that will make it easier to get the rest off. The bedding was very white. It had a smooth, rubbery texture. ------------- 1997 Air/Sport Nautique |

Posted By: SNobsessed

Date Posted: April-27-2021 at 5:18pm

You can put on a flat surface & sight it against a square for comparison. Look at it from both front & rear ends. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: 8122pbrainard

Date Posted: April-27-2021 at 6:52pm

Chris, Sorry but I disagree. Typically the only machined surfaces on the strut is the bore and the bottom of the base so a square isn't going to tell you much. I wouldn't even trust the four holes in the base. The only consistent is the angle between the bore and the base and the height of the bore to the base.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: April-28-2021 at 8:10am

|

Its going to be a couple more days before I can get back on this project. In the meantime, I was thinking, which is usually dangerous. Has anyone ever used a bore sighter for a rifle to align the shaft? ------------- 1997 Air/Sport Nautique |

Posted By: gcam4

Date Posted: April-28-2021 at 8:18am

I believe they use them now to get the log in a better location in the hull. That is the only thing I can think of that it would be useful for. You need alignment within 0.003" preferably less. |

Posted By: TG3

Date Posted: April-28-2021 at 8:19am

|

I retract that last post. The laser sight wouldn't help get me centered in the log because you can't see the laser beam, only the dot on the the transmission coupler. Unless.....I put a little piece of wood flat against the face of the log on the transmission side of the log, then I could see if the dot was centered. Maybe? Or waste of time and I should just do as you described with the shaft and the block of wood and quite trying to be fancy? ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: May-02-2021 at 9:41am

|

I dry fit the strut yesterday. I got it lined up in the center of the log. It wasn’t necessary to shim it for the vertical alignment. I used the block of wood as suggested, slid it under the transmission end of the shaft until it gave support but the shaft still turned without binding. If it quits raining I’m going to try to get it bedded/sealed after church today. I made some marks on the bottom of the hull with a sharpie so that I can put the strut back in the same spot. Any tips on the bedding? I have a caulk gun size tube of 3M 4200 so I think I will have plenty of sealant. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-02-2021 at 10:21am

|

Trey, I think you'll have enough 4200 to bed over 10 struts!  Don't completely trust your sharpy marks. As you are thightening up the stut mounting bolts frequently check the shft for center and free to move in the cutlass. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: May-02-2021 at 12:58pm

I knew I should have bought the 3oz tube instead! Oh well. I will make sure I check alignment often as I tighten up the bolts. ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: May-02-2021 at 8:07pm

|

Strut is aligned and bedded! What a pain, I hope I don’t have to do that again for a long time! Thank y’all for all the help with this part of the job. Should 24 hours be enough time for the bedding to dry before working on the driveshaft install and alignment? ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-02-2021 at 8:22pm

24 should be good to set the 4200 but I'd give it another 24 before getting the boat out on the water. 4200 is a moisture cure polyurethane so spraying water on it will speed up the cure. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: May-02-2021 at 8:31pm

|

Ok. I probably won’t get to the lake until this weekend. Just wanted to make sure I didn’t mess anything up installing the drive shaft tomorrow evening. Thanks Pete! ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: May-03-2021 at 7:58pm

|

Shaft is in the boat, gland nut (no packing yet) and safety collar on the shaft. I followed the guidance in Pete’s and Ron Tanis’ videos and checked the alignment. I understand i am looking for a difference in the measurements of no more than .003”, side to side, top to bottom. Measurements are as follows: .005” at the top, .004” at the bottom, so a difference of .001”. .006” starboard side, .004” port side, so a difference of .002”. This indicates that my motor is within tolerance of alignment, since my differences are no more than .003”. Did I get all this right? ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-03-2021 at 8:11pm

Trey, You got it!   ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KENO

Date Posted: May-03-2021 at 8:16pm

|

Done by the videos and those numbers says to me that you're good. I think Pete's kinda cute in his video

|

Posted By: TG3

Date Posted: May-03-2021 at 8:22pm

|

AWESOME!!! That makes me very happy, and very close to finishing!! Thanks guys! ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: May-03-2021 at 8:28pm

|

Remember all those "opportunities" mentioned early on in this thread? I think you're through them now

|

Posted By: TG3

Date Posted: May-03-2021 at 9:32pm

Well Keno, just one more opportunity! When i put the bolts in the coupler, they are a smidge too long, within .028” of the transmission bolts. Turns out the new driveshaft coupler is slightly thinner at the bolt flange then the old one. I know there wasn’t much clearance before, and the bolts don’t hit know, but that makes me very nervous. Since finding a bolt 1/16” shorter is probably impossible, I’m going to run by Lowe’s tomorrow and get some stainless washers. That thickness will put the bolts back to about the same clearance as they were originally. ------------- 1997 Air/Sport Nautique |

Posted By: gcam4

Date Posted: May-04-2021 at 6:23am

| Good work! |

Posted By: TG3

Date Posted: May-04-2021 at 9:35pm

|

Here is a little trick I discovered for a homemade coupler wrench. My Craftsman 1/2” drive break over bar has a hole in the end for hanging on the wall. It is the exact size of the coupling bolt, so I bolted it loosely to the coupling and it worked perfect to hold the shaft while I torqued the net down.  Sorry the pic is rotated sidewise, i couldn’t figure out how to make it straight.

------------- 1997 Air/Sport Nautique |

Posted By: Gary S

Date Posted: May-04-2021 at 11:05pm

|

Just one of the many reasons I got an Android phone and ditched the Apple... You did good thinking out of the box! ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: KENO

Date Posted: May-05-2021 at 6:28am

Because your Android has a hole in it for hanging it on the wall Gary?

|

Posted By: Gary S

Date Posted: May-05-2021 at 8:33am

|

Yes Ken. But not is all lost,you can drill your own hole in your iPhone you just have to start from the back. It then permantly fixes that pesky picture rotation problem as well. 🙂 ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: KENO

Date Posted: May-05-2021 at 8:57am

But, but, but............ I have an Android and my pictures sometimes come out rotated, funny thing is the only time it happens is here on CCF.  They go onto my computer just fine and magically decide to rotate (only sometimes and for no real apparent reason) with that wonderful picture posting feature here on CCF. Or about half of the time you get an error and have to do it over again after renaming the picture, just to get it to post at all. Post a picture showing where I need to drill the hole and the hole size too,

|

Posted By: Gary S

Date Posted: May-05-2021 at 9:46am

------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: KENO

Date Posted: May-05-2021 at 10:12am

Got it

|

Posted By: Gary S

Date Posted: May-05-2021 at 10:28am

|

Disclaimer- Ken keep in mind that this is not the headphone port modification! That is an entirely different operation see youtube for more info. I also have to admit that since I got the android I have not taken and posted pictures anywhere with it. Got so used to using my old camera that I just continue to do that. ------------- http://www.correctcraftfan.com/diaries/details.asp?ID=1711&sort=&pagenum=1&yrstart=1966&yrend=1970" rel="nofollow - 69 Mustang HM SS 95 Nautique Super Sport |

Posted By: TG3

Date Posted: May-07-2021 at 9:45pm

|

This may be my last question, the end is in sight. I was going to install the prop on my new shaft this evening, so I searched the site to find out what the torque spec for the prop nut is. I found Pete’s write up on lapping the shaft. So, is this a procedure I need to do with my new shaft? I really want to be done with this project and back on the lake, BUT i have taken this much time to get it all right, so if lapping is the right thing to do, I’m in. So, as i’’m sure Shakespeare would have said, “To lap or not to lap, that is the question!” ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-08-2021 at 5:44am

|

Trey, Yes, I highly recommend lapping. It's important especially when you have ether a new shaft, prop or both. Lapping will take out any minor differences in the matting surfaces of the taper. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KENO

Date Posted: May-08-2021 at 6:36am

|

So Trey Maybe it's not your last question  One answer might lead to another question One answer might lead to another questionYour next question should probably be ............."should I have lapped the coupling on the other end of my tapered shaft?" It's no different than the prop end of the shaft. It's not anything that's absolutely necessary on either the prop or coupling end, but fits more in the "good things to do" category. |

Posted By: 8122pbrainard

Date Posted: May-08-2021 at 7:56am

|

Regarding double taper prop shafts and the trans end taper, I've found two A.R.E's and one GP to not pass the prussian blue test and needed lapping. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: gcam4

Date Posted: May-08-2021 at 8:09am

| You should lap the prop in. I did mine off the boat which was a lot more convenient. I didn't do the trans end coupler. I didn't even think about it, but it makes perfect sense. |

Posted By: TG3

Date Posted: May-08-2021 at 8:50am

|

Thank you all! Ken, the opportunities keep on coming! I’ll get the supplies for lapping and get busy. I’ll pull the coupler and do that end too. That makes good sense. And since I haven’t reinstalled the rudder I’ll remove the shaft and do all this on the bench. ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: May-09-2021 at 6:47am

The opportunities abound  You have the opportunity to use your coupling removal tool, it looks like an ARE coupling you have and their tool works well especially in tight spaces like you have between the coupling and the transmission output flange in your picture below from when you installed the coupling  You also have the opportunity to wonder "why would somebody tell me that he highly recommends lapping the prop to the shaft but not even mention the other tapered end?" |

Posted By: SNobsessed

Date Posted: May-09-2021 at 7:57am

|

How many people have had the trans coupler prematurely come off of a ARE shaft? Or found it easily removed, for that matter? I would think, with both being machined at same shop, the tapers would match. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: TG3

Date Posted: May-09-2021 at 10:15am

|

When I ordered the shaft, I almost ordered the removal tool, but I thought “it will be awhile before I need that”. So I have one ordered now....! ------------- 1997 Air/Sport Nautique |

Posted By: KENO

Date Posted: May-09-2021 at 11:06am

In your situation, I wouldn't let the fact that I didn't lap the coupling bother me one little bit, but that's your choice  If ARE wanted it lapped ( or thought it needed it) they would have done it before they sent it to you or sent some lapping compound with the shaft and coupling.

|

Posted By: TG3

Date Posted: May-09-2021 at 4:52pm

I can agree with this logic. I am going to proceed with lapping the prop end and be done. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-09-2021 at 5:16pm

They should math but keep in mind the tapers are done on different pieces of equipment. They may consider the taper " close enough but as Ken mentioned:

Plus remember I found some that I didn't like looking at the prussian blue test.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: KENO

Date Posted: May-09-2021 at 8:07pm

We should probably quote my whole sentence Pete, instead of just part of it

|

Posted By: KENO

Date Posted: May-09-2021 at 8:11pm

Sounds reasonable to me considering that you wouldn't have even found out about lapping the prop end if you didn't go searching for torque values. And not lapping the prop isn't exactly the end of the world either.

|

Posted By: gcam4

Date Posted: May-09-2021 at 8:18pm

|

I remember now that I lapped the transmission end as well as the prop. It took about 5% of the time to do the transmission end. I would imagine they use the same lathe to do both, obviously with different tools though. I believe that is the reason why it was so quick for me to do. |

Posted By: TG3

Date Posted: May-14-2021 at 9:37pm

|

Everything is lapped up nice and and installed! Now I am reinstalling the rudder. It’s been a while since I disassembled it so how tight should that bolt on top that threads into the rudder be tightened? If I tighten it too much it locks up the steering so I’m thinking snug it up and that’s what the safety wire is for? ------------- 1997 Air/Sport Nautique |

Posted By: gcam4

Date Posted: May-14-2021 at 10:21pm

| Others may correct me, but you just want it tight enough so that it will not move vertically. It has a lock washer and safety wire to keep it from backing out. |

Posted By: 8122pbrainard

Date Posted: May-15-2021 at 6:09am

|

Trey, The bolt MUST be tight. If your steering is binding when you tighten it up, then you need a spacer washer on top of the rudder shaft. Spacers are added or removed depending on where the rudder port packing gland (nut) ends up after tightening it. The gland height will vari depending on how many wraps of packing is used, how tight it is as well as the type of packing. Did you just repack the rudder port?

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: rebel skier

Date Posted: May-15-2021 at 8:18am

|

Here is Trey's other recent thread on the rudder: http://www.correctcraftfan.com/forum/forum_posts.asp?TID=49758&title=rudder-packing-and-grease" rel="nofollow - https://www.correctcraftfan.com/forum/forum_posts.asp?TID=49758&title=rudder-packing-and-grease

Did you determine if that packing is the correct size? Pete, yes or no, use grease on the rudder with the gortex packing that he has in there? With my waxed rope install, I tightened down the nut with the new packing, went to the steering wheel and turned the rudder back and forth, hopped out of the boat and checked the rudder play, and then hoped back in and after spinning the wheel the nut more easily tightened more, so I added some turns till it felt tight, then repeat until there was minimal play in the rudder. ------------- Hotty Toddy lets go skiing! |

Posted By: 8122pbrainard

Date Posted: May-15-2021 at 9:13am

|

Richard, I feel that greasing a rudder port depends on the design of the port and not the type of packing used. As I mentioned in the other thread, the ports with seals are meant for grease and the ones with no seals no grease. If you grease a non sealed port, the grease will wash out in short order plus the grease may even trap contaminates like sand between the port bore and rudder shaft. Yes, the "Gortex" type packing is lubricated with PTFE but keep in mind the older flax type was also lubricated with a wax.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: May-15-2021 at 10:03am

I do have a spacer washer. The rudder was repacked recently by previous owner. It has three rings of the Gortex packing that look very good. (I completely forgot I had a rudder thread going!) No grease port on mine. It started to bind when I snugged it up. But I also Only tightened the gland nut until I felt like the packing was just starting to compress. Now that I think about it I tightened the steering Pitman arm first then the rudder bolt. I think that was the wrong order and could be putting things in a bind. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-15-2021 at 10:12am

|

Trey, Machining tolerance of ports and rudders are really sloppy plus how tight the packing compresses is another variable so, there are times when multiple spacers on top of the rudder shaft are needed. If the rudder moved freely before you removed it, there's a chance you didn't tighten the packing enough. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: May-15-2021 at 11:33am

That’s what I’m thinking. It moved freely before disassembly so I’ll go ahead and tighten up the gland nut some. Not having ever done this before I was being conservative with the packing. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-15-2021 at 12:16pm

|

Trey, Since a rudder shaft isn't continuatly turning and most of the time at a high RPM like a prop shaft, the rudder port can be tightened pretty tight. Snug up the gland and I'll bet the extra clearance will free up the rudder.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: TG3

Date Posted: May-15-2021 at 3:04pm

|

That did it Pete. Tighten down the gland nut and then the rudder bolt tightened up and the rudder still turns freely. ------------- 1997 Air/Sport Nautique |

Posted By: TG3

Date Posted: May-15-2021 at 10:21pm

|

We just got back from a 2 hour ride around the lake (after adjusting packing, etc). All was good! No extra vibration that I could tell. As part of this project I replaced my 2 bilge pumps, so that system is working now like it should. THANK YOU ALL FOR YOUR HELP!!! I couldn’t have done this without all of your contributions and answers to my questions. ------------- 1997 Air/Sport Nautique |

Posted By: 8122pbrainard

Date Posted: May-16-2021 at 5:32am

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: MarkVNomad

Date Posted: October-17-2021 at 3:10am

|

Ken, thank you for the encouragement, it really worked for me, in light of your insight here I am now a part of a select group of people who have experienced being lucky. My rudder as well as the drive shaft showed some movement and so after reading this post I felt encouraged to embark on this journey... Removed the rudder yesterday (no grease zerk), not too much difficulty, apart from the fact that the rudder couldn't drop as it didn't clear the trailer...after I had rigged an engine hoist to lift the boat at the aft lift ring, it was able to come out and then started on the coupler, here is where I am truly lucky seeing as my Sport has the interference fit style, I now have mastered the art of stripping the threads on my bolts and can also boast that I was able to stretch them, all 4 of them,... to no avail, I even was able to do a real number on the 2 nuts I had inserted instead of a socket, as that would have required me to get longer bolts with fine thread, needless to say that I made the trip to Home Depot and acquired various lengths of 3/8 bolts with fine threads, now that I was able to insert a hardened socket I was really getting some where, there were some really loud snapping noises a few times and finally I experienced true joy as I was able to see true movement of the coupler along the shaft, the bolts had to be changed several time as they would start to interfere with the bolts on the tranny..I am now the proud owner of a drive shaft with coupler moved at least 1.5" , I will move the remaining 1/2 " tomorrow once I change to another socket once again....as I was going through this life changing experience I remembered your encouraging words many times, and actually all humor aside, I really did, but I really started feeling slightly depressed anticipating the future assembly process of the coupler....will this involve a torch for the coupler and a freezer for the shaft, I have not even really been worrying about how to remove the prop... |

TG3 wrote:

TG3 wrote: