Fuel fittings

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Engine Repair

Forum Discription: Engine problems and solutions

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=50213

Printed Date: November-22-2024 at 11:11pm

Topic: Fuel fittings

Posted By: 91nautique

Subject: Fuel fittings

Date Posted: September-11-2021 at 6:44am

|

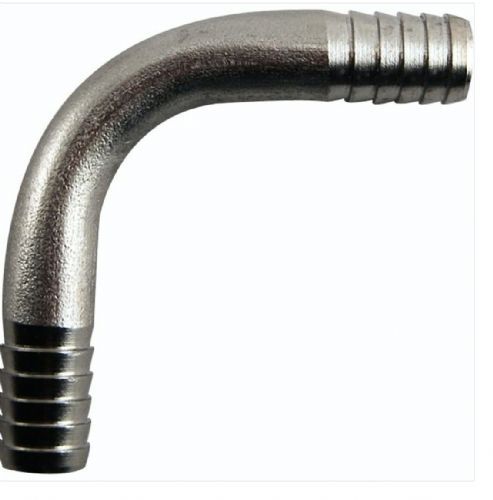

Hi all,not CC related however I’m hoping someone here may be able to point me in the right direction. I have a diesel powered boat, the fuel supply lines have collapsed where they come through a bulkhead, restricting fuel flow. I’m searching for 1/2’ 90 degree full flow elbow connectors, at 1/2 inch ID I’m right on the minimum ID required for the fuel lines given the run length,other connections and filters. The engine’s fuel delivery and return specs have to be met or exceeded, they're isn't enough room to get larger fuel line or fittings in the space I’m working with. I cant use multiple threaded fittings to make up the 90’ and can’t use a sharp 90’ as it will restrict flow,and wont reach through the bulkhead. Pictured is what I need however this fitting reduces in size (ID) on the bend. Thanks

|

Replies:

Posted By: 8122pbrainard

Date Posted: September-11-2021 at 7:44am

|

The bending may reduce the size in one direction but typically will increase the size in the other. So, the inside area is the same. With a long sweep like you pictured, there's great flow making a 90.

------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 91nautique

Date Posted: September-11-2021 at 8:25am

|

Pete -thanks for the response. I hear you,however when contacting various suppliers of the above fitting none can give me any tech info on it. All they can say is its 1/2’ and made in China, I cant even get drawings for its physical size or info on what material its made from. I’m concerned about the quality of the fitting, and failing like most Chinese junk . |

Posted By: GottaSki

Date Posted: September-11-2021 at 8:33am

|

Have you considered bending some hard line yourself? ------------- "There is nothing, absolutely nothing, half so much worthwhile as messing around with boats...simply messing." River Rat to Mole |

Posted By: 91nautique

Date Posted: September-11-2021 at 8:48am

I have but don't have the equipment, I've also looked around for companies that do it - what Ive seen is the largest size they will go to in stainless is way to small. |

Posted By: 8122pbrainard

Date Posted: September-11-2021 at 8:52am

How about a long sweep copper 90 with sweat barbed fitting on each end?  ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 91nautique

Date Posted: September-11-2021 at 9:46am

Great idea Pete however

The sweep isn't long enough to pass through the bulkhead leaving enough material to get the hose on the barb. There isn't enough barb area to double clamp. Sweat fittings could be troublesome (especially on the vacuum side) All lines run through one hole in the bulkhead,removal of existing and refitting new will be done completely by feel,there is no visible access and its tight! I’m not even sure it can be done… I need six fittings altogether 6 x 1/2’ - (two engines supply and return) and 2 x 3/8 (generator supply and return) Appreciate the input. |

Posted By: Jonny Quest

Date Posted: September-11-2021 at 10:36am

|

I would consider AN fittings that are designed for through bulkhead applications. AN fittings are designed to handle various fuels and there are a zillion different sizes, adapters, configurations, hoses etc. AN stuff costs a bit more, but I've had great success in several different applications (including fuel delivery). Here are a couple of places to look: http://www.russellperformance.com/misc/support/ https://fragolaperformancesystems.com/ JQ

------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: GottaSki

Date Posted: September-11-2021 at 11:02am

|

Reminds meI got to examine a USCG 42' buoy tender once, work of art, all marvelously bent 316 with VCR fittings ------------- "There is nothing, absolutely nothing, half so much worthwhile as messing around with boats...simply messing." River Rat to Mole |

Posted By: SNobsessed

Date Posted: September-11-2021 at 12:13pm

|

If you pack the tubing with sand & close off the ends, you can bend it without collapsing much if any. You could even make a die from wood to help make a true radius. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

Posted By: 8122pbrainard

Date Posted: September-11-2021 at 12:15pm

Chris, Has it ever worked for you? I've never had any luck using that technique. ------------- /diaries/details.asp?ID=1622" rel="nofollow - 54 Atom /diaries/details.asp?ID=2179" rel="nofollow - 77 Tique 64 X55 Dunphy Keep it original, Pete < |

Posted By: 91nautique

Date Posted: September-11-2021 at 12:25pm

|

Jonny/Gottaski I looked into AN and Swaglock fittings initially and didn't find a solution, also there is no way to get tools in there to secure everything,its going to be a struggle to get a screwdriver in one side to tighten hose clamps,on the other side of the bulkhead there is 1’ of clearance between the bulkhead and the generator soundshield (all hidden from view) It was installed new this way,all the fuel lines where run through the bulkhead and the generator pushed hard against them bending the fuel lines 90 degrees. I appreciate your input,thank you. |

Posted By: SNobsessed

Date Posted: September-11-2021 at 3:55pm

|

Pete - They did the sand-mandrel at work once. 2X3 .25 wall ROPS tubing. Pines bender. I suppose a whoie 'nother level. I have had good luck bending small tubing with a spring casing, but never worried about ovality too much. ------------- “Beer is proof that God loves us and wants us to be happy.” Ben Franklin |

GottaSki wrote:

GottaSki wrote: