engine losing power, stalling

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Engine Repair

Forum Discription: Engine problems and solutions

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=51697

Printed Date: November-21-2024 at 8:02pm

Topic: engine losing power, stalling

Posted By: MorningGlass

Subject: engine losing power, stalling

Date Posted: July-16-2024 at 3:14pm

|

I have a 96 Ski Nautique with the 351W engine. Prior to me, previous owner had already done the retrofit kits replacing the TBI with carb/mechanical fuel pump (looks like RF052019/03) ... and the kit to convert pro-tec to electronic ignition (looks like RK107025A). I bought it around 2 years ago, and while I have put a bunch of work into other things including the trailer, upholstery and fixing wiring for the heater and shower pump, it has always run really well up until a couple of weeks ago. We got a really late start on summer this year and I tried taking it out for the first time this season on July 5th. It started right up as usual, but after about 10 mins when i tried to accelerate/get up on a plane, it stalled out. I was able to restart and rev it initially in neutral but when I would get back in gear it would die at anything more than very low throttle settings. Eventually it became hard to keep it running in neutral as well. Had someone throw us a line and got it back to the launch. For winter storage, I added fuel stabilizer and filled the tank all the way up - had no issues with water in the fuel doing it this way the previous year, but to rule it out, I changed the fuel/water separator, swapped out the fuel pump, checked the fuel pickup tube and the anti-siphon valve. Fuel in the separator looked totally fine, no debris or water present. pick up tube screen was clear, anti-siphon valve was clean and working properly, tank looked clean. Put everything back together, ran it for a bit with the fake a lake and seemed good, took it to the lake, same story. Tried rolling on the throttle and it died. I'm not sure this is fuel related, but I did order a carb rebuild kit. Would be lying if I said I'm not a bit intimidated though as I have never done a carb rebuild on anything bigger than the one on my jet ski. Meanwhile, last night I pulled the coil and checked resistance. It's marked as requiring external resistor and the ballast resistor from the kit is hooked up with both wires. If I understand correctly, I'm looking for primary resistance of .5 -> 1.5 and mine came in at about 1.0. I'm not sure if that target range should be different for a coil without internal ballast. Secondary resistance is about 7900. Any ideas on where to focus attention would be appreciated, would love to find something I missed before messing with the carb. |

Replies:

Posted By: KENO

Date Posted: July-17-2024 at 6:45am

|

I'd probably focus my attention on reading and watching videos about cleaning/rebuilding a Holley carburetor, then start messing with it. Most times you'll find your problem in the primary metering block. I could say that some adjustment of the idle mixture screws would help, but if you're making adjustments from when it ran good last year, you most likely have to clean the primary metering block It sounded like it could be the accelerator pump causing the stalling on acceleration, but then you mentioned that it won't really idle at all anymore. Have you looked down the throttle bores while it's trying to idle to see if there's a bunch of gas dumping in? A bunch of gas dumping in is not what you want to see. You should see nothing because at idle it's all going in below the throttle plate. A bunch dumping in would mean your inlet needle valve is leaking by due to junk in the seat, or it's worn out. So..... some reading/watching videos will get you ready to dive into your carburetor  Here's a good video in the thread linked below. Click on the link in Wacko's first post http://www.correctcraftfan.com/forum/forum_posts.asp?TID=49871&title=video-holley-4160-carburetor-rebuild" rel="nofollow - link |

Posted By: Jonny Quest

Date Posted: July-17-2024 at 12:17pm

|

Holley made some videos called “quick flicks” that can be found on YouTube. Do a search on YouTube for “Holley quick flicks carb” and you can improve your carb knowledge with informative videos. Usually some Holley guy named Norm does the video and he is pretty good. Topics like accelerator pump, idle circuit, rebuild, etc. JQ ------------- Current 2003 Ski Nautique 206 Limited Previous 2001 Ski Nautique Open Bow 1994 Ski Nautique Open Bow Aqua skiing, ergo sum |

Posted By: MorningGlass

Date Posted: July-17-2024 at 11:27pm

|

Thanks guys, the rebuild kit came in today, with the exception of the secondary diaphragm which they will send when it comes in. I picked up a set of bits that included clutch heads for the secondary metering plate, still need to clear a space in the garage to set up for this so I don't lose parts. I should mention that I think the accelerator pump is working -- when I roll on the throttle it does initially accelerate. It just kind of peters out and dies after the RPMs start to climb. And it only seemed to happen out on the lake when I put it in gear. Running it both at idle and revving it with the fake-a-lake in the driveway it seemed to idle and rev just fine, although perhaps a bit lower than expected RPMs, Will try idling it and see if I can spot any fuel dumping in, about the only thing I confirmed on the lake was that the accelerator pump was squirting some fuel in when I pumped the throttle before starting it. |

Posted By: MorningGlass

Date Posted: July-18-2024 at 1:12am

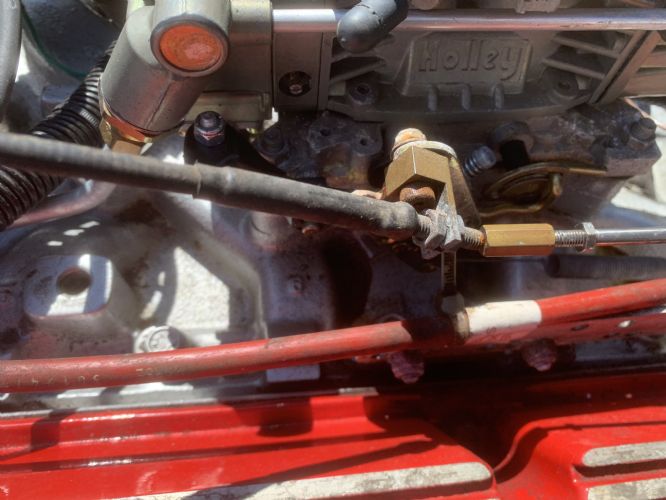

OK, so was looking at the throttle linkage and am wondering if this is the problem. There is a perfect pass installed, and from what I can tell, the black cable to the left goes to the solenoid for that system that controls the throttle when it's engaged, while the silver rod connects with the longer brass nut to the end of that cable and both work the throttle lever. The first thing that caught my attention was the angle to the forward (left) side of the long brass nut, seemed like it might be wrong, but it's not threaded onto the left side, just onto the end of the throttle silver rod. The locking nut was all the way backed off. After looking at this the other thing I noticed is that when I set full throttle and look down past the choke plate, it appears the throttle plates are just barely cracked open, would expect them to be wide open wouldn't they? if I understand correctly, the rear throttle plates would only get sucked open by that vacuum secondary diaphragm, but what would prevent the primary throttle blades from opening? does the choke limit their travel? |

Posted By: MrMcD

Date Posted: July-18-2024 at 2:39am

| If you have the throttle wide open and you are holding your choke wide open you should see the lower butterfly's in the front 2 barrels wide open. If not your throttle cable is not hooked up where it can function or it has broken. |

Posted By: KENO

Date Posted: July-18-2024 at 8:03am

Nice little tidbit of info to throw out there about Perfect Pass being installed  From your picture it looks sorta, maybe about right except for the locking nut being backed off but if you look at the link below you'll find a few videos from Perfect Pass about things like PP linkage test, Installing the brass L adapter Servo motor auto tighten test Adjusting for a high idle on a new install ..................and a variety of other videos. http://perfectpass.com/support" rel="nofollow - link This should at least help you figure out if it's right and adjust it if necessary |

Posted By: MorningGlass

Date Posted: July-20-2024 at 9:47pm

|

Alright, I got the carb rebuilt last night and re-installed it today. Engine runs again great in the driveway, but seems like it's done that before, so will see tomorrow afternoon how it does in the water. I noticed something else that seems screwy, never noticed it before. There is some kind of vacuum port that comes out of the lower left side of the choke -- has a threaded brass fitting on there that looks like it's supposed to hold on a tube, but no tube anywhere to hook up to it. I confirmed today when the engine was running that I can feel air getting sucked in through it but I'm not sure what it's for. It's the brass-colored fitting threaded on to the lower left side of the choke, and forward of the vacuum secondary diaphragm rod. Should this be connected to something? Capped off? Anyone know what it is? Thanks!  |

Posted By: GottaSki

Date Posted: July-22-2024 at 9:55am

|

Leave it, else you will burn out your electric choke ------------- "There is nothing, absolutely nothing, half so much worthwhile as messing around with boats...simply messing." River Rat to Mole |

Posted By: Roy87SN

Date Posted: July-22-2024 at 10:46am

|

I have the exact same thing on my carburetor, and like you thought, it had to be connected to something…but NO, nothing connects to that fitting, it’s just there. It’s a brand new Holley from skidim, and that’s how it came right out of the box. Regards Roy 1987 Ski Nautique 2001

|

Posted By: MorningGlass

Date Posted: July-22-2024 at 12:01pm

|

Yeah, I took it off and found two washers with a piece of screen between them, came to the conclusion that whatever it was for was by design. However real news is that I got it out on the lake yesterday after getting the freshly rebuilt carb re-installed and it runs great! I've had mixed results with rebuilding carbs in the past and had never done a 4 barrel one like this, but really wasn't any more complicated, just a bit more components to go through. I also lucked out a bit during re-assembly. I found my temporarily missing needle valve for the accelerator nozzle in my driveway. I thought for sure I was going to need to order a replacement. Thanks to everyone here, really appreciate the help! |

Posted By: KENO

Date Posted: July-22-2024 at 8:57pm

|

If you didn't have that small controlled vacuum leak flowing air into the engine, it would be like being locked in a car with the windows closed on a 100 degree day. You wouldn't last long and like mentioned earlier, neither would the electric choke assembly

|