Raw water pump rebuild

Printed From: CorrectCraftFan.com

Category: Repairs and Maintenance

Forum Name: Engine Repair

Forum Discription: Engine problems and solutions

URL: http://www.CorrectCraftFan.com/forum/forum_posts.asp?TID=51733

Printed Date: November-21-2024 at 11:37am

Topic: Raw water pump rebuild

Posted By: malcolm2

Subject: Raw water pump rebuild

Date Posted: August-16-2024 at 5:28pm

|

i will admit, i suck at searching on a forum. So the answer might be out there. I see tons of Youtube vids where people are CHANGING the impeller. could do that blindfolded. There are other vids for other styles of pump. This is on my 92 SN PCM351. Sherwood belt driven pump. Is the engine a G21 or the pump? vendor gave me that #, it is all over the net, so I found stuff i need. Pulled the pump, the pulley is not spinning freely enough for me. so much stuff in there. shaft, 2 bearings, seal, some spring thing, bunch of cir-clips, 3 o-rings, on and on. kits available at various prices and various part counts. Need to know what goes where, how to take it apart would be good too. I got the seal and 1/2 the springy thing out. The act of doing that has freed up the shaft and pulley spins better. spring thing had a very worn seal. So, long question summarized: please supply a link with a video of complete guts removal of the RWP. Worse case an exploded view dwg, maybe. or even written instructions.  Thanks, Clark  |

Replies:

Posted By: KENO

Date Posted: August-16-2024 at 7:53pm

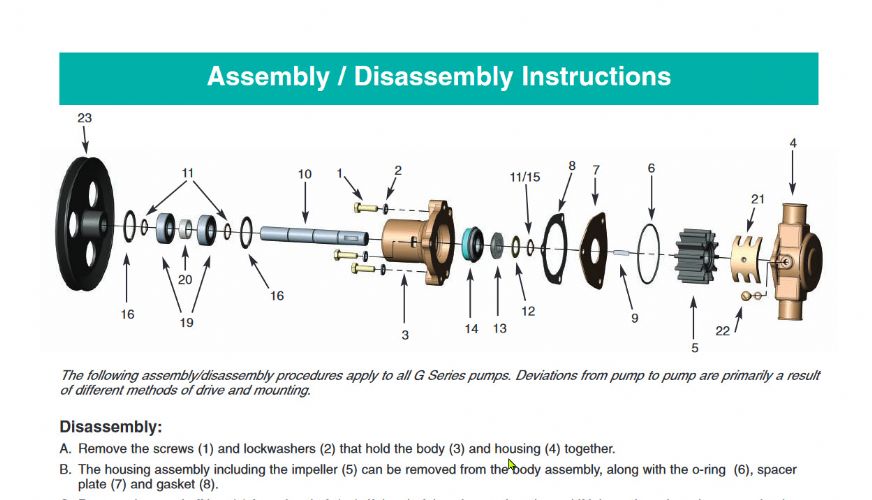

Well here's your worse case...............some Sherwood instructions in the link  http://flutech-marine.com/mediafiles/Sonstiges/PDF/Sherwood/Sherwood%209959-technical-guide.pdf" rel="nofollow - link And here's an old thread that was better at one time before the "picture monster" made a bunch of pictures disappear http://www.correctcraftfan.com/forum/forum_posts.asp?TID=46865&title=sherwood-pump-help" rel="nofollow - link Make sure you look at the links that are in the CCF thread in the link too. Sherwood says to press the pulley off, others have left the pulley on and pressed the shaft out in the other direction. You'll see that in the reading above. A hydraulic press is real handy and making sure you get the appropriate snap rings out at the right point will help to make sure you don't break the bearing housing

|

Posted By: malcolm2

Date Posted: August-16-2024 at 9:25pm

|

That is great. thanks. It is most unfortunate that all those pictures are gone. Sucks even worse with all the comments about how great the pictures are to have. What happened?  |

Posted By: malcolm2

Date Posted: August-20-2024 at 11:27am

|

for future readers here...... Sorry no pictures of my work. from 8 to 4 easy to remove. just 3 bolts. 14 to 11/15 also easy if you have some cir-clip pliers. I say easy, but this is where the problems start. 14 is an assembly and the spring and the seal came right out. Seal was damaged. Everything looks old and brittle. So i bought the SMALL kit that included everything so far. My snip in the OP is the LARGE KIT. I did not buy that. Small kit = 14 - 6 (not including the key). Key is #9 here, but called 18 in the manual. this dwg and the manual don't perfectly align as the manual goes thru the parts. The bottom of 14, the green part is wedged into the housing. I had to uses some screws and drill into the "cup", then pry it out. Of course the act of drilling, screwing, pulling, pulling the screw out, etc..... damaged a bearing. So now I need 2 bearings. Also probably original 35 years old and about 1500 hours. Maybe not, but I sure have never been in here. Anyway, new bearings alone look to be about $25 each. DAMN. Very tuff to get my circ-clip tool in the housing to the bearing. about 1.5" down in there on the middle groove of the shaft. I have one of those circ-clip tools from Lowes that has removable tips of varying point sizes and tip angles. SO lots of choices. I had to use the straight tip not being attached to the plier part. I got them both. 16 and 11 are out. Now for the fun... DID NOT REMOVE THE PULLEY>>>> again, i used the Lowes circ-clip tips between the housing and pulley and was able to get the other 16 and 11 out. I was pretty proud of myself at this point  Found a 18" scrap of 2x4 and wacked the shaft a few times and the shaft and 2 bearings came out. ALL dis assembled now. YEE-HAW. Now i wait for the bearings to arrive.

|