Pier & Dock Building or Buying Ideas Wanted |

Post Reply

|

Page 12> |

| Author | ||

JoeinNY

Grand Poobah

Joined: October-19-2005 Location: United States Status: Offline Points: 5698 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Pier & Dock Building or Buying Ideas Wanted Topic: Pier & Dock Building or Buying Ideas WantedPosted: July-22-2014 at 11:08pm |

|

Agreed - looks good kid! |

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: July-20-2014 at 6:45am Posted: July-20-2014 at 6:45am |

|

|

Nice job Chris. It sure looks great.

|

||

|

||

PLBC

Gold Member

Joined: January-25-2006 Location: United States Status: Offline Points: 568 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: July-20-2014 at 1:17am Posted: July-20-2014 at 1:17am |

|

|

Looks good, any feet on the posts?

|

||

|

||

Hollywood

Moderator Group

Joined: February-04-2004 Location: Twin Lakes, WI Status: Offline Points: 13520 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: July-18-2014 at 3:49pm Posted: July-18-2014 at 3:49pm |

|

|

Wondering if the sections will sag in the middle.

|

||

|

||

IAughtNaut

Grand Poobah

Joined: August-22-2010 Location: TN Status: Offline Points: 2568 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: July-18-2014 at 3:18pm Posted: July-18-2014 at 3:18pm |

|

|

Looks great Chris, and tell your brother I've always been a fan of his music. Man out of time is probably my favorite, but Alison is great too.

|

||

|

||

quinner

Grand Poobah

Joined: October-12-2005 Location: Unknown Status: Offline Points: 5828 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: July-18-2014 at 3:04pm Posted: July-18-2014 at 3:04pm |

|

|

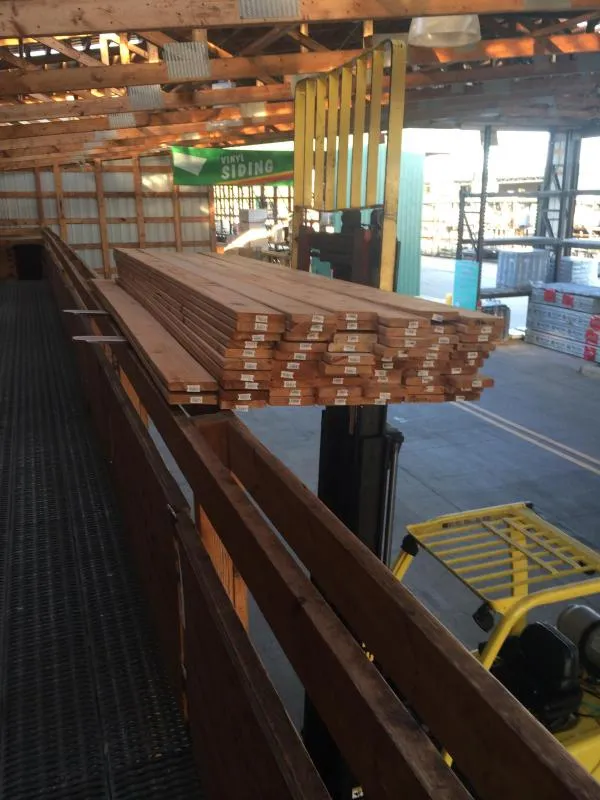

Better late then never, pics as promised:

Took a while to find decent stock at Menards  A little help from My Brother   The stack started to build   Once the boxes were complete moved on to mounting all the hardware. As Joel mentioned the D&H components were great and included everything, the only issue I had was the carriage bolts supplied were about 1" short on the end boards where I had 2x4 ledger board along the 2x6, worked fine everywhere else.  Then it was time to cut the leg posts, purchased (5) 21' sticks of 1.25" ID schedule 40 galvanized pipe from Fergusons (thanks Bret Hectus for the great pricing) and my plumber buddy helped me cut them all down with his 300 machine. Including cutting the threads off each end had about 30 cuts to make.  Then it was just a matter of putting them in, definitely a 2 man job to carry, heavy but not a backbreaker. Really happy how everything turned out, very sturdy and nice to walk on with the deck boards running along each section instead of across them. The only thing I would have considered doing different is tightening up the gap between the deck boards, 1/2" is ok but 1/8" or 1/4" may have been better. Added some budget solar lights at most posts, looks great at night but people have a tendency to grab them and of course the plastic fixtures break pretty easily.

|

||

|

||

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 11:41pm Posted: June-27-2014 at 11:41pm |

|

|

I had some minor problems this year with my lift. When it was built 16

years ago it was primarily for the Shamrock. The cross pipes for the lifting cables needed to be 13 feet across so they took a 10 and welded 3 more feet on. I hang this new boat on and ended up snapping the bad weld which happened to be right in the cable lift area. I was changing the steering cable when it happened. No one was hurt except the boat.I then had to finish installing the cable so I could drive the boat to the ramp to get it out.In my haste because of approaching darkness I put the helm together wrong so it steered backwards! Had a hard time finding 21ft pipe so that I could cut it down instead of welding it but finally did. Then got to thinking I don't like the butt welds the same guy did on the bearing supports so I cut some angle and had a welder come out and redo those too. In the meantime I'm trying to get the guy who's repairing Quinners gel to just look at mine,he says fine bring it over but call first,I call twice and get his help who proceed to tell me their too busy. Decided to do it myself with Spectrum, they tell me they get the color right from the company who supplies Correct Craft so we will see how it turns out,I can always take it in.I'm in the process now of building a step so we can get in the boat easier when it's on the lift and I'll be done.

|

||

|

||

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 10:50pm Posted: June-27-2014 at 10:50pm |

|

|

We sit and complain about Illinois but there does not seem to be many restrictions

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 8:34pm Posted: June-27-2014 at 8:34pm |

|

Bruce, Wisconsin is the same way. I only have a 8'by 16' "L" section at the end of my dock and it's over the allowed sq. ft.!! You have to jump through lots of hoops to install a permanent piling pier!! |

||

|

||

NCH20SKIER

Grand Poobah

Joined: December-16-2004 Location: United States Status: Offline Points: 2214 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 8:16pm Posted: June-27-2014 at 8:16pm |

|

|

Thanks Bruce-

Well the restrictions are different the quirkiness is much the same. It kind of depends on who is the Lake Steward (Duke Power - Alcoa etc, each have thier own regulations (many of which make little sense). Here (Badin Lake - Alcoa) you can no longer attach to the "river bottom" more than ~10' from shore - everything has to float - I did not qualify as a grandfathered lot. Also, almost all the lots on the lake you can not cut trees within 10' above full pond elevation. Here I lucked out and can clear to the waters edge. |

||

|

'05 206 Limited

'88 BFN |

||

|

||

Riley

Grand Poobah

Joined: January-19-2004 Location: Portland, ME Status: Offline Points: 7961 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 10:22am Posted: June-27-2014 at 10:22am |

|

|

Beautiful dock, Greg. I find it interesting how in Maine, the state won't let you make any improvements within 100' of the lake, other than temporary docks, but in NC you can build nice boat houses and docks like yours and at White Lake.

|

||

|

||

NCH20SKIER

Grand Poobah

Joined: December-16-2004 Location: United States Status: Offline Points: 2214 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 8:21am Posted: June-27-2014 at 8:21am |

|

|

Joe,

Invite is open. Might try to put together something in October at the Lake but don't let that stop a visit anytime. Like that sandy bottom in your pic's |

||

|

'05 206 Limited

'88 BFN |

||

|

||

JoeinNY

Grand Poobah

Joined: October-19-2005 Location: United States Status: Offline Points: 5698 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-27-2014 at 12:32am Posted: June-27-2014 at 12:32am |

|

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-26-2014 at 8:41pm Posted: June-26-2014 at 8:41pm |

|

Me too!!

|

||

|

||

storm34

Grand Poobah

Joined: November-03-2008 Location: Dexter Iowa Status: Offline Points: 4493 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-26-2014 at 2:40pm Posted: June-26-2014 at 2:40pm |

|

Still holding my breath for these. |

||

|

||

NCH20SKIER

Grand Poobah

Joined: December-16-2004 Location: United States Status: Offline Points: 2214 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-24-2014 at 7:53pm Posted: June-24-2014 at 7:53pm |

|

|

'05 206 Limited

'88 BFN |

||

|

||

MustangMadness

Senior Member

Joined: April-15-2014 Location: Seacoast NH Status: Offline Points: 114 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-24-2014 at 6:53pm Posted: June-24-2014 at 6:53pm |

|

|

What an advantage you guys who live in non

climates have when it come to docks. climates have when it come to docks.

|

||

|

I like a 6' beam on a small lake... My Muscleboat

1975 Mustang 225 307RH |

||

|

||

quinner

Grand Poobah

Joined: October-12-2005 Location: Unknown Status: Offline Points: 5828 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-23-2014 at 11:40am Posted: June-23-2014 at 11:40am |

|

|

Wrapped up the Dock Project this weekend, pics coming soon

|

||

|

||

75 Tique

Grand Poobah

Joined: August-12-2004 Location: Seven Lakes, NC Status: Offline Points: 6130 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-23-2014 at 11:33am Posted: June-23-2014 at 11:33am |

|

|

Speaking of docks, I did a minor upgrade this weekend. New top.

I could have sworn I just did this a year ago....Oh yeah, that's because I just did do this a year ago. Had I known I would be moving within the year, I probably wouldnt have gone through the fuss.  Last year's project included lowering the dock about 18 inches, which I didnt have to do on this one. It's a little higher than I like but not worth the effort of lowering. This was phase one of the project. Phase two, going out another 5 to 10 feet will occur as soon as I get permit in place and materials. |

||

|

_____________

“So, how was your weekend?” “Well, let me see…sun burn, stiff neck, screwed up back, assorted aches and pains….yup, my weekend was great, thanks for asking.” |

||

|

||

M3Fan

Grand Poobah

Joined: October-22-2005 Location: United States Status: Offline Points: 3185 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-09-2014 at 7:05pm Posted: June-09-2014 at 7:05pm |

|

I used rigid galvanized electrical conduit. Very stout and IIRC 10.00 per stick at 10ft from Menards, price seems to have doubled since 2010 I guess, or maybe it was on sale at the time. http://www.menards.com/main/electrical/rough-electrical/conduit/1-1-4-x10-rigid-conduit/p-1470046-c-6423.htm |

||

|

2000 SN GT40 w/99 Graphics/Gel

2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

||

|

||

IAughtNaut

Grand Poobah

Joined: August-22-2010 Location: TN Status: Offline Points: 2568 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-09-2014 at 6:59pm Posted: June-09-2014 at 6:59pm |

|

You should have a couple cases already laying around, right? Hello cost synergy.

|

||

|

||

quinner

Grand Poobah

Joined: October-12-2005 Location: Unknown Status: Offline Points: 5828 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-09-2014 at 6:23pm Posted: June-09-2014 at 6:23pm |

|

|

Progress report, framed up the 10 sections this weekend, the dock hardware should be here this week and which/where I get the posts is TBD.

In an effort to trim some lbs built the first one using 2x6 decking boards in lieu of 2x6 dimensional, which are 1/4" thinner and also have the nice rolled edges like the 5/4 decking. We tested with 3 of us standing and walking on a completed spanned section and it felt fine so all the rest were built the same way. Not sure the exact finished weight but I can carry 1 by myself and with 1 guy on each end it's quite reasonable. Hardware is coming from DH Docks, using corner clips throughout which are about 5x5 each face and should add a bit more rigidity once all bolted up. Sections all look great, running the deck boards the long way feel great to walk on but will make it important the docks go in as a nice straight line. Now that summer break has begun, going to try and get my daughter to lightly sand and stain the cedar deck boards this week, anybody have a suggestion on a translucent exterior stain?? |

||

|

||

ny_nautique

Platinum Member

Joined: June-01-2011 Location: Albany NY Status: Offline Points: 1215 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2014 at 9:43am Posted: June-07-2014 at 9:43am |

|

|

I had posted earlier last month about building a floating dock. We ended up using our old aluminum poles and having some more welded, but I believe they were 1.75". We did 2 for every 8' length. I also bought some Taylor Made P-channel dock bumper that we're installing this weekend.

If you need that P-channel, Jamestown Distributors gave me the best deal with shipping. Shipping at the other places kills the better deals. And, Jamestown will price match.

|

||

|

- Jeff

1999 Ski Nautique |

||

|

||

JoeinNY

Grand Poobah

Joined: October-19-2005 Location: United States Status: Offline Points: 5698 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2014 at 1:33am Posted: June-07-2014 at 1:33am |

|

|

I used the 1.25 pipe and depending on the depth they are ok... if they get longer than 6 ft you might be more wobbly than usual. I paid 223$ with tax for 7 10 footers at the local HEP. So in the same ball park - 3.50 a foot cut to your desired length with no scrap would be ok by me, will be closer to 5 after I cut off the scrap. 200lbs is heavy. I would consider making the deck removeable. I just have to build another 30 ft of removable decking tomorrow and I will have built or refurbished and installed 23 sections of dock this year. It's not that much fun building them after 4 or 5. I am ready to lie down on one and sleep a couple days.

|

||

|

||

OverMyHead

Grand Poobah

Joined: March-14-2008 Location: MN Status: Offline Points: 4861 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-07-2014 at 12:57am Posted: June-07-2014 at 12:57am |

|

My neighbor had 48 feet of steel roll in. He would chain it to the plow mount on his old pickup, raise the "plow" and drive it in or out. It maybe took took all of 2 minutes. He had a modified come-along that slid into the top of the dock post and hooked to the dock frame below to set the leg height. He never got wet. |

||

|

For thousands of years men have felt the irresistible urge to go to sea, and many of them died. Things got better after they invented boats.

1987 Ski Nautique |

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-06-2014 at 9:53pm Posted: June-06-2014 at 9:53pm |

|

|

Chris,

One thing that bothers me is the weight of 200. Remember we are not getting any younger plus, HW may not be around to help you when needed.  I can't lift much now like I used to! I can't lift much now like I used to!I agree with Gary about the 1&1/4 pipe. I see in your material list they are for the 1&1/4 but that's not much. Link these extrusions you are using. I,m familiar with the galv dock parts but not the extrusions. |

||

|

||

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-06-2014 at 8:58pm Posted: June-06-2014 at 8:58pm |

|

|

Will 1 1/4 pipe hold up? What length do you need? I just bought 21 foot 1 1/2 black pipe at Menards,they were 55 ea.

|

||

|

||

JoeinNY

Grand Poobah

Joined: October-19-2005 Location: United States Status: Offline Points: 5698 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-06-2014 at 8:14pm Posted: June-06-2014 at 8:14pm |

|

|

Flat brackets instead of corners?

|

||

|

||

quinner

Grand Poobah

Joined: October-12-2005 Location: Unknown Status: Offline Points: 5828 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: June-06-2014 at 12:38pm Posted: June-06-2014 at 12:38pm |

|

|

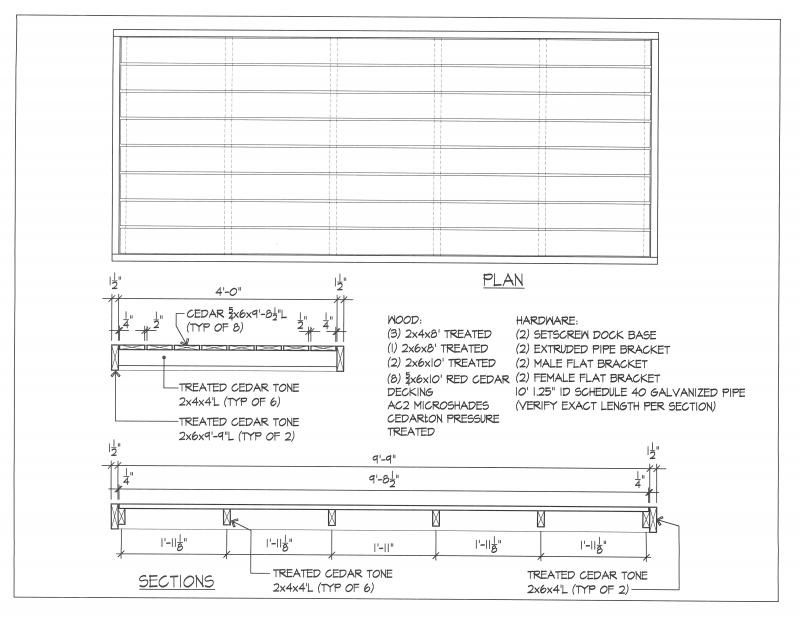

Joel, thank you for the outstanding lead to DH, using their hardware, one question though, where did you get the 1.25" ID Schedule 40 Galv Pipe? DH wants $3.75 per ft, menards has "dock pipe" for about $2.00 per ft but it looks to be a lighter gauge.

So here is the plan & sections for a typical 4x10 section, Treated frame with Cedar decking, wanted a flush walking surface and the decking running in the direction of travel.  They are going to be a little heavy, close to 200lbs each but that's OK as I only need to handle them twice a year. Lumber per section is about $90, dock hardware about $102 and the pipe about another $30. Going out 80' and will have (2) sections off to one side to create a 12' X 10' deck at the end. What do you all think?? |

||

|

||

john b

Grand Poobah

Joined: July-06-2011 Location: lake Sweeny Status: Offline Points: 3241 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-27-2014 at 5:39am Posted: January-27-2014 at 5:39am |

|

|

Free beer and maybe a pull for this old gimpy guy with some pointers? Thats all it takes here, as long as I have some advance warning.

I have an aluminum Shore Station dock that I like pretty well. It is fairly light and comes apart and adjusts easily, however they are a bit pricy if you need the type of length you are talking about. I think there are other brands that are easier to adjust on the market now. I built a deck the summer before last and added a guest dock last fall so my guests can tie up and enjoy a refreshment when they visit. (Matt, Peter, don't forget to stop). They lower the water 3-1/2 feet or so for the winter so I waited until then. I had to shovel it two mornings to finish. A treated dock ids cheap at about $15 / ' in materials to construct. It is heavy and doesn't come apart easily though. Whatever you decide LMK if you want a hand. Shore Station dock, a bit pricy but really easy. This one is ten years old. This little 20" wood dock ( not stained yet) cost me just under $300 in materials but I had the pipe so I didn't price that in. You could just as easily use treated 4X4 for the posts. 2-2X8 joists with 5/4 inset on 2X4s sistered to the inside of the joists. I inset the legs to eliminate external hardware that could leave a mark and put mooring lines through the deck knotted for retention. 2'9" wide including the joists to get the most out of the 8' 5/4s. It looks odd with the water down. I had to make two trips to the lumber yard with my trailer. I figured the weight of dry treated. It was double that weight. the legs are vertical, the appearance that they are not vertical is an illusion.  Here is what it looks like with the water up. It is very secure and has a nice surface to walk on. This is before I built the deck. |

||

|

1970 Mustang "Theseus' paradox"

If everyone else is doing it, you're too late! |

||

|

||

Post Reply

|

Page 12> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |