Another BFN Rebuild |

Post Reply

|

Page <1 34567 31> |

| Author | |

BuffaloBFN

Grand Poobah

Joined: June-24-2007 Location: Gainesville,GA Status: Offline Points: 6094 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 9:28am Posted: January-15-2010 at 9:28am |

And microballoons don't weigh much! Tim M, do yall use cabosil? What do you think of my theory above? |

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 10:46am Posted: January-15-2010 at 10:46am |

|

BFN

If it works for you cool, we use a bunch of different mix ratios new ones all the time. Tim How much mil fiber do ya need? I can send you "some". If you look at it under magnafication.,the mil fiber tears out when it fails (adds strenght)and cabosil just shears off in the resin. Same with any "sphears" round shape filler. |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 10:59am Posted: January-15-2010 at 10:59am |

I agree on the fiber shearing VS: just shearing off at the bond. Any fiber type filler will act similar to a glass fabric and it really the fiber that's gives the strength so it's a higher strength. My concern and comment is just don't use something real weak meant for easy sanding like a wood flour under the glass. Go with one of the less expensive higher strength fillers. |

|

|

|

Morfoot

Grand Poobah

Joined: February-06-2004 Location: South Lanier Status: Offline Points: 5320 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 11:43am Posted: January-15-2010 at 11:43am |

|

Greg, Yes we do use cab-o-sil here at work but I personally have not used it. We have some here in our shop but I don't think its even used in engine apps. It may be here for personnal projects. I can remember from a 2 week composite class that cabosil is used to thicken your resin. It does strengthen the resin but not sure how much. I leave that up to the engineers.

The primary recipe we use for fillers is a mixture of microballons. Replacing sections of damaged honeycomb core in airframe panels is to remove the damged skin and core and replace it with the same using an adhesive but filling in voids and gaps with microballon recipe. Delta provided us with a training use only handbook on composites but its at the house. I'll have to dig into this weekend and report back the cliffs note version of (microballons,cab-o-sil, and milled fibers) As far as your theorys go..... I'd buy them. I sure CC didn't put too much thought into it when they built our boats but I have been known to be wrong.

|

|

|

"Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman"

|

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 1:50pm Posted: January-15-2010 at 1:50pm |

|

Greg, Mike- we’re making enough changes to the structure of the boat that it makes sense to lay it out first to get an idea how all the new pieces will fit together. Like I told Alan, there are enough inconsistencies in the hull that we’ll be spending a lot of time with a tape measure and cardboard to build everything!

Tim, thanks for the info! Interesting stuff here... Andy, Joe- thanks for the offer on the milled fiber! To answer the question, I have NO IDEA how much I would need. With all the bedding and fillets on the boat, probably a lot! From what Greg is saying, it sounds like its quite a bit denser than cabosil- does that mean it would go farther (based on volume)? I suspect not... A mixture of those 2 plus talc might be just the ticket- thanks for the idea Greg! Do you think a 50 lb bag of milled fiber, 10 lbs of cabosil, and 50 lbs of talc would be somewhere close to the right amount? What kind of ratio did you use (by volume)... somewhere around 2:2:1? Ill probably pick up 4 gallons of glass bubbles for final fairing. |

|

|

|

BuffaloBFN

Grand Poobah

Joined: June-24-2007 Location: Gainesville,GA Status: Offline Points: 6094 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 4:01pm Posted: January-15-2010 at 4:01pm |

|

Tim, I ordered everything in the 2.5 qt size and had to re-order cabosil, mil fiber, and talc. I re-ordered in the same size and used about half of each.

|

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 4:33pm Posted: January-15-2010 at 4:33pm |

Hmmm... does that mean you used a ratio closer to 1:1:1? Id wager a guess that I'll use about twice the amount of fillers as you did since I have about twice the number of ribs and bulkheads... that gives me an idea of what I need. Thanks! |

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 6:41pm Posted: January-15-2010 at 6:41pm |

|

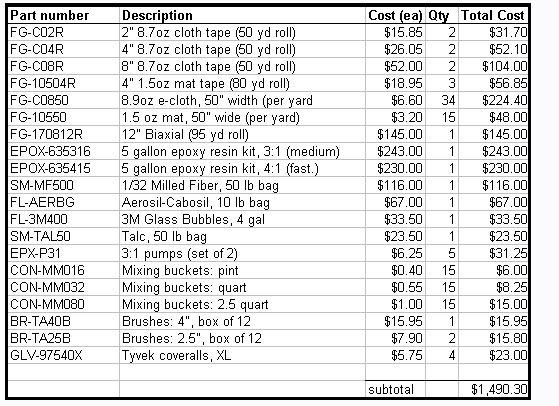

OK, here's a rough cut at the fiberglass materials list. I didnt put a lot of thought into how much tape we'd need- I just doubled what we bought for Nick's Skier. Everything else should be relatively close. I know the fillers are overkill, but theres a big jump in sizes, so I went for the volume discount in hopes of not running out. Overruns can always be used on later projects! 10 gallons of resin may be cutting it close, but Ive got an extra stash in the basement that I can tap into if we run out. I split the 10 gallons between the 3:1 medium and 4:1 fast. I'm waiting to hear back from Joe with what type of glass he used to laminate his main stringers, and will adjust the order accordingly once I get his input.

|

|

|

|

WakeSlayer

Grand Poobah

Joined: March-15-2006 Location: United States Status: Offline Points: 2138 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-15-2010 at 6:52pm Posted: January-15-2010 at 6:52pm |

|

I think you are going to need WAY more brushes than that.

|

|

|

Mike N

1968 Mustang |

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 1:01am Posted: January-16-2010 at 1:01am |

|

So whats the reason for using talc? A stringer job is a high performace application. Talc is one of the main constituants of bondo.

|

|

|

|

81nautique

Grand Poobah

Joined: September-03-2005 Location: Big Rock, Il Status: Offline Points: 5781 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 10:40am Posted: January-16-2010 at 10:40am |

|

Man that resin in the 5 gallon kits is the way to buy it. Actually makes it look cheap.

Tim, If you have a harbor freight store around check them out for your disposable supplies, I bought a 36 pack of 2" brushes for $9.99. They have larger sizes as well. Won't save you much in the grand scheme of things but it helps. |

|

|

You can’t change the wind but you can adjust your sails

|

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 11:42am Posted: January-16-2010 at 11:42am |

|

you forgot dishwashing gloves Mage, and i do like a list minus foam.

The talc works very nicely to thicken up the resin and the two gel well together, some may say it weakens the resin....these arnt space shuttles. Can we also get an estimate of beers required to complete the job properly |

|

|

"the things you own will start to own you"

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 11:45am Posted: January-16-2010 at 11:45am |

Greg mentioned way back in the thread that it smooths out the consistency but I too would question it blended in on a high strength application. I've never used it and have always relied on West #410 Microlight for fairing. I bought a large container way back and it's lasted for many projects! Yes the 5 gal. epoxy kits are the way too go. The pump kits come with the suction tube extensions to get to the bottom of even the large containers. |

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 4:59pm Posted: January-16-2010 at 4:59pm |

|

Alan, good call on using harbor freight for the disposables... Ill take them off my USC order.

I spoke with Joe yesterday and he gave me some feedback on the layup and bedding. Now Im thinking I wont be bedding any of the ribs alongside the stringers. I may not bed all of the forward ribs either- perhaps every other. I may also remove the mat tape from my schedules and instead use the 4" cloth tape. Joe's thought is that this will reduce the chance of introducing air bubbles between the layers (laying the thicker mat between layers of cloth). Any mat he used was put on last... and Ill be using Biax in its place as the final layer. So Andy, Pete- you vote no talc? Seems that a 1:1:1 of milled fiber, cabosil and talc would be a decent compromise on strength, smoothness, weight and cost. What would you suggest instead? Id like to choose from what US Composites has to offer. Thanks for the feedback, guys! |

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 7:46pm Posted: January-16-2010 at 7:46pm |

|

All the repairs I've done with thickened epoxy, milfiber & cabosil no talc, microbeads or microballons. Thou we do use a couple of epoxy adhesives that have glass beads already in the mix .05% for bond line control.

Your going above and beyond with cosa and epoxy using the best materials available, I think it's a no-brainer to use the strongest fillet materials also. I would use 100% milfiber in the first layer or two of glass tape for the main stringers / hull fillet. |

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-16-2010 at 8:03pm Posted: January-16-2010 at 8:03pm |

Andy, I was following you right up until this statement... can you please explain what you mean? |

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 1:24am Posted: January-17-2010 at 1:24am |

|

Tim,

When you lay the first layer or two of glass tape in the fillet (main stringer to hull)prep the surface by lightly sanding with 220 grit to give it the proper tooth (both layers) Use a little milfiber in the resin but be sure it still has good wet out. Shape a couple of old paint brush handles to fit the radius. Lay the first layer of tape and roll it in. Use the shaped paint brush handle to debulk it (force it down into the radius) Repeat on the second layer of tape. It will nest the plys of material, force it into the radius and give it qusi-isotropic strenght to defeat the harmonic vibrations in the hull (more resistant to harmonic delamination failure over the life of the part) Aircraft quility baby... Eric's right thou it's a boat, the extra detail costs nothing but time. |

|

|

|

Nautique2001

Grand Poobah

Joined: June-14-2004 Location: Massachusetts Status: Offline Points: 2832 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 1:46am Posted: January-17-2010 at 1:46am |

|

Wow, pretty impressive. Tim, you should be in sunny Orlando designing Nautiques. One thing though, you'd better do something about that slow and tired engine of yours.

I'm going to purchase another mirror for my boat so I can have a couple of angles of your BFN behind me. I'm going to purchase another mirror for my boat so I can have a couple of angles of your BFN behind me.

Keep the pics coming. It's pretty amazing stuff. Ken |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 1:04pm Posted: January-17-2010 at 1:04pm |

|

i have resin and talc droppings on the floor, and the only way to get it off the floor is with an air hammer, or a sledge, resins have changed in the last 25 years and CC felt back then they were strong enough but didnt factor in foam rot. your re-building these boats becasue or rot, not because of strength issues, there are places where epoxies are needed and places where polyester is very suitable. obviously bonding a stringer to the hull you would go straight epoxy. using fillers such as talc is reccomended without disregard to strength from the manufacturer. a good polyester resin is 28.00 bucks a kit. and it does have a use where epoxy is not needed. the stringers in these boats are 90% for holding the engine in or you would have seen 10000 CC's crack in half at this point. setting a prescedent is fine but also polyester is also a proven less expensive product that can be used in these boats. some guy's are on a budget and may mis-costrue that 700.00 bucks worth of epoxy is not him worth doing the boat and may opt to send it to the dump. point being, these boats can be done economically and it may be "scaring" a prospective CC rebuilder away

|

|

|

"the things you own will start to own you"

|

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 2:14pm Posted: January-17-2010 at 2:14pm |

|

Eric,

I agree, if I was doing this for a living - it's a boat. I hope I'm a good ambassador of these old boats. Trouble is "I LOVE" these old boats and I've got over 30 years repairing military aircraft. The repair techniques cross over some in composite material. I'm looking at my old division officer's survival knife hanging on my desk. In 1976 I worked at US Naval Test Pilot School and He was an instructor. Anyway he crashed and I took the knife off his broken body. It reminds me that no matter how perfect my minds eye see's it, my hands do the best they can. I deleted most of what I wrote - but you get it. |

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 2:43pm Posted: January-17-2010 at 2:43pm |

|

Andy, great info- thanks for the description! I have a couple questions about the following things:

1)Are you suggesting I let each layer of cloth dry completely, then sand, then lay the next one? My understanding is that if I were to lay subsequent layers in while the previous was still tacky, I get both a mechanical and chemical bond. True or false? 2)I read somewhere on here (Roger?) that a piece of PVC pipe (not sure what diameter) to shape the fillet is a good, simple method. Perhaps I could use the same piece of pipe instead of shaping a paint brush handle? If Im understanding you correctly, the purpose of this is to remove excess resin in the glass layup. Is that right? |

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 3:23pm Posted: January-17-2010 at 3:23pm |

|

Tim,

Your right if you can lay it up layer after layer wet that's best. Just if it does dry use 220 grit and flush off w/ acetone the to get the best surface prep. The excess resin that squeezes out of the lay up when you debulk is the by-product of the fabric nesting together. 40% resin 60% fabric by weight is a good ratio to shoot for. If you saw some of our parts you'd swear they were way to dry. I just layed up 42 test samples for tensile testing on Tues. I'm going to mess w/ my boat now. |

|

|

|

WakeSlayer

Grand Poobah

Joined: March-15-2006 Location: United States Status: Offline Points: 2138 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 3:32pm Posted: January-17-2010 at 3:32pm |

|

I used frosting spatulas to shape the fillets. Cheap and they leave a nice uniform, clean shape.

Edit: apparently they called "spoonulas" |

|

|

Mike N

1968 Mustang |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 3:33pm Posted: January-17-2010 at 3:33pm |

|

thats what makes a great recipe, a little of this and a little of that. and the same holds true for information. i just hate to see guys coating secondaries with epoxy or painting the hull with epoxy, it gets costly

|

|

|

"the things you own will start to own you"

|

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 5:52pm Posted: January-17-2010 at 5:52pm |

|

Hey Waterdog,

I've read posts where you've spoke about Airplane repair. Is there a lot of fiberglass on military or commercial planes? I don't know anything about airplanes except when I fly on them it all looks like riveted steel or aluminum. Just curious. BKH |

|

|

Livin' the Dream

|

|

|

|

Morfoot

Grand Poobah

Joined: February-06-2004 Location: South Lanier Status: Offline Points: 5320 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 7:00pm Posted: January-17-2010 at 7:00pm |

|

Brian, the answer to your question is YES. Todays commercial airplanes have ALLOT of composites in them. Mainly the flight control surfaces and engine cowlings and fairings. The skins are comprised of either carbon fiber or fiberglass skins with an aluminum honeycomb core and even sometimes the core is a fiberpaper that is coated in epoxy. The transitional farings from fuselage to wings are composite and some have an aluminized coating that is flame sprayed on them for that little impact damage prevention.

In my book I call it..............................JOB SECURITY! |

|

|

"Morfoot; He can ski. He can wakeboard.He can cook chicken.He can create his own self-named beverage, & can also apparently fly. A man of many talents."72 Mustang "Kermit",88 SN Miss Scarlett, 99 SN "Sherman"

|

|

|

|

Waterdog

Grand Poobah

Joined: April-27-2006 Location: United States Status: Offline Points: 2020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 9:41pm Posted: January-17-2010 at 9:41pm |

|

BKH,

The V22 Osprey is 80% composite, AV-8b Harrier is mostly composite. Rotor blades my gosh, a titainum spar like a hollow 2X6 down the lenght and a composite leading edge, blade pocket and tip cap. No adhesive likes to bond to titainum. In the desert we get very little time on a set of rotor blades. Lots of blades removed for over haul with less than 10 hrs. ($300,000)But the bad boy is the C-5a the biggest we have (reworked in Ga.)20,000 sq ft of bonded surfaces. |

|

|

|

bkhallpass

Grand Poobah

Joined: March-29-2005 Location: United States Status: Offline Points: 4723 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-17-2010 at 10:00pm Posted: January-17-2010 at 10:00pm |

|

Interesting. I've seen a lot of the photos of the stealth planes, and I guess thinking back, they don't look "metallic." Just never been close enough to notice. BKH

|

|

|

Livin' the Dream

|

|

|

|

TRBenj

Grand Poobah

Joined: June-29-2005 Location: NWCT Status: Offline Points: 21186 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-18-2010 at 9:10pm Posted: January-18-2010 at 9:10pm |

|

Ok, Ive detuned my glass order due to the changes. No more mat in the stringer/rib/bulkhead schedule. Added a bit more cloth tape for good measure. Got rid of the talc. Ive removed the incedentals for the time being- Im going to check Harbor Freight for them next time I pass by.

Revised plan: Before installation: - Main stringers (3 layers of ½”) will be laminated together with cloth - Front bulkheads will get a layer of cloth on both sides (to prevent buckling) - Floor panels will get 2 layers of cloth on the underside (for screw retention) Stringer Installation: - Mains will go in first, followed by secondaries, then bulkheads and ribs. - Mains and secondaries will be bedded with a combination of epoxy mat and epoxy resin thickened with mill fiber and cabosil (to take up the gaps). - Main stringer layup: 2 layers of 2" cloth, 2 layer of 4" cloth, 2 layers of 8" cloth, 1 layer of 12" biaxial. Top will be wrapped with the biax. May add a little mill fiber to the resin. - Secondaries: : 1 layer of 2" cloth, 1 layer of 4" cloth, 1 layers of 8" cloth, 1 layer of 12" biaxial. Not wrapped. - Ribs (alongside secondaries): Not bedded or filleted. 2”,4”,8” cloth tape only. Front bulkheads: Every other bulkhead will be bedded and get the same schedule as the primary stringers. Every other will not be bedded or filleted and will get a 2”/4”/8” cloth tape schedule (same as the ribs). Floor Installation: - Each panel will be bedded with epoxy mat or thickened epoxy (mill fiber/cabosil). Still undecided on which one (or both) and whether or not to use screws as well. - Filleted to walls with thickened resin (milled fiber/cabosil) - Taped to the wall with 2" cloth, 4" cloth and 8" cloth. - Taped to the secondaries with 2” cloth, 4” cloth, 8” cloth - The top of the floor will get 2 layers of cloth and one of mat, except up front where its foamed- which will get an extra layer of mat for thickness. The idea behind the reduced schedule (fewer layers of glass and no bedding) on the ribs and every other bulkhead came from my conversation with Joe. I have no problem with taking advice from those smarter than I am! The main idea is to prevent gel damage in the event of a hard strike (running the boat aground, bouncing on the trailer, etc) by allowing the hull to flex a bit during these situations. The coosa and glass schedules I have planned should be more than strong enough to support the floor and hull, even at 60+mph.

|

|

|

|

Keeganino

Grand Poobah

Joined: October-27-2009 Location: North Carolina Status: Offline Points: 2063 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: January-18-2010 at 10:00pm Posted: January-18-2010 at 10:00pm |

|

Tim

I want to see pictures for each step! Wish I was that far along. Still reading my way dizzy. Flotation ideas? |

|

|

|

Post Reply

|

Page <1 34567 31> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |