No Super Sucker needed |

Post Reply

|

Page <12345 7> |

| Author | |

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-20-2010 at 1:41pm Posted: April-20-2010 at 1:41pm |

|

Well Pete since our oldest tractor is a '47 my research has stopped there! You'd have to look at what some of the cars of the period used. How about the wire type like these # 10 in the pic, or were these used only by the English so that they would leak

? ?

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-20-2010 at 8:51am Posted: April-20-2010 at 8:51am |

|

Gary,

I looked at the tower style "Wittek" clamps and I seem to remember finding that they weren't used until the late 30's. Correct me if I'm wrong as you're into the tractors more that I am. It's a alternate! I did find the site you linked to. Lots of tractor stuff out there!! The two wire with the stove bolt is the other alternate I mentioned. They will take some work too. Since they don't come small enough, I need to modify the threaded anchor point on the wire by rolling the "pig tail" back on it's circumference. I've got my fingers crossed that Bob will open up one of his drawers and find a cache!! |

|

|

|

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-20-2010 at 1:34am Posted: April-20-2010 at 1:34am |

|

Pete,would not these be period correct also? I have a 3/4" one of the type in your pic's,it's yours if you need it.

Our older IH had a mag and they too have an impulse coupler,must have something to due with the hand crank as you say. The mag went bad in the early '70s,Dad needed the tractor asap and IH sold a distributor conversion so that was the end of that. |

|

|

|

Keeganino

Grand Poobah

Joined: October-27-2009 Location: North Carolina Status: Offline Points: 2063 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-20-2010 at 12:39am Posted: April-20-2010 at 12:39am |

|

Great work Pete. Looking good!

|

|

|

"working on these old boats may not be cost effective but as it shows its what it brings into your life that matters" -Roger

1973 Skier |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-19-2010 at 10:54pm Posted: April-19-2010 at 10:54pm |

|

Bob,

One of these day's you've got to clean out the left overs and put them on ebay!! A friend who rebuilds Chris engines and both sells and buys on ebay get's $5 each for rusty old Chris hose clamps! They are similar to the "Sherman" clamps but they have the thumb screw instead of the "stove bolt". Chris wanted the boat owner to be able to get the clogs out of the plumbing without needing tools!!! Here's some more pictures besides the other ones. I'm looking for 6 - 1" ID and 2 - 1&1/4" ID.

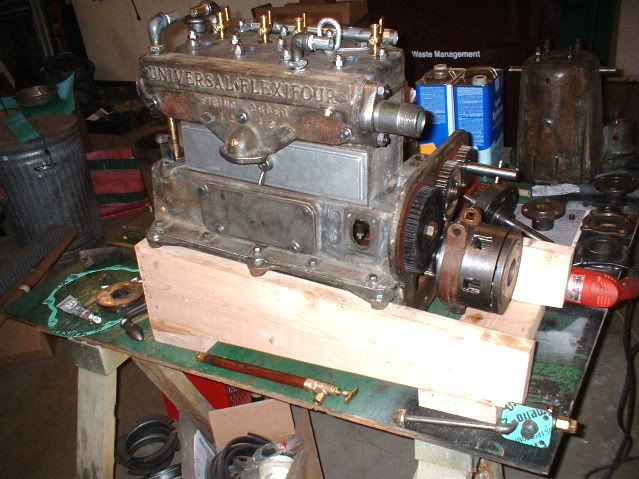

On another subject, I finally figured out the model of magneto I need. I went searching and found a guy in Cross Lake TWP. Maine. He got the business from his dad so he really knows his old magnetos. He's going to build one up for me but ouch, it's the most expensive part of this rebuilt/restoration!!! Period correct and looks just like the pictures I do have of the Flexi magneto equipped. It even has the proper mounting distances to the bracket on the engine. American Bosch DU4:

One thing I learned and found interesting is what a optional "impulse coupling" is on a mag. It's sort of a spring wound coupling that when a engine is hand cranked to start will wind up and then "pop" the magnet over TDC producing a hotter spark. When running, the spring in the coupling relaxes/normalizes and the mag runs normal. It's sort of the same as the ballast resistor bypass we have now!!! It's a must have option for a hand crank. |

|

|

|

Munday

Gold Member

Joined: August-17-2004 Location: United States Status: Offline Points: 538 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-19-2010 at 9:26pm Posted: April-19-2010 at 9:26pm |

|

Pete I'll look for some clamps like you need if you post a pic of the ones you want.Have 3 drawers full of clamps from the old shop.A minimum ID would help too.

Bob |

|

|

If the only tool you have is a hammer,everything starts to look like a nail.

|

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-19-2010 at 12:32am Posted: April-19-2010 at 12:32am |

|

that thing blowing smoke yet??? I'm on my 32ND cylinder since this project started. sometimes that old ***************e is a pita!

|

|

|

"the things you own will start to own you"

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-18-2010 at 9:55pm Posted: April-18-2010 at 9:55pm |

|

Moving along but I didn't get the trans back together. I forgot that the output shaft sun gear is at work waiting for me to press it on the shaft and it goes in next!!

So, I continued on with more small stuff.

I got the oil pump (in front on right) rebuilt with a new plunger spring and ball bearings for the check valves courtesy of McMaster! Faced the check ball seats and fabbed a new bronze pick up screen. It took some time to form into the cup shape and solder to it's base. The "super sucker" (front left) I rebuilt with a new rubber plunger and new stem packing. Here's the PITA front main seal. It's a rope seal (remember I got the Gortex to put in it) but not the easiest to get in there, with the gaskets and the Permatex all at one time. The split brass housing is also the front trust bearing for the crank - tight fit!! The actual brass split housings needed some work too. The hubs are riveted and soldered to the thin brass backing plates. There were a couple of spots where the joint was "cold" soldered. I ground/cleaned them out the best I could used a acid flux but I still worried about one spot. I ended up getting the JB weld out again!!

I went looking for period correct hose clamps. I found some NOS but the guy gets $30 each for them. I need 6 so it's on to plan "B" which is using the old two wire type. This is what they call a "Sherman" clamp:

Besides these chores, I continued on with the wire wheeling and cleaning up remaining parts. Fasteners are taking quite some time. Some needed the hex's ground because of rust. No, I can't run out and buy some of these original fasteners. All hex's are heavy heads (larger) and new heavy bolts start at 1/2" size. Others are cheese heads and that's not because they are made in Wisconsin!!! See the front main seal and you'll see the heads look like a wheel of cheese. |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-17-2010 at 8:36pm Posted: April-17-2010 at 8:36pm |

|

I'm making some progress getting the Flexi back together. Lots of small chores that do need to be done but take time like making gaskets or cleaning up all the small parts.

In preparation of getting the trans back on I did have a repair to make to the case. This was another mistake on my part but not as bad as busting the hub off the planetary housing. The shift fork is fastened to the shaft with one of those big square head set screws and it's dimpled into the shaft or at least that's all I could see. Unbeknown there was also a woodruff key under the fork. Well Thinking the shaft was just rusted in, I started to do some rather heavy hammering to get it out of the case. It was too late before I realized I had busted the boss out on the inside of the case casting. All ground out and cleaned up you'll see where the boss is broken out on one side where the woodruff key entered the bore. The piece of urethane wrapped with fine line tape inside the bore of the boss is a "mold" for good old JB Weld! I knew the epoxy wouldn't stick to the tape and the urethane is soft enough so I felt it would come out easy. I "primed" the spot with the JB and then went over it with a 2 part epoxy putty.

Here's the repair finished and boss reamed.

|

|

|

|

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-09-2010 at 11:38am Posted: April-09-2010 at 11:38am |

just cut and paste |

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-09-2010 at 9:52am Posted: April-09-2010 at 9:52am |

|

I wanna know how 79 came up with the "R" and the "TM" symbol

|

|

|

"the things you own will start to own you"

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 5:24pm Posted: April-08-2010 at 5:24pm |

|

Chris,

Thanks for the proceedure. I guess I've been wasting the stuff through the years! I already had the 262 at home as well as the 290. With my last order to McMaster for the bolt, nuts, some sheet gasketing, etc. I ordered the 243 which is medium and considered removeable. That's what I plan on using. 262 is removeable and really not permanant. It just needs to be heated to about 450 F which actually is below the tempering temp of steel. We do it on a regular basis here at the plant on a couple of assemblies. Never had a issue and we re use the fasteners. |

|

|

|

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 5:16pm Posted: April-08-2010 at 5:16pm |

|

Loctite® Threadlocker 262™ (Automotive Aftermarket Only) is a permanent, high strength, red threadlocker that is applied to fasteners up to 3/4" (20 mm) in size before assembly.

clip from henkel's website regarding 262 loctite. You really don't want to use this Pete. Call Henkel they are very customer oriented and will send out samples to about any company for free. They also have classes (1 and 2 day) with college credit to boot, periodicly as well for free |

|

|

|

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 4:28pm Posted: April-08-2010 at 4:28pm |

well yea you did, kinda waisting the product, but on a blind hole let it drip on one side of the threaded hole in a straight line so to say, then insert the bolt, the air forces it back up around the thread as you screw in the bolt. On a thru hole just apply a line of the product starting a couple threads up from the end of the bolt and your good to go. No need to run it in then back out again and re-inserting, you've basically wiped it clean and have decreased the effectiveness of the loctite. It cures by the lack of air so it needs to fill the space between the threads for it to cure, by inserting removing and reinserting the product is thinned out and creates gaps so there is always air present so it doesn't cure. FYI if you plan on ever dis-assembling the rod caps you don't want to use the red stuff aka 262 it is perminate. |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 4:14pm Posted: April-08-2010 at 4:14pm |

|

Chris,

I never really knew there was a recommended procedure. I usually put it on both and then run the screw in and out a couple times to make sure the thread locker is on all the treads!! Did I flunk threadlocking 101?

|

|

|

|

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 4:09pm Posted: April-08-2010 at 4:09pm |

|

Here's one for you,

What is better when dealing with a blind thread, appling loctite to the holes threads or the screws threads? |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 4:00pm Posted: April-08-2010 at 4:00pm |

|

Chris,

Thanks for the advice. It was enough to "kick" me over the edge on going with the higher strength plus it also claims to be better with oil resistance. Now I just need to use the multiplier for the correct torque. BTW, I've used alot of the wicking type on smaller finer threads and it does really work great. |

|

|

|

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 2:14pm Posted: April-08-2010 at 2:14pm |

|

apply it before, don't use the wicking stuff very thin, you might as well not use any if your going to use the wicking version.

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-08-2010 at 1:15pm Posted: April-08-2010 at 1:15pm |

|

I got my new rod bolts made. I bought grade 8 bolts and nuts, cut the bolts to the two different lengths needed and ground the flats on the heads to match the type A rod bolt head. This time, I'm not going to over torque them!!

One thing I just lucked out with is the thread length on these grade 8 partially threaded bolts. It's one spec that you have no control over. The manufacturing tolerance for the actual length of thread is real sloppy. On a 5/16" x 2&1/4" bolt it's anywhere from 7/8" to 1&1/8". On one rod I have .010" thread left over!!! The other 3 I have .050" or better. I sure didn't want to have to put any flat washers under the nuts if at all possible. I haven't decided which Loctite to use yet. The self wicking after assemble medium strength or the high strength before assembly? |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-05-2010 at 12:27pm Posted: April-05-2010 at 12:27pm |

Eric, Do you use the loctite that is designed to wick in after assembly so it doesn't affect the torque reading or do you pre loctite and use the torque multiplier for lubricated/coated threads? The self wicking (apply after assembly) is considered a "medium" strength. I have it at home but along with the grade 8 bolts I'm ordering, I'm also getting the 262 loctite. It's considered "high" strength, 300 degree and states it's resistant to oils. All of the loctite brand thread lockers have a temp range up to 300 except 1 which is 450 but it seems to be for large bolts. |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-04-2010 at 12:26pm Posted: April-04-2010 at 12:26pm |

|

Gary,

I did look at the ARP but couldn't find a rod bolt smaller than 3/8. These are 5/16 x 1&3/4" and 2&1/8" (fine thread 24 pitch). The different lengths must have something to do with the splash lube as the rod revolves through the oil splash tray in the oil pan.

They do have what appears to be the type "A" head which is just the flat on one side.

The original bolt shanks are not tight fitting in the rod or the cap so it looks like I'll be just going with partially threaded grade 8 bolts and nuts. Chris and Eric, I looked up the temp limit on the locktite. I'm leaning towards it now. I could go with the self wicking/after assembly so it wouldn't affect the torque reading or just go with the regular??? Interesting on the torque - due to the fact that I don't have any for this engine, I've been using the torque specs for a later model flat head. Torquing to 40 Ft. Lbs. !!! I've been over torquing  because those are 3/8 and not 5/16"!! I may have done the same to the mains?? I should have gone directly to the SAE spec book and not this other engine manual. because those are 3/8 and not 5/16"!! I may have done the same to the mains?? I should have gone directly to the SAE spec book and not this other engine manual.

|

|

|

|

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-04-2010 at 11:29am Posted: April-04-2010 at 11:29am |

|

normally a standard nut torqued shouldnt loosen, on rods I always loctite, thats me though, never loctite on mains because they are stationary. i think some of the loctites are good to 350 degrees.

damn Pete, i do see the basic similarities between Joe's and Paragon's. I did not know Paragon went back that far |

|

|

"the things you own will start to own you"

|

|

|

|

Gary S

Grand Poobah

Joined: November-30-2006 Location: Illinois Status: Offline Points: 14096 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-04-2010 at 2:23am Posted: April-04-2010 at 2:23am |

|

Pictures? sizes? Distorted threads would be out,no way to tell torque setting. Maybe ARP has something you can use.

|

|

|

|

SNobsessed

Grand Poobah

Joined: October-21-2007 Location: IA Status: Offline Points: 7102 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-04-2010 at 12:48am Posted: April-04-2010 at 12:48am |

|

High temp locktite?

|

|

|

“Beer is proof that God loves us and wants us to be happy.”

Ben Franklin |

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: April-03-2010 at 7:13pm Posted: April-03-2010 at 7:13pm |

|

I need some help with connecting rod nuts/bolts. I'm pulling threads on the old ones. A couple of the nuts let loose and one of the bolts. I figure I had better replace all of them. The bolts are specific due to their heads. They simply have one flat ground on a round head mating with a flat on the rod. I can make them by grinding one of the flats larger on a grade 8 hex head but am wondering about the nuts. It's been awhile since I've seen the bottom side of a modern engine so wears the question. What means of locking or what type of nuts are used?? The originals are castlated with cotter pins. I'm thinking about a "flex top" or a "distorted thread" nut. Even though the specs say up to 250 degrees, I have a feeling a Nyloc may not like the heat but I'm open to suggestions.

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-31-2010 at 10:19am Posted: March-31-2010 at 10:19am |

|

Eric,

The trans isn't a Paragon but rather a Joes!

I sure wish I had found this cross section view BEFORE I put the crank and planetary in the press and broke the housing!! BTW, I had asked you if you knew how far back Paragon went. I found this picture from 1917 showing a Paragon in one of their adds. This was in the early days when the trans's were "add-ons", not cased and were simply put in line with the prop shaft. Even more alignment with the good old wood wedges!!

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-29-2010 at 7:58pm Posted: March-29-2010 at 7:58pm |

|

Did some machining at lunch today. As mentioned, Saturday I set the exhaust/intake manifold up against it's mating surface on the block and it wobbled/rocked! I got the straight edge out and I guessed the middle surface to have a belly of .030 in it. Maybe they didn't season this casting long enough! There's no indication of it being overheated. Dial indicated it in to the mills table and sure enough it was .028 low in the middle!

On the left is the flywheel. Last week I was looking at the rust pitting on one side of both the faces and the outside. I figured I could Bondo it or chuck it up in the lathe. I ended up in the lathe taking about .020" off to clean it up. Now I've got the high speed version of the Flexi with the light weight flywheel.

The brass leaning against the cork gasketing is the front main seal housing!! Inside of it's center is a groove for rope packing. Since everyone including myself has had such good luck with the GFO packing for a prop shaft gland, I figured I'd give it a try. High lubricity and a very high FPM rating (not that it's needed on a 2500 WOT engine!!) The spool to it's left is 5' of 3/16 Gortex GFO I purchased from McMaster for $26. Sure cheaper than Skidim! I price compared and Skidim's package claimed to be 24" but I sure didn't get that much when I bought it it. I think I was lucky to get 5 rings cut for the 1" prop shaft! The engine didn't come with a hand crank and figuring I'm going to have to turn it over soon, here's the forged crank I purchased that's very appropriate looking. I got the center of the hub drilled out and now I do have to mill the slot in it's end for the pin engagement to the cranks shaft.

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-28-2010 at 9:04pm Posted: March-28-2010 at 9:04pm |

|

Brian,

Yes we have wire machines as well as machining centers. Thanks for the offer The problem is really how much time do I really what to spend on the old pump. The old housing could be rebored for the gears and bored/bushed for the shafts but then it's the gears! We do not have the gear hob so we're talking having a set of custom oversize ones made or I go out and buy a hob!!$$$ If I can't find the rubber impeller to fit and see if I can get the original housing to work, then I have a friend who has already offer to give me a NOS Jabsco gear pump of the next generation. Mounting would be the only project as they were foot mounted whereas you'll notice in the pictures the existing was face mounted. It will be interesting to see if Depco comes up with anything. I've got several choices/options!! |

|

|

|

hotboat

Gold Member

Joined: March-28-2009 Location: Conn Lake Pa Status: Offline Points: 814 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-28-2010 at 8:18pm Posted: March-28-2010 at 8:18pm |

|

Pete, do you have wire edms at your disposal? If not and I get a slow spot at work I could whip up some new ones. What material and thickness are they and how do they attach to the shaft? I cant tell exactly what I am looking at in the pictures.

|

|

|

Brian

|

|

|

|

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: March-28-2010 at 7:49pm Posted: March-28-2010 at 7:49pm |

|

Can't find a rubber impeller that will fit. Looking over some rubber impeller pump, it looks like the cavity ID. is about 1/8" smaller than the impeller that goes in it. The existing gear pump cavity is 1&3/4" so I've been looking for a 1&7/8" impeller. Thickness (depth of cavity) is 1". I'll keep looking because I feel the conversion to rubber is a great idea. Besides, I don't have much hope in Depco coming up with parts. Another alternate is to take a newer style Jabsco gear and modify the mounting to fit. Of course that wouldn't even look original!!!

|

|

|

|

Post Reply

|

Page <12345 7> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |