Prop shaft strut bearings |

Post Reply

|

Page 123> |

| Author | ||

slalomjunky

Groupie

Joined: August-25-2008 Location: United States Status: Offline Points: 42 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Prop shaft strut bearings Topic: Prop shaft strut bearingsPosted: September-23-2008 at 4:44am |

|

|

question about strut bearings. Has anyone replaced one themselves? Is it a bad job if you have a puller? any strut damage by using a puller such as the one listed on skidims site? Skidims bearings are also 2 pieces instead of 1 4". Is this a better system or is it just for convenience pressing them in? Once the set screws are loosened and with use of a puller are the bearings easy to get out? what about removal of the shaft coupler from the shaft? is it worth attempting myself or having a mechanic do it?

|

||

|

Utah '94 Ski, '03 Malibu SS LXI

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-23-2008 at 8:50am Posted: September-23-2008 at 8:50am |

|

|

Kerry,

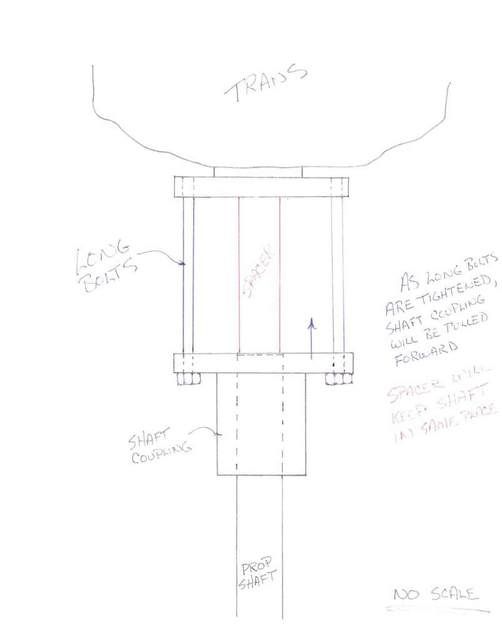

I really don't think many people get that puller to remove the old cutlass bearing. I as well as most will cut them out by using a hack saw. Put the blade through the shaft bore and assemble it on the saw frame. Doesn't take much cutting. I haven't heard of any advantages of the two piece bearing design. I feel the engineering concept is to get the forward section as far forward in the strut as possible to reduce possible prop shaft whip. I'd just go with the standard 4". Yes, the coupling removal from the shaft can be a challenge. The bore to the shaft is a interference fit so a puller is needed or most will use the "spacer and long bolt trick". This is a old sketch showing long bolts but threaded rod is even better - you just keep running the nuts up instead of having to change to shorter bolts!

Now, if you do take on this job, (we'll be here to help) and you find the coupling to be loose on the shaft, then you have fretted the coupling/shaft due to running with it misaligned. A new coupling and possibly a new shaft is needed. BTW, with the shaft out, it's a great time to check it for straightness. Getting the coupling back on the shaft requires the coupling to be heated so it expands. This PITA is why the double taper ARE shaft/coupling systems are so popular! (easier to remove too!) Keep us informed. |

||

|

||

M3Fan

Grand Poobah

Joined: October-22-2005 Location: United States Status: Offline Points: 3185 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-23-2008 at 9:55am Posted: September-23-2008 at 9:55am |

|

|

Ah- putting the blade through, THEN assembling the saw- brilliant idea. Would have saved me probably a full hour of cutting. I was just hand holding a blade using one of those little blade handles. For next time, I guess.

|

||

|

2000 SN GT40 w/99 Graphics/Gel

2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

||

|

||

anthonylizardi

Gold Member

Joined: July-25-2007 Location: DFW, TX, USA Status: Offline Points: 836 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-23-2008 at 5:12pm Posted: September-23-2008 at 5:12pm |

|

|

I tried a bolt puller and beating the heck out with an air hammer. The only thing that worked like a charm was the long bolt with the socket in between. Make sure you adjust the bolts evenly. I had an impact gun set in the lowest setting. It speed up the process. After that and finding my shaft was bent I bought an ARE.

|

||

|

||

slalomjunky

Groupie

Joined: August-25-2008 Location: United States Status: Offline Points: 42 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-23-2008 at 6:57pm Posted: September-23-2008 at 6:57pm |

|

|

8122pbrainard,

thanks for the info. I understand the spacer and long bolts. Is the spacer pushing against the trans shaft or is that half of the coupling solid and the spacer is pushing against the coupling only? any problem cutting into the strut while cutting the bushing? My experience with doing this type of operation is that the saw blade has just enough deflection to cut at each end and not as much in the middle of the 4in bushing. after cutting what are you using to push out bearing? |

||

|

Utah '94 Ski, '03 Malibu SS LXI

|

||

|

||

M3Fan

Grand Poobah

Joined: October-22-2005 Location: United States Status: Offline Points: 3185 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-23-2008 at 7:15pm Posted: September-23-2008 at 7:15pm |

|

I just went though this. On the trans side, that half of the coupling is bolted in with a giant bolt. At least it is on my PCM PP trans. It's tough to avoid cutting into the strut but a little bite into the strut bore won't hurt anything. |

||

|

2000 SN GT40 w/99 Graphics/Gel

2016 SN 200 OB 5.3L DI https://forum.fifteenoff.com |

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-23-2008 at 7:35pm Posted: September-23-2008 at 7:35pm |

|

|

Kerry,

Don't worry about the trans end, I've never had a problem nor have I ever heard of one. Maybe Eric has but I've never heard him comment on it. Just as Joel mentioned, don't worry about nicking the strut ether. Yes the saw blade may deflect and you may rock slightly with the sawing. Start with a new blade that isn't bent already. What I try to do is cut almost through the old case of the cutlass and then using a cold chisel or punch, curl the bushing inwards on itself - then cut some more. Grab it with a vise grip and it will pull right out. Now, getting the new one in is easy. Use a piece of threaded rod nuts and fender washers on the ends to press it in. You can tap it in with a block of wood and hammer but be very careful! |

||

|

||

behindpropeller

Platinum Member

Joined: July-31-2006 Status: Offline Points: 1810 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-24-2008 at 11:41am Posted: September-24-2008 at 11:41am |

|

|

I have a puller I made...

I will lend it out if you want. Tim |

||

|

|

||

|

||

slalomjunky

Groupie

Joined: August-25-2008 Location: United States Status: Offline Points: 42 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 3:44am Posted: September-25-2008 at 3:44am |

|

|

I appreciate all the info. Nice to get a lot of knowledge before starting a project like this. do any of you ever get parts from go2marine.com? I was on their site and they have a 4" bushing(one piece) on sale for $49.11. are there better/worse quality depending on manufacturer? Once I have all hte prep work done and am ready to pull shaft aprt and complete the instal how long will it realistically take me? what about realigning the shaft to engine? I attached the info on the bushing from go2marine.

Rubber Sleeve Stern Bearings - Naval Brass Mfr. Duramax Marine $49.11 - $283.00 Full molded type Duramax rubber-lined Naval Brass Sleeve Bearings adapt equally well to strut and stern-tube mounts and are often used effectively as rudder-stock and pintle bushings Bearing diameters are precision fitted to the designated shaft size with the correct clearance for efficient water lubrication External brass shells are machined and polished to provide easy fitting Specially formulated oil and chemical resistant nitril rubber is securely bonded to the shell Units with thin shells are available for the struts of small craft Sleeve Bearings are usually install by light press-fitting and locked in place with cone-pointed set screws |

||

|

Utah '94 Ski, '03 Malibu SS LXI

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 7:50am Posted: September-25-2008 at 7:50am |

|

|

Kerry,

I've used Go2 several times without any problems. They seem to carry all the good brands at very good prices. Yes, That's the traditional cutlass bearing you found. As far as the time it will take you to do the job, that's a tough one! There are too many variables. To R&R the shaft will take the time. 2 hours to all day?? Are you planning on putting your old shaft back in? Do check the shaft fit to the coupling and check the shaft for straightness. The best way is with the shaft set in V blocks and then a dial indicator. Now, strut/shaft/log/engine alignment?? When you get the shaft out and before you start cutting out the bearing, take a look at the wear pattern on the ID of the bearing. It's a good indicator of a bent or misaligned strut. |

||

|

||

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 10:18am Posted: September-25-2008 at 10:18am |

|

|

one bit of advice when cutting into the strut, cut into it at the 12 O'clock position where all the meat of the strut is in case you cut to deep. I have tried many times with a puller to pull these bearings and its almost impossible, the best method is cutting them with a sawzall and 10" fine metal blade

|

||

|

"the things you own will start to own you"

|

||

|

||

slalomjunky

Groupie

Joined: August-25-2008 Location: United States Status: Offline Points: 42 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 1:16pm Posted: September-25-2008 at 1:16pm |

|

|

Eric,

makes sense to cut at that position but definitely a little harder to see and apply the right amount of pressure. Are you first cutting out the rubber portion to be able to get a good look at the brass and not to bind the blade? Pete, I understand that usual wear is on the bottom. do you realign like this or try to correct to have more even wear? What is the best way to move engine? Rear mounts do have threaded height adjustment but not lateral. I have never hit anything, no dings in prop at all ever. Should i still be worried about bent hardware? shaft should go through the direct center of shaft log correct? How is adjustment made for this if it is off? the waterseal and hose which hold it will be basically alignining the shaft from the strut to the log. I can't see how this can be changed much, rather engine has to be moved to align, corrrect? am I missing something? thanks Kerry |

||

|

Utah '94 Ski, '03 Malibu SS LXI

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 1:43pm Posted: September-25-2008 at 1:43pm |

|

|

Kerry,

Yes under normal conditions most of the wear on the cutlass will be on the bottom. This this from the force of the water against the hull pushing down on the prop/shaft. Look for uneven wear top to bottom and port to starboard. This would indicate that the shaft isn't parallel to the bore of the strut. Yes, the strut can be aligned by using flat washers to shim the base to the hull. They can also be bent or twisted back to normal. Prop shops usually do this or someone with a press. The key thing is you want the shaft to be roughly centered in the hole in the hull/shaft log. This will be by putting the shaft in the new bushing and then feeling (by turning) the shaft to find where it's comfortable meaning it's close to parallel. Hopefully it will then line up with the hole. You don't want to pull the strut unless absolutely necessary. Have you run across Eric's pictorial thread on engine/shaft alignment yet? If not, I'll find it and give you a link to it. If you haven't aligned lately, I strongly recommend it. |

||

|

||

anthonylizardi

Gold Member

Joined: July-25-2007 Location: DFW, TX, USA Status: Offline Points: 836 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 2:42pm Posted: September-25-2008 at 2:42pm |

|

|

Kerry,

If you can while you have the shaft out check the aligment. My strut was bent and the shaft was straight except at the end. This how I checked it using an almost V-block: shaft aligment Good luck |

||

|

||

behindpropeller

Platinum Member

Joined: July-31-2006 Status: Offline Points: 1810 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-25-2008 at 3:53pm Posted: September-25-2008 at 3:53pm |

|

Took me 25 minutes to get mine out with the puller I made. No cutting. |

||

|

|

||

|

||

eric lavine

Grand Poobah

Joined: August-13-2006 Location: United States Status: Offline Points: 13413 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 10:13am Posted: September-26-2008 at 10:13am |

|

|

the last one i did didnt budge with heat and the tool, it started to mushroom the bearing,

i always atempt with the tool first but always end up with the saw, once in a while they will slide right out with the tool....then that means the new one slides in loose and get out the locktight |

||

|

"the things you own will start to own you"

|

||

|

||

behindpropeller

Platinum Member

Joined: July-31-2006 Status: Offline Points: 1810 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 11:28am Posted: September-26-2008 at 11:28am |

|

|

I have a threaded puller, not a slide hammer like ARE sells.

I did put the new one in with red loctite....hope I never need to get it out!!! Tim |

||

|

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 11:49am Posted: September-26-2008 at 11:49am |

|

|

The brass wall thickness of the cutlass being very thin (.040 to .050??) it really doesn't give much of a surface for the puller plate to grab. If there is any corrosion between the strut and cutlass and or burrs from the set screws it sure makes pulling them a challenge. I've even had issues with getting the set screws loose. They are a shallow socket head and not much bite for the allen wrench. At least the allens are better than the early slotted soft brass ones!!

If the puller works, great! If not then saw it out. I personally feel sawing is quicker. Defiantly if you have the Sawsall. |

||

|

||

slalomjunky

Groupie

Joined: August-25-2008 Location: United States Status: Offline Points: 42 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 1:14pm Posted: September-26-2008 at 1:14pm |

|

|

Sounds like I will have a great time with this project. If it is loose comming out and going in are you putting loctite on the exterior brass surface of the bearing? or just on the set screws? What about shaft wear st the bearing site? anything in particular to look for?(except for the obvious) Is factory alignment of the strut usually pretty good? and maybe I won't have to worry about the strut alignment with the shaft log(I Hope). Thanks for all the advice. when I get the time this fall I will have to get this project going and see how it goes. I have not run across the pictorial alignment thread. That would be nice to see if you can find the like I would appreciate it. thanks Kerry

|

||

|

Utah '94 Ski, '03 Malibu SS LXI

|

||

|

||

79nautique

Grand Poobah

Joined: January-27-2004 Location: United States Status: Offline Points: 7872 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 1:30pm Posted: September-26-2008 at 1:30pm |

|

WELL that doesn't sound too bright since it's a service item and will need replaced again at some time. |

||

|

||

anthonylizardi

Gold Member

Joined: July-25-2007 Location: DFW, TX, USA Status: Offline Points: 836 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 1:31pm Posted: September-26-2008 at 1:31pm |

|

Tell about the shallow socket head. I stripped both of them. I didn't want to deal with this and since I was sending the strut to get it straight I pay them to remove the set screw. Tell about the shallow socket head. I stripped both of them. I didn't want to deal with this and since I was sending the strut to get it straight I pay them to remove the set screw.

|

||

|

||

critter

Platinum Member

Joined: January-11-2008 Location: New Hill, NC Status: Offline Points: 1227 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 1:39pm Posted: September-26-2008 at 1:39pm |

|

|

1980 Ski Nautique

1966 Barracuda |

||

|

||

behindpropeller

Platinum Member

Joined: July-31-2006 Status: Offline Points: 1810 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: September-26-2008 at 4:34pm Posted: September-26-2008 at 4:34pm |

|

Thats what a torch is for. |

||

|

|

||

|

||

WakeSlayer

Grand Poobah

Joined: March-15-2006 Location: United States Status: Offline Points: 2138 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-16-2008 at 4:32pm Posted: October-16-2008 at 4:32pm |

|

|

I am about to begin doing some maintenance stuff on the Mustang.

- Shaft and rudder packing, as I take on a little water. - steering cable - cleaning up the wiring - cutlass bearing, and alignment and a few other little items. I looked at the cutlass bearing last night, and it is perhaps half (maybe less) worn just on the bottom end and fine the rest of the way around. The propshaft spins freely from the prop and from the trans coupler with hardly any effort at all. The coupler is perfectly aligned all the way around. My question is; Do I really need to replace the cutlass bearing in that condition? I already have it, and the threaded rod to make a puller, so cost is no issue. When is it required ? PS: Pete, thanks for the diagram!! |

||

|

Mike N

1968 Mustang |

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-17-2008 at 11:12am Posted: October-17-2008 at 11:12am |

|

|

Mike,

Generally if you can move the prop shaft up & down and side to side then it's time for a new cutlass. Wear on the bottom only is normal. It's from the water (prop wash) hitting the hull causing more downward pressure on the prop/shaft. Make sure the wear is even and not opposite (aft-bottom, forward-top) which would indicate a strut to hull misalignment. You can have a misaligned strut to the hull and still have good engine to shaft alignment! |

||

|

||

WakeSlayer

Grand Poobah

Joined: March-15-2006 Location: United States Status: Offline Points: 2138 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-17-2008 at 12:38pm Posted: October-17-2008 at 12:38pm |

|

|

Thanks Pete. I will look and the fore part of the shaft with a mirror this weekend. I have an very teeny vibration, but suspect the propeller after inspecting it. I want to learn to do this stuff, but not if there is no reason to. I can always do it later. It turns so freely that i have to question whether it needs it.

I have a second question about the packing. I had bought a length of 3/16 Gore-tex packing. Is this correct for the 1" shaft on a Mustang/289? Can I also, get a brief explanation on how to to the shaft and rudder packing? I think I have it figured out, but.... |

||

|

Mike N

1968 Mustang |

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-17-2008 at 1:16pm Posted: October-17-2008 at 1:16pm |

|

|

Mike,

Since you mentioned the shaft turning very freely (a second time) do take a close look at the cutlass again. It may be time - the cutlass itself will produce drag on the prop shaft. You are going to need the 1/4" packing. I can't remember the years of the 3/16". Tim has mentioned them but it was a lot later (late 80's?) than your 68 The packing is wrapped arount the shaft in 360 degree segments. The ends of the segments are staggered 180 degrees. It usually takes about 4 segments to fill the packing gland. Don't overtighten the nut. Let it run (wet) and then tighten it if needed. The gland may run warm at first but never hot. If it gets hot, then the nut is too tight. |

||

|

||

WakeSlayer

Grand Poobah

Joined: March-15-2006 Location: United States Status: Offline Points: 2138 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-17-2008 at 1:53pm Posted: October-17-2008 at 1:53pm |

|

|

When I say freely, it is not "loose" just doesn't take more than light pressure to spin it. And it is smooth turning as well. There is no play in the bearing either.

I will call and get the 1/4 going. thanks |

||

|

Mike N

1968 Mustang |

||

|

||

gcarbone

Groupie

Joined: October-13-2008 Location: United States Status: Offline Points: 95 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-20-2008 at 3:11am Posted: October-20-2008 at 3:11am |

|

|

Besides being able to move the prop shaft up and down and side to side while its in the trailer - are there any performance symptoms when the boat is in the water to help determine if you need a new cutlass bearing?

|

||

|

||

8122pbrainard

Grand Poobah

Joined: September-14-2006 Location: Three Lakes Wi. Status: Offline Points: 41045 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: October-20-2008 at 7:43am Posted: October-20-2008 at 7:43am |

|

A worn cutlass will cause vibration as well but vibration can also come from a bad shaft and or prop. Out of the water inspection is best. |

||

|

||

Post Reply

|

Page 123> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |